Copper tubes can be classified by material into red copper tubes (pure copper), brass tubes (copper-zinc alloy) and bronze tubes (copper-tin alloy). Among them, red copper tubes are widely used in refrigeration, HVAC and water supply systems due to their thermal conductivity, corrosion resistance and ductility. According to the production process, they are divided into seamless copper tubes and welded copper tubes. Seamless tubes have a stronger pressure-bearing capacity and are suitable for high-pressure environments. The natural antibacterial property of copper pipes makes them an ideal choice for drinking water pipes. Meanwhile, their resistance to high and low temperatures (-196℃ to 250℃) also makes them suitable for working conditions.

Definition and Characteristics of Copper Tubes

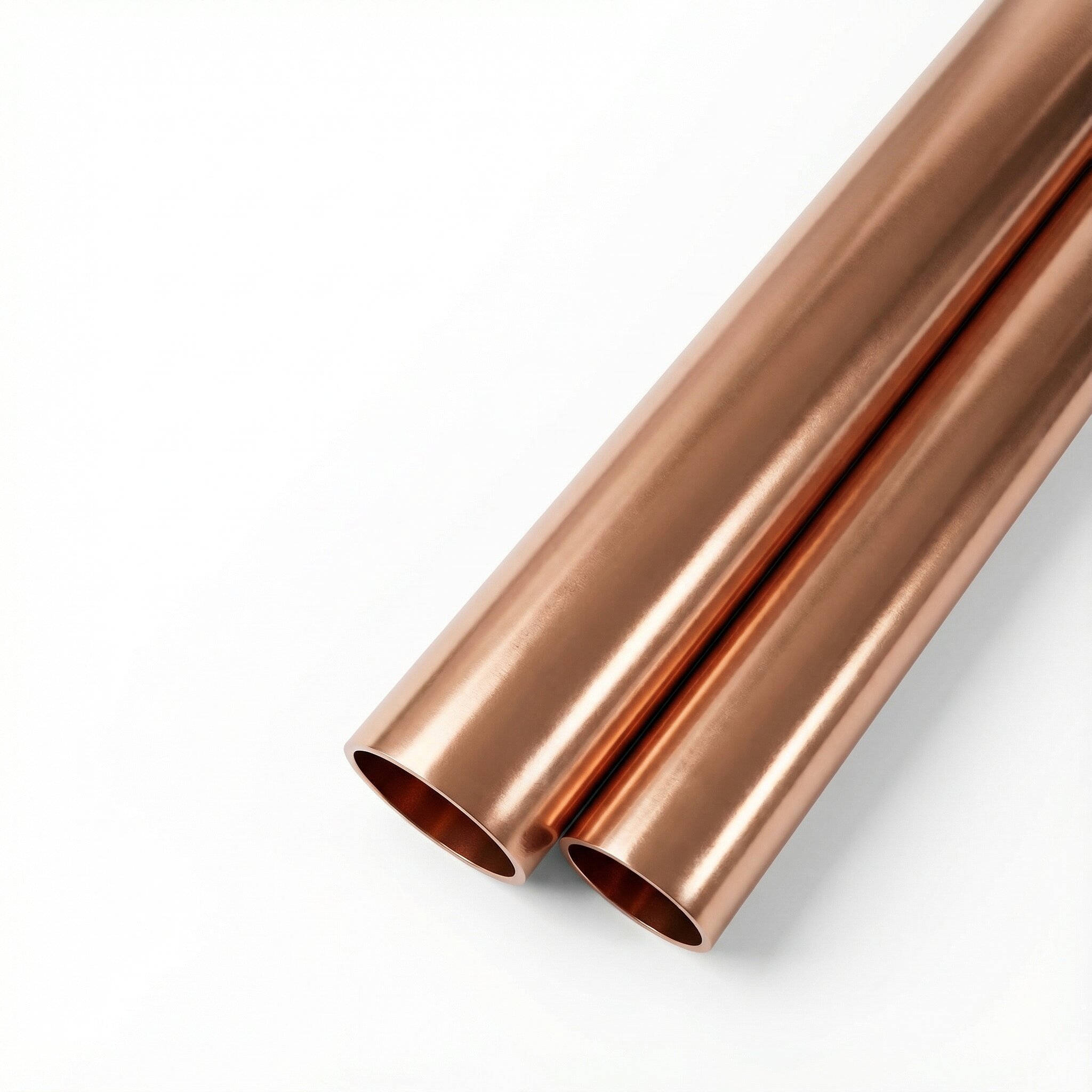

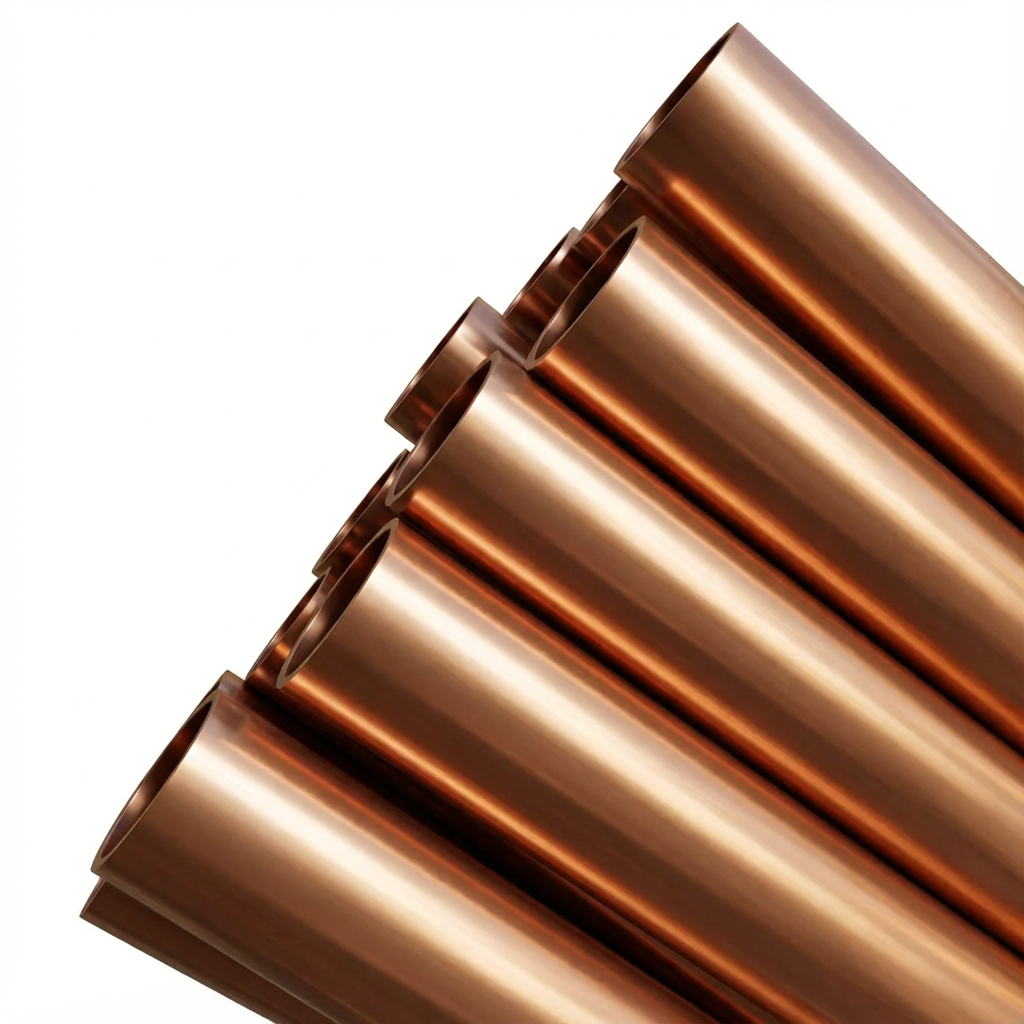

Copper tubes are hollow metal tubing made primarily of high-purity copper, possessing excellent thermal conductivity, electrical conductivity, corrosion resistance, and ductility. The copper purity is typically above 99.9%, with commonly used materials including oxygen-free copper (C10200) and phosphorus-deoxidized copper (C12200), which differ slightly in processing performance and corrosion resistance. Based on their structure, copper tubes are mainly divided into seamless copper tubes and welded copper tubes. Seamless copper tubes are directly manufactured through extrusion or perforation, resulting in a seamless tube body, dense structure, and good pressure resistance, commonly used in refrigeration and high-pressure systems. Welded copper tubes are made by rolling and welding copper strips, offering high production efficiency and lower cost, and are widely used in building water supply and gas transmission. In terms of shape, they can be divided into round tubes, rectangular tubes, flat tubes, and coiled tubes to meet different installation and heat exchange requirements.

