The Ultimate Guide to Choosing a Reliable Brass Tube Factory in China

Navigating the World of Brass Tube Manufacturing

In the modern industrial landscape, the brass tube remains an unsung hero. Renowned for its exceptional corrosion resistance, superior thermal conductivity, and ease of machining, brass is the cornerstone of critical components across diverse sectors. From the high-end faucets in luxury bathrooms and the intricate heat exchangers in HVAC and refrigeration systems to high-precision fuel lines in the automotive industry, the demand for high-quality brass tubes is more robust than ever.

However, for global procurement managers and engineers, the sourcing process is often fraught with challenges. The market is flooded with suppliers, but finding a reliable brass tube factory that balances competitive pricing with uncompromising quality and on-time delivery is like finding a needle in a haystack. Common pain points—such as inconsistent alloy compositions, dimensional deviations, and broken lead-time promises—can lead to costly production delays and compromised end-product integrity.

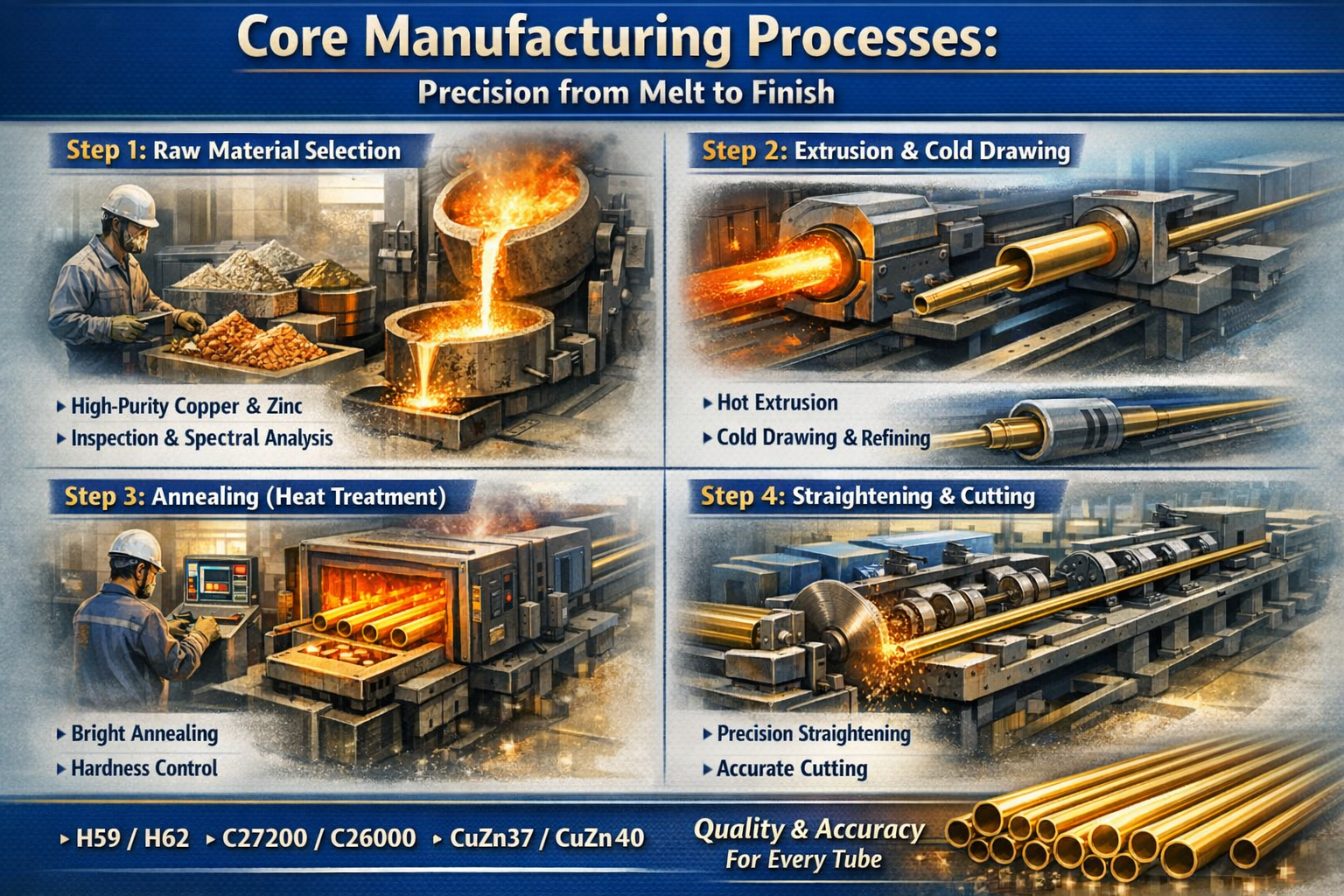

Core Manufacturing Processes: Precision from Melt to Finish

Transparency is the foundation of trust in B2B partnerships. A professional brass tube factory doesn't just "make" tubes; it follows a rigorous, scientifically-controlled sequence to ensure every millimeter of the product meets international standards.

