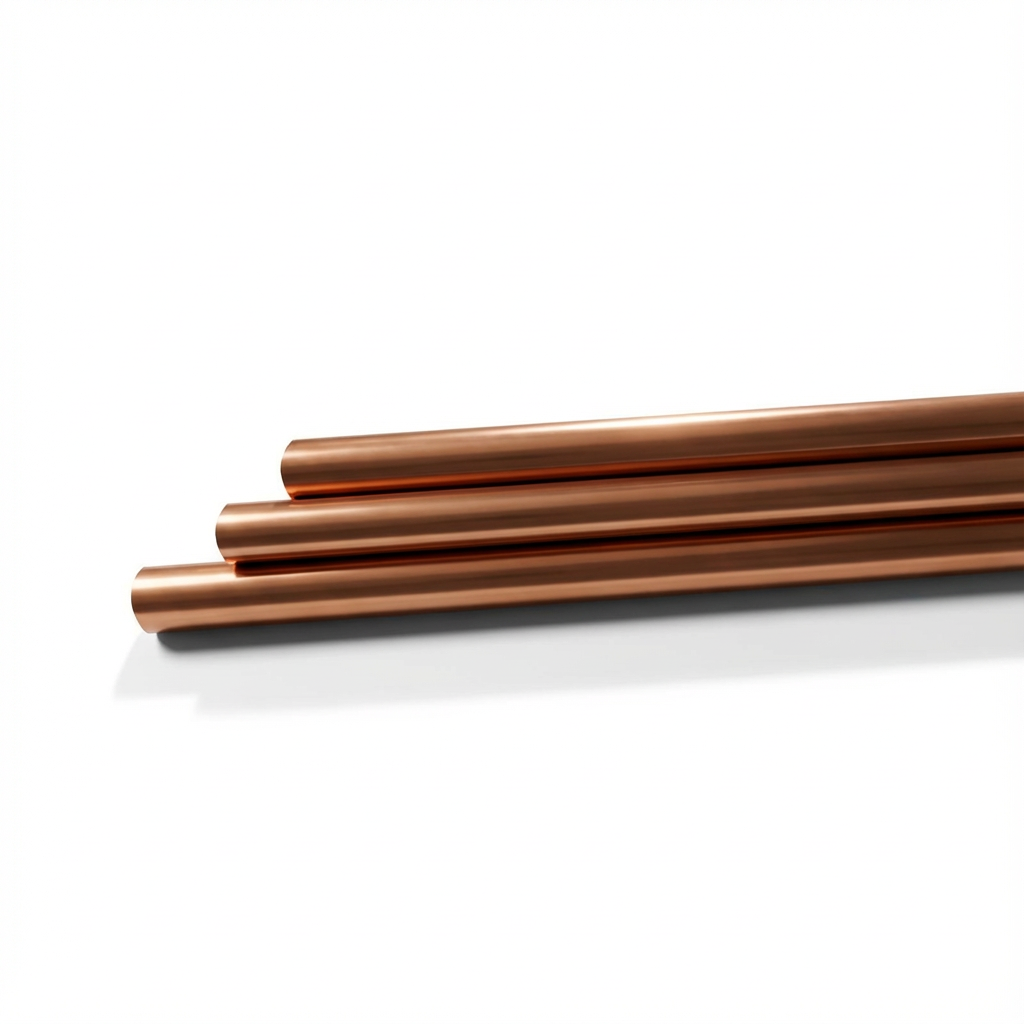

Copper tubes are the "blood vessels" of the refrigeration system, mainly used in condensers, evaporators and connecting pipelines. Its high thermal conductivity (with a thermal conductivity coefficient of approximately 400 W/m·K) enables rapid heat transfer, enhancing the energy efficiency ratio of air conditioners and refrigerators. The promotion of environmentally friendly refrigerants such as R410A has further driven the development of copper tubes towards high pressure resistance, thin-walled and lightweight. Industry standards such as ASTM B280 (Copper Tubes for Air Conditioning) have strict regulations on indicators such as cleanliness and tensile strength to avoid refrigerant leakage and system blockage.

How to ensure the long-term stability of small copper tube with an outer diameter of 5-12mm, especially in high-temperature or corrosive environments?

Small copper tube with an outer diameter of 5-12mm are critical components in many applications, and their long-term stability, especially in high-temperature and corrosive environments, is crucial. To ensure the stability of copper tubes under these harsh conditions, measures need to be taken from multiple aspects, including material selection, surface treatment, design optimization, and regular maintenance.