Copper tubes possess exceptional overall performance: their thermal conductivity is approximately 400 W/(m·K), ranking among the highest of all engineering metals; they exhibit excellent corrosion resistance, forming a dense oxide film in water and air; they are highly ductile, easy to bend, weld, and process, facilitating construction; their smooth surface and strong antibacterial properties inhibit bacterial growth, making them widely used in drinking water systems and medical piping networks. Copper is highly recyclable, with a recyclability rate of 99%, meeting the requirements of energy conservation, environmental protection, and sustainable development. These characteristics determine that copper tubes remain an irreplaceable key metal tubing material in modern construction, refrigeration, energy, electronics, and transportation industries.

Manufacturing Process and Product Standards of Copper Tubes

The manufacturing process of Copper Tubes is precise and systematic, typically including melting and casting, extrusion molding, cold drawing, annealing and heat treatment, pickling and cleaning, inspection, and packaging. First, electrolytic copper is melted into liquid copper, which is then continuously cast or die-cast into copper rods or tube blanks. These are then extruded at high temperatures to form a preliminary tube shape. Multiple cold drawing and sizing processes ensure dimensional accuracy and surface quality meet standard requirements. To improve plasticity and flexibility, the finished Copper Tubes undergo annealing. They are then pickled and cleaned to remove surface oxides, and finally cut, inspected, and packaged for shipment. Advanced production lines are also equipped with online eddy current testing systems to ensure the absence of cracks, porosity, and uniform wall thickness.

