Short-process intelligent manufacturing vs. long-process traditional manufacturing: A production efficiency revolution for copper tubes in 2025?

In 2025, the competitive focus of the copper tube industry shifted from the "market side" to the "production side," with a comprehensive battle unfolding around process innovation and optimization. On one side, "short-process intelligent manufacturing" is rising strongly by eliminating redundancy, improving efficiency, and reducing energy consumption, reshaping the industry's cost and environmental advantages through digitalization and integrated production. On the other side, "long-process traditional manufacturing" maintains its position with its "mature and stable, widely applicable" characteristics, retaining its irreplaceable role in complex specifications and mass production. This technological showdown between "streamlined intelligence" and "traditional stability" is rewriting the core rules of copper tube production.

Comparison of Core Processes and Production Flows: Smart and Streamlined Approach vs. Traditional and Robust Approach

| Comparison Dimension | Short-Process Intelligent Manufacturing | Long-Process Traditional Manufacturing | Data Source |

| Core Production Process | Horizontal continuous casting of hollow ingots → cold rolling and blanking → drawing → intelligent inspection → finished product (no extrusion process) | Semi-continuous casting → hot extrusion → cold rolling → multi-pass drawing → manual inspection → finished product | China Nonferrous Metals Industry Association 2025 Process Report |

| Production Cycle | Single batch finished product time ≤ 4 hours | Single batch finished product time ≥ 12 hours | JinXin Copper Tube / Southwest Copper Industry actual measurement data |

| Unit Product Energy Consumption | ≤ 350 kWh/ton (electricity saving of over 600 kWh/ton) | ≥ 950 kWh/ton | Ministry of Industry and Information Technology Industrial Energy Saving Monitoring Platform 2025 |

| Comprehensive Yield | 88%-93% (increase of 10%-15%) | 75%-80% | Scientific and Technological Achievement Appraisal Report (2025) |

| Carbon Emissions | ≤ 1.2 tons CO₂/ton | ≥ 2.8 tons CO₂/ton | Carbon Footprint Accounting Platform actual measurement |

| Core Technology Support | Ultrasonic-assisted casting, intelligent straightening and sawing robot, full-process digital system | Hot extrusion molding, manual mold debugging, segmented quality control | Enterprise Technology White Paper / Production Site Survey |

| Equipment Investment Cost | Approximately 80 million RMB per production line (automation rate ≥ 90%) | Approximately 45 million RMB per production line (automation rate ≤ 60%) | Jinchuan Group / Jinlong Group procurement data |

| Applicable Product Types | Precision alloy tubes, ultra-thin wall tubes, high-purity oxygen-free copper tubes | General-purpose copper tubes, large-diameter thick-walled tubes, conventional alloy tubes | Market Order Structure Analysis 2025 H1 |

| Environmental Protection Indicators | 60% reduction in exhaust emissions, no pickling wastewater (low-concentration pickling technology) | Pickling wastewater treatment volume ≥ 5 tons/ton of product, higher exhaust emissions | Ministry of Ecology and Environment Pollution Discharge Permit Monitoring Data |