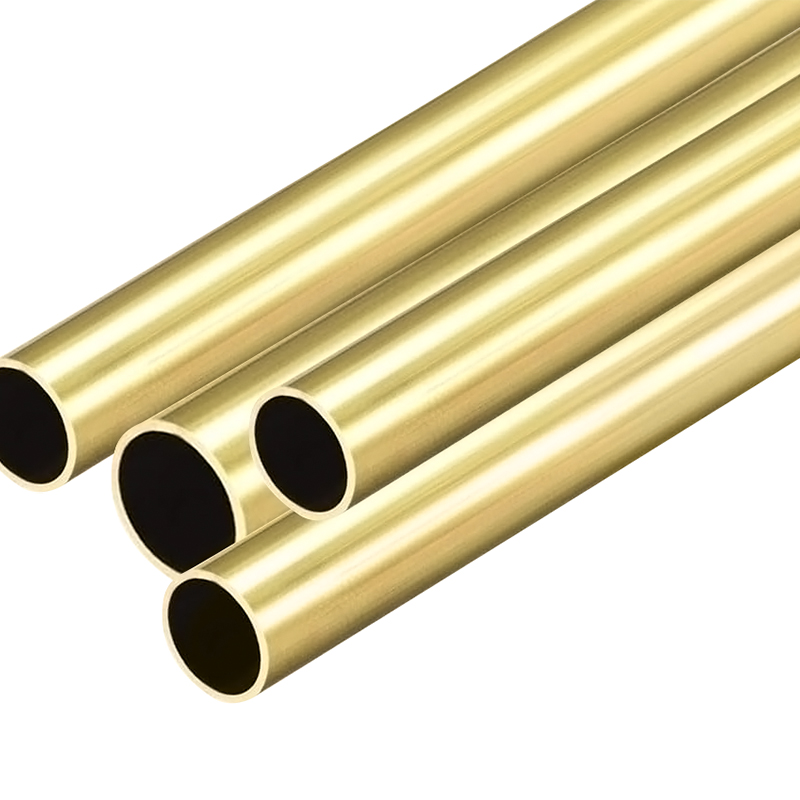

Material selection is the primary factor in improving the stability of copper tubes. Pure copper has good electrical and thermal conductivity, but in high-temperature and corrosive environments, pure copper is susceptible to oxidation, corrosion, and aging. Therefore, many copper tube manufacturers choose copper alloys (such as brass or bronze) to enhance the high-temperature resistance and corrosion resistance of the copper tubes. For example, brass (a copper alloy containing zinc) has good corrosion resistance and is suitable for use in humid or salt spray environments. Bronze (an alloy of copper and tin) has even stronger corrosion resistance, performing particularly well in marine environments or environments with strong chemical corrosiveness.

In high-temperature environments, copper tubes are prone to oxidation, especially when exposed to air for extended periods. To prevent this, the surface of the copper tube can be treated with electroplating, coating, or phosphating to enhance its high-temperature resistance and oxidation resistance. For example, applying a special coating, such as an aluminum or nickel layer, can effectively slow down the oxidation process of the copper tube. In addition, the annealing process during production can also optimize the oxidation resistance of the copper tube by controlling temperature and time.

Surface treatment technologies such as electroplating, oxidation, or coating help improve the stability of copper tubes in corrosive environments. Especially for copper tubes exposed to chemically corrosive environments, nickel plating, zinc plating, or coating techniques are often used. These treatments form a protective film that effectively isolates the copper tube surface from direct contact with the external environment, thus extending the service life of the copper tube.

For copper tubes exposed to corrosive environments, regular maintenance and monitoring are also crucial to ensuring their long-term stability. In some special scenarios, such as marine environments, chemical industries, or urban water supply pipelines, copper pipes need to be regularly inspected for corrosion, cracks, or leaks, and repaired or replaced promptly. Furthermore, using smart sensors to monitor the internal pressure, temperature, and corrosion level of copper pipes can help detect potential risks in advance and allow for timely action.

These measures can effectively improve the long-term stability of small copper tube with an outer diameter of 5-12mm in high-temperature and corrosive environments, ensuring their reliability in various applications.

Small copper tube with an outer diameter of 5-12mm: How to control the uniformity of the tube wall during production?