Copper Tube production and inspection are subject to strict international and national standards. Common standards include ASTM B88 (copper pipes for building construction) and ASTM B280 (copper tubes for refrigeration) from the United States, EN 1057 (water and gas systems) from Europe, JIS H3300 from Japan, and GB/T 1527 (seamless copper tubes) and GB/T 18033 (copper tubes for refrigeration) from China. These standards have specific requirements for composition, mechanical properties, dimensional tolerances, airtightness, and cleanliness. Common copper tubes have an outer diameter of 4–108 mm and a wall thickness of 0.5–5 mm, and can be manufactured in 5-meter standard lengths or 15–30-meter coils. In recent years, continuous advancements in automated production, precision control, and surface treatment technologies have led to continuous improvements in the dimensional accuracy, surface quality, and internal cleanliness of copper tubes, meeting the application requirements of high-end equipment and medical systems.

Main Applications and Market Demands of Copper Tube

Copper tubes have a wide range of applications and are a fundamental material in the HVAC, refrigeration, building water supply, electrical, automotive, and medical industries. In refrigeration and air conditioning, copper tubes are primarily used in condensers, evaporators, and connecting pipes, improving heat exchange efficiency and system reliability due to their excellent thermal conductivity and pressure resistance. In building and municipal engineering, copper tubes are used in hot and cold water systems, gas pipelines, and heating systems, offering good corrosion resistance and sealing while meeting hygiene and safety standards. In the electrical and electronic industry, copper tubes are used in conductive connectors, busbars, and motor winding cooling systems; in the automotive industry, they are widely used in air conditioning piping, engine cooling, and braking systems.

Copper tubes have unique advantages in the medical and scientific research fields. Due to their antibacterial properties, they are often used in medical gas delivery, vacuum systems, and laboratory gas networks. With the development of renewable energy, copper tubes have also become a key heat exchange material in equipment such as solar water heaters and air source heat pumps. The growth of the global copper tube market is mainly driven by the following factors: first, the acceleration of urbanization and the continuous expansion of demand for building and refrigeration; second, energy conservation and environmental protection policies promote the application of high-efficiency heat exchange materials; and third, consumers' preference for high-quality, safe and durable pipes has increased.

Copper Tube Industry Trends and Corporate Practices

The current copper tube industry is developing towards higher efficiency, intelligence, and sustainability. A company's ability to integrate new technologies and the industrial chain has become a key measure of competitiveness. Zhejiang Jingliang Copper-Tube Products Co., Ltd. is a typical representative of this trend. Founded in 1994, the company has been deeply involved in the copper tube industry for over 30 years, forming a complete industrial chain integrating smelting, extrusion, stretching, precision rolling, and annealing. It is one of the representative comprehensive enterprises in China's copper tube manufacturing field. Its main products cover multiple series including copper tubes, yellow copper tubes, square copper tubes, finned copper tubes, capillary copper tubes, condenser tubes, evaporator tubes, and conductive rods, with complete specifications, stable performance, and product quality that has earned consistent trust and praise from domestic and international customers.

Zhejiang Jingliang Copper-Tube Products Co., Ltd.'s products are widely used in air conditioning and refrigeration, heat exchange, sanitary ware, automotive, machinery, electric furnaces, and chemical industries, fully demonstrating the diversified application value of copper tube materials. Located in Tangpu Town, known as the "Hometown of Copper Tubes" in East China, the company enjoys convenient transportation, adjacent to the Shangsan Expressway and National Highway 104, and approximately 70 kilometers from both Hangzhou and Ningbo. This advantageous location facilitates product transportation and market expansion. The company covers an area of over 20,000 square meters, with a building area of 12,800 square meters. In 2022, its annual output exceeded 7,500 tons, generating a value of approximately RMB 450 million, demonstrating strong production capacity and market competitiveness.

In this new stage of high-quality development in the industry, Zhejiang Jingliang Copper-Tube Products Co., Ltd., relying on its strong financial resources and advanced copper tube processing technology, continues to promote equipment upgrades and intelligent transformation. The company actively implements the "intelligent manufacturing" strategy, integrating factory construction concepts into its corporate development plan, and improving product consistency and efficiency through digital management, automated production, and lean manufacturing systems. With its stable quality, technological innovation, and high-standard customer service, the company has become a long-term partner of many listed groups and has won honors such as "Top Ten Enterprises in the Copper Tube Industry" and "Advanced Taxpayer in the Industry."

Looking to the future, Zhejiang Jingliang Copper-Tube Products Co., Ltd. will continue to uphold the philosophy of "lean manufacturing, quality first, and win-win cooperation," focusing on the research and development of high-end heat exchange copper tubes and environmentally friendly copper alloy products. The company will deepen the construction of an intelligent and green production system and actively respond to the industry's trend of energy conservation and sustainable development. We sincerely welcome customers from home and abroad to visit and guide us, working together to create a bright future for the copper tube industry and striving to become a trusted partner in the global copper tube industry.

English

English Español

Español 中文

中文