Step 1: High-Purity Raw Material Selection

The quality of a brass tube is determined the moment the furnace is charged. We prioritize high-purity copper and zinc to prevent impurities that cause cracking or premature corrosion.

- Common Grades: We strictly adhere to material specifications such as H59/H62 (Chinese standard), C27200/C26000 (ASTM standard), or CuZn37/CuZn40 (EN standard).

- Composition Control: Every batch undergoes a spectral analysis to ensure the copper-to-zinc ratio is exact, providing the perfect balance of strength and ductility for your specific application.

Step 2: Extrusion & Cold Drawing

This is where the shape takes form.

- Hot Extrusion: The brass billet is heated and forced through a die to create the initial hollow tube. This high-temperature process refines the grain structure of the metal.

- Cold Drawing: To achieve ultra-precise wall thickness and a smooth surface finish, the tube is pulled through a series of precision dies at room temperature. This process is critical for applications in the HVAC and automotive industries, where a deviation of even 0.05mm can lead to assembly failure.

Step 3: Controlled Annealing (Heat Treatment)

Brass becomes "work-hardened" during the drawing process. To meet various client requirements, we use specialized bright annealing furnaces.

- Hardness Customization: By adjusting the temperature and duration, we can deliver tubes in various tempers—from 1/4 Hard for structural rigidity to Dead Soft for applications requiring extreme bending or flaring.

- Atmosphere Control: Our annealing is performed in a controlled atmosphere to prevent oxidation, ensuring the tubes emerge with a bright, clean finish without the need for excessive pickling.

Step 4: Precision Straightening & Cutting

A tube that isn't straight is useless in an automated CNC environment.

- Multi-Roll Straightening: We utilize multi-roll straightening machines to ensure the deviation is kept to a minimum (often less than 0.5mm per meter).

- Tolerance Cutting: Using high-speed circular saws or chipless cutting technology, we provide fixed-length tubes with clean, burr-free ends, ready for immediate use on your production line.

(This image was generated by AI.)

Quality Control Standards: Our Commitment to Zero Defects

In the B2B world, a single defective batch can halt an entire production line or damage a brand’s reputation. That is why a top-tier brass tube factory treats quality control not as a final step, but as a continuous discipline. Our multi-stage QC system ensures that every tube leaving our facility exceeds industry expectations.

Precise Chemical Composition Analysis

The performance of brass—whether it’s the machinability of C36000 or the corrosion resistance of C44300 (Admiralty Brass)—depends entirely on its chemical makeup.

- Spectrometric Testing: We use advanced Optical Emission Spectrometers (OES) to verify the exact percentage of Copper (Cu), Zinc (Zn), and trace elements like Lead (Pb) or Tin (Sn).

- Batch Traceability: Every production run is issued a Material Test Certificate (MTC), allowing for full traceability back to the raw material melt.

Rigorous Mechanical Testing

To ensure the tubes can withstand the pressures of your application, we subject them to intense mechanical stress tests:

- Tensile & Elongation: We verify that the tubes possess the necessary strength and flexibility to be bent or flared without cracking.

- Hardness Testing (Rockwell/Vickers): Ensuring the "temper" matches your specifications—whether you need soft tube for easy manipulation or hard tube for structural integrity.

- Hydrostatic & Eddy Current Testing: For tubes used in fluid transport or heat exchangers, we conduct pressure tests and non-destructive Eddy Current testing to detect hidden internal flaws or leaks.

Superior Surface Inspection

For many of our clients in the sanitary and decorative industries, the surface finish is just as important as the structural integrity.

- Visual & Tactile Audits: Our QC team inspects 100% of the finished products to ensure they are free from sand holes (porosity), scratches, dents, or oxidation marks.

- Roughness Measurement: We use profilometers to ensure the surface smoothness meets the micro-inch requirements for subsequent plating or polishing.

International Certifications & Compliance

We speak the language of global trade. Our factory operates under a strict management framework to meet the world’s most demanding regulatory environments:

- ISO 9001:2015: For consistent quality management systems.

- RoHS & REACH Compliance: Ensuring our brass alloys are safe and environmentally friendly for the European and North American markets.

- CE & ASTM Standards: Aligning our manufacturing tolerances and testing methods with international engineering benchmarks.

Customization Capabilities: Tailored Solutions for Unique Engineering

In today’s competitive market, "one size fits all" rarely applies. A truly versatile brass tube factory must act as a solution provider rather than just a mass producer. Our facility is equipped to handle complex, bespoke requirements that go far beyond standard catalog items.

Versatile Shapes and Dimensional Precision

While the round tube is the industry standard, many architectural and mechanical designs require unique geometries. We offer extensive tooling capabilities to produce:

- Geometric Variety: Precision-engineered square, rectangular, hexagonal, and oval brass tubes.

- Specialized Profiles: Custom "D-shape" or asymmetrical profiles designed for specific interlocking systems or aesthetic hardware.

- Thin-Wall & Heavy-Wall Specialization: Whether you need ultra-thin walls for lightweight decorative items or heavy-duty thickness for high-pressure industrial valves, we maintain tight tolerances across all scales.