When producing small copper tubes with an outer diameter of 5-12mm, the uniformity of the tube wall is a critical factor affecting the performance of the copper tube. Especially when copper tubes are used in high-precision applications (such as heat exchangers, refrigeration systems, electronic equipment, etc.), the uniformity of the wall thickness directly affects their thermal conductivity, pressure resistance, and processing performance.

Precise control of precision drawing and cold rolling processes

The production of copper tubes often employs precision drawing and cold rolling processes. Precision drawing is the process of gradually drawing a large-diameter copper tube to a smaller diameter. In this process, the drawing speed, die design, temperature control, and drawing force all need to be precisely calculated and adjusted to ensure the uniformity of the tube wall thickness. Improper parameters in the drawing process can lead to uneven wall thickness and deviations in the inner and outer diameters. Especially in small copper tubes with an outer diameter of 5-12mm, small variations in the drawing process can have a significant impact on wall uniformity.

The cold rolling process changes the size of the copper tube by continuously applying pressure at a lower temperature. During cold rolling, the copper tube undergoes multiple rolling passes, and the rolling pressure, speed, and feeding method of each pass need to be precisely controlled. Especially when producing fine copper tubes, ensuring uniform pressure in each pass and avoiding local deformation is crucial to guaranteeing the uniformity of the tube wall thickness.

Advanced mold design and material quality control

Molds are an important factor in controlling the uniformity of the tube wall. The precision of the mold directly affects the outer diameter and wall thickness of the copper tube. To avoid uneven wall thickness, high-precision molds must be used, and their service life and wear resistance must be ensured. Mold wear also needs to be regularly inspected and maintained during the production process to maintain consistency.

Controlling temperature and pressure during the production process

Temperature and pressure are key factors affecting the uniformity of the copper tube. During drawing and rolling, excessively high or low temperatures can lead to uneven deformation of the copper tube. Especially in the initial stages of the production process, copper tubes have high plasticity. If the temperature is too high, the copper material may experience localized overstretching, leading to uneven wall thickness.

Automated Inspection and Online Monitoring

Modern copper tube production lines are typically equipped with online inspection systems, which can monitor the dimensions, wall thickness, and surface quality of the copper tubes in real time. These automated systems, using high-precision sensors and data analysis technology, can detect uneven wall thickness during the production process and make automatic adjustments, ensuring the consistent quality of each copper tube.

Optimization of the Heat Treatment Process

The heat treatment process, especially annealing, can improve the mechanical properties and plasticity of copper tubes, further ensuring the uniformity of the tube wall. During the annealing process, internal stresses in the copper tube are released, and the wall thickness can be further homogenized, preventing deformation or uneven thickness caused by stress.

Through the above control methods, copper tube manufacturers can ensure that small copper tubes with an outer diameter of 5-12mm have uniform wall thickness, meeting the needs of various high-precision applications.

In the field of mechanical manufacturing, what components are commonly manufactured using small copper tubes with an outer diameter of 5-12mm?

In the field of mechanical manufacturing, small copper tubes with an outer diameter of 5-12mm are widely used in the manufacture of various important components due to their excellent mechanical properties, thermal conductivity, and corrosion resistance. Zhejiang Jingliang Copper-Tube Products Co., Ltd, as a leading company in the industry, with over thirty years of industry experience and advanced technical equipment, produces copper tubes that are widely used in mechanical manufacturing, mainly in heat exchangers, refrigeration systems, hydraulic systems, pneumatic systems, etc., especially in high-precision and high-efficiency equipment.

Heat Exchanger Components

Copper tubes produced by Zhejiang Jingliang Copper-Tube Products Co., Ltd are commonly used in the manufacture of key components in heat exchangers. Heat exchangers are widely used in industrial, construction, air conditioning, and refrigeration fields, and copper tubes, due to their excellent thermal conductivity, are a core material for heat exchangers. Small copper tubes with an outer diameter of 5-12mm are particularly suitable for miniature and precision heat exchangers. Zhejiang Jingliang Copper-Tube Products Co., Ltd precisely controls the outer diameter and wall thickness of the tubes during the production process, ensuring that each copper tube has consistent thermal conductivity and guaranteeing the efficient operation of the heat exchanger. Zhejiang Jingliang Copper-Tube Products Co., Ltd's copper tubes are not only widely used in conventional refrigeration systems but also have important applications in heat exchangers in large industrial equipment.

