What Happens Inside a Copper Tube Factory? A Simple Guide to How Copper Pipes Are Made

Introduction – The Hidden Heart of Modern Comfort

When you walk through a modern city or relax in your air-conditioned home, you are surrounded by a silent hero: the copper tube. While they are usually hidden behind walls or inside complex machinery, these red-metal pipes are the "veins and arteries" of our modern world. But have you ever wondered where they come from?

Every high-performance copper pipe begins its journey in a copper tube factory. These facilities are much more than just noisy workshops; they are high-tech hubs where ancient metallurgy meets futuristic engineering. From the water running through your kitchen tap to the coolant keeping your refrigerator icy cold, the products born in a copper tube factory make our comfortable, modern lifestyle possible.

The Manufacturing Process – How a Copper Tube is Born

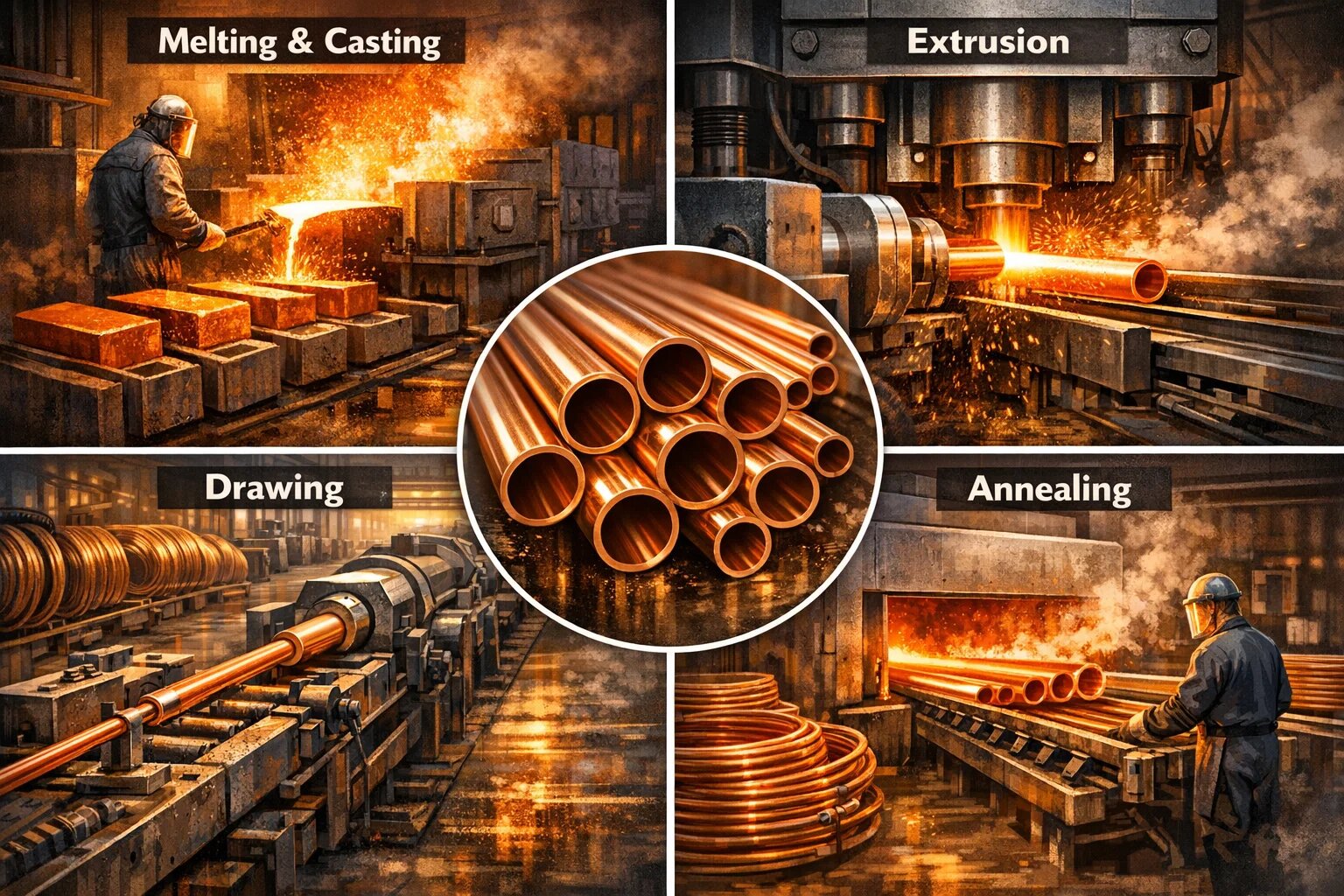

Walking into a copper tube factory feels like entering a world of fire and precision. The process of turning a heavy block of metal into a thin, hollow tube is a feat of engineering. Let’s break it down into four simple steps:

Melting and Casting: The Fiery Start

It all begins with raw copper—often 99.9% pure. In the heart of the copper tube factory, massive furnaces melt this copper at temperatures exceeding 1085°C. Once the metal is liquid, it is cast into solid logs called "billets." Think of these as the giant crayons that will eventually be stretched into miles of tubing.

Extrusion: The Big Squeeze

Now comes the muscle. The factory uses a massive hydraulic press to "squeeze" the heated copper billet through a small hole with a needle in the middle. Imagine squeezing toothpaste out of a tube, but with incredible force. This creates a thick, hollow pipe that is the starting shape of the copper tube.

Drawing: Stretching it Thin

The pipe is still too thick for your home’s plumbing or AC unit. To fix this, the copper tube factory uses a process called "drawing." The tube is pulled through a series of smaller and smaller dies. Each time it passes through, it gets longer, thinner, and stronger.

Annealing: Finding the Perfect Balance

Pulling and stretching the metal makes it hard and brittle. To make the copper flexible again—so a plumber can bend it without it snapping—the factory puts the tubes through an "annealing" oven. By carefully heating and cooling the metal, the factory can decide if the final product will be "hard" (straight pipes) or "soft" (coils that you can bend by hand).

(This image was generated by AI.)

Why Copper? The Superpower of the Red Metal

You might wonder, "Why does a copper tube factory even exist when we have plastic or steel?" The answer lies in copper's natural "superpowers":

- It Kills Germs: Copper is naturally antimicrobial. When used for water pipes, it helps kill bacteria and viruses, keeping your drinking water safer.

- It Handles the Heat: Copper is one of the best conductors of heat on the planet. This is why almost every air conditioner and refrigerator relies on copper tubes to move heat around efficiently.

- It Lasts Forever: Copper doesn't rust like iron or get brittle in the sun like plastic. A copper pipe installed today could easily last 50 to 100 years.

| Feature | Copper Tubes | Plastic (PEX/PVC) | Steel/Iron |

| Durability | Extremely High (50-100 years) | Moderate (25-40 years) | High (but prone to rust) |

| Health & Safety | Naturally Antimicrobial | Possible chemical leaching | Risk of rust/scale |

| Heat Resistance | Excellent (Fireproof) | Melts at high temps | Good |

| Recyclability | 100% Recyclable | Difficult/Limited | 100% Recyclable |

| Best Use Case | High-end plumbing & AC | Budget residential DIY | Industrial heavy-duty |

Quality Control – Ensuring Every Inch is Perfect

In a copper tube factory, there is no room for error. A tiny hole the size of a needle-tip could cause a massive water leak in a skyscraper or ruin a refrigerator. This is why "Quality Control" is the most important department in the building.

Before any tube leaves the copper tube factory, it must pass several "health checks":

- The Pressure Test: High-pressure air or water is pumped into the tubes to make sure they won't burst under stress.

- Eddy Current Testing: This is like an X-ray for metal. The factory uses electricity to scan the tube for hidden cracks or bubbles inside the metal walls that the human eye can't see.

- Cleaning: Especially for air conditioning tubes, the inside must be "clinical grade" clean. Any dust or oil left inside could clog a cooling system, so the factory uses special chemicals and plugs to keep the interior pristine.

A Greener Future – The Recycling Superpower

One of the coolest things about a copper tube factory today is its commitment to the planet. Copper is one of the few materials that can be recycled 100% without losing any quality.

Many modern factories act as "recycling hubs." They take old wires, roof sheets, and used pipes, melt them down, and turn them into brand-new tubes. This uses much less energy than mining new copper from the ground. As the world moves toward electric vehicles and renewable energy (which both need lots of copper), the copper tube factory is becoming a key player in the "Green Revolution."

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文