Premium Surface Finishes

The "raw" look of brass is only the beginning. Depending on your end-use—be it industrial utility or luxury interior design—we provide professional surface treatments:

- High-Mirror Polishing: Achieving a flawless, reflective surface for high-end furniture and sanitary ware.

- Electroplating (Chrome/Nickel/Gold): Enhancing durability and aesthetics. Our chrome-plated brass tubes are a staple for premium bathroom fixtures.

- Pickling & Passivation: A chemical treatment that removes surface impurities and creates a protective oxide layer, ensuring the tubes remain bright and corrosion-resistant during storage and transit.

- Brushed & Antique Finishes: Custom textures for architectural restoration and decorative lighting.

Comprehensive OEM/ODM Services

We don't just manufacture; we collaborate. Our engineering team provides R&D support to help you move from a concept to a finished product:

- Prototype Development: Rapid sampling for new designs to verify fit and function before full-scale production.

- Alloy Customization: If your project requires a specific lead content for machinability or a particular zinc ratio for color matching, we can develop custom alloy "recipes."

- Technical Consultation: Advice on the best temper and finish for your specific manufacturing environment, helping you reduce scrap rates in your own facility.

Why Partner with a Direct Factory? The Strategic Advantage

In a globalized economy, the shortest distance between your design and a finished product is a direct line to the manufacturer. While trading companies have their place, partnering directly with a brass tube factory offers strategic advantages that significantly impact your bottom line and operational stability.

Cost Efficiency: Elimination of the "Middleman Markup"

Working directly with our factory ensures you receive factory-direct pricing.

- Transparent Pricing: By cutting out wholesalers and secondary distributors, you eliminate the hidden 10%–30% markups often found in the supply chain.

- Bulk Savings: We pass on the economies of scale directly to you. For high-volume annual contracts, this cost reduction can be the difference between winning or losing a major project in your local market.

Stable and Predictable Lead Times

In the world of manufacturing, time is money. When you work with a direct factory, you have a front-row seat to the production schedule.

- Direct Scheduling: We control the production queue. There is no "information lag" caused by a middleman relaying messages. If you have an urgent order, we can adjust our lines internally to accommodate your timeline.

- Real-time Updates: You get accurate, honest status reports directly from the shop floor, allowing your logistics team to plan with 100% confidence.

Direct Technical Support & Problem Solving

When an engineering challenge arises—such as a tube cracking during a specific bending process or a request for a non-standard alloy—you need an expert, not a salesperson.

- Engineer-to-Engineer Communication: You speak directly with our technical team. This ensures that complex requirements aren't "lost in translation."

- Rapid Troubleshooting: Our engineers can perform immediate metallurgical tests or adjustment trials on the production line to resolve issues in days rather than weeks. This level of technical agility is something a third-party vendor simply cannot provide.

Logistics & Packaging: Protecting Your Investment Until It Reaches Your Door

The manufacturing process doesn't end when the tube is cut. For a global brass tube factory, ensuring the product arrives in pristine condition—free from oxidation, dents, or scratches—is just as critical as the production itself. We treat logistics as the final stage of our quality control.

Comprehensive Protection & Anti-Rust Packaging

Brass is sensitive to moisture and sea air during long-distance transit. We offer multi-layered packaging solutions tailored to your shipping method:

- Anti-Oxidation Measures: Each batch can be treated with anti-rust oil or wrapped in VCI (Volatile Corrosion Inhibitor) film and vacuum-sealed to prevent "tarnishing" or "green spots" caused by humid environments.

- Structural Packaging:

- Strong Wooden Crates: For LCL (Less than Container Load) shipments, we use fumigated heat-treated wooden boxes to prevent bending or crushing.

- Woven Bags & Bundling: For FCL (Full Container Load) industrial orders, tubes are securely bundled with reinforced plastic weaving to maximize space while ensuring stability.

- Surface Protection: For high-polish or plated tubes, we provide individual plastic sleeving to ensure zero metal-to-metal contact.

Expertise in Global Shipping & Documentation

Navigating international trade can be complex, but our experienced export team makes it seamless. We handle the "heavy lifting" of logistics:

- Export Clearance: We manage all customs documentation, HS Code classification (typically 7411 for brass tubes), and compliance certificates required for smooth entry into your country.

- Flexible Delivery Terms: Whether you prefer FOB, CIF, or DDP (Delivered Duty Paid), we work with a network of trusted freight forwarders to provide competitive shipping rates by sea, air, or rail.

- Global Reach: With years of experience shipping to North America, Europe, Southeast Asia, and the Middle East, we understand the specific labeling and palletization requirements of different regions.

Product Category

Content

- Navigating the World of Brass Tube Manufacturing

- Core Manufacturing Processes: Precision from Melt to Finish

- Quality Control Standards: Our Commitment to Zero Defects

- Customization Capabilities: Tailored Solutions for Unique Engineering

- Why Partner with a Direct Factory? The Strategic Advantage

- Logistics & Packaging: Protecting Your Investment Until It Reaches Your Door

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文