Condenser and Evaporator Tubes in Refrigeration Equipment and Air Conditioning Systems

In refrigeration equipment and air conditioning systems, small copper tubes with an outer diameter of 5-12mm are widely used in the manufacture of condenser tubes and evaporator tubes. The copper tubes produced by Zhejiang Jingliang Copper-Tube Products Co., Ltd, due to their excellent pressure resistance and thermal conductivity, are suitable for withstanding the circulating pressure of refrigerants and efficiently conducting heat. These copper tubes often serve as refrigerant pipelines in air conditioning and refrigeration systems, performing the functions of gas and liquid conversion and heat exchange. Zhejiang Jingliang Copper-Tube Products Co., Ltd.'s copper tubes undergo meticulous stretching, cold rolling, and annealing processes during manufacturing, ensuring their stability under high pressure and low-temperature environments, making them core components in refrigeration equipment, automotive air conditioning, and household air conditioning systems.

Piping in Automotive Air Conditioning and Cooling Systems

In the automotive industry, especially in automotive air conditioning and cooling systems, the demand for copper tubes is particularly important. Small copper tubes with an outer diameter of 5-12mm are widely used in condenser tubes, evaporator tubes, and coolant circulation pipes in automotive air conditioning systems. Zhejiang Jingliang Copper-Tube Products Co., Ltd. provides copper tube products to automotive manufacturers, which undergo rigorous quality testing to ensure stable operation for extended periods in high-temperature, high-pressure, and corrosive environments. The excellent corrosion resistance and high-pressure resistance of copper tubes have led to their widespread use in automotive air conditioning systems, and Zhejiang Jingliang Copper-Tube Products Co., Ltd. has become a supplier to several well-known automotive brands.

Piping in Hydraulic and Pneumatic Systems

In hydraulic and pneumatic systems, small copper tubes with an outer diameter of 5-12mm serve as hydraulic pipes and pneumatic pipes, responsible for the transportation of liquids and gases. Copper tubes possess strong pressure resistance, corrosion resistance, and excellent sealing properties, ensuring stable fluid transport in hydraulic or pneumatic systems and guaranteeing efficient system operation. Zhejiang Jingliang Copper-Tube Products Co., Ltd.'s copper tube products utilize precise cold rolling processes during manufacturing, resulting in uniform wall thickness and outstanding pressure resistance, meeting the high-pressure transportation requirements of hydraulic systems.

Miniature Piping in Industrial Machinery and Precision Instruments

In some high-precision industrial machinery and precision instruments, small copper tubes with an outer diameter of 5-12mm are used as miniature pipes for liquid transportation, gas transmission, etc. These copper tubes are commonly used in precision manufacturing, especially in applications requiring strict dimensional accuracy and stability. Zhejiang Jingliang Copper-Tube Products Co., Ltd., with its advanced production equipment and strict quality control, provides highly consistent copper tubes to meet customers' high-precision requirements.

Power Transmission in Electrical Equipment

Small copper tubes are also widely used in power transmission systems in electrical equipment. Small copper tubes with an outer diameter of 5-12mm are often used in power transmission lines and internal connecting pipes of electrical equipment due to their excellent conductivity. The copper tubes produced by Zhejiang Jingliang Copper-Tube Products Co., Ltd. not only have excellent conductivity but also high oxidation resistance, enabling long-term stable operation, making them a preferred material in the electrical industry.

Advantages of Zhejiang Jingliang Copper-Tube Products Co., Ltd.

As a reliable partner in the copper tube industry, Zhejiang Jingliang Copper-Tube Products Co., Ltd. possesses unparalleled advantages in the production of small copper tubes with an outer diameter of 5-12mm, thanks to its strong production capacity and complete industrial chain. The company owns a production base of over 20,000 square meters and produces over 7,500 tons of copper tubes annually, demonstrating its large-scale production capabilities. Furthermore, Zhejiang Jingliang Copper-Tube Products Co., Ltd. has a complete industrial chain, including smelting, extrusion, drawing, precision rolling, and annealing technologies, ensuring high quality and precision in every stage of copper tube production.

Zhejiang Jingliang Copper-Tube Products Co., Ltd. also places great emphasis on intelligent manufacturing and lean production, continuously improving production efficiency and ensuring consistency in outer diameter, wall thickness, and precision. In terms of service, Zhejiang Jingliang Copper-Tube Products Co., Ltd. has become the preferred supplier for many domestic and international listed companies, winning the trust and praise of numerous customers with its superior product quality and stable delivery capabilities.

English

English Español

Español 中文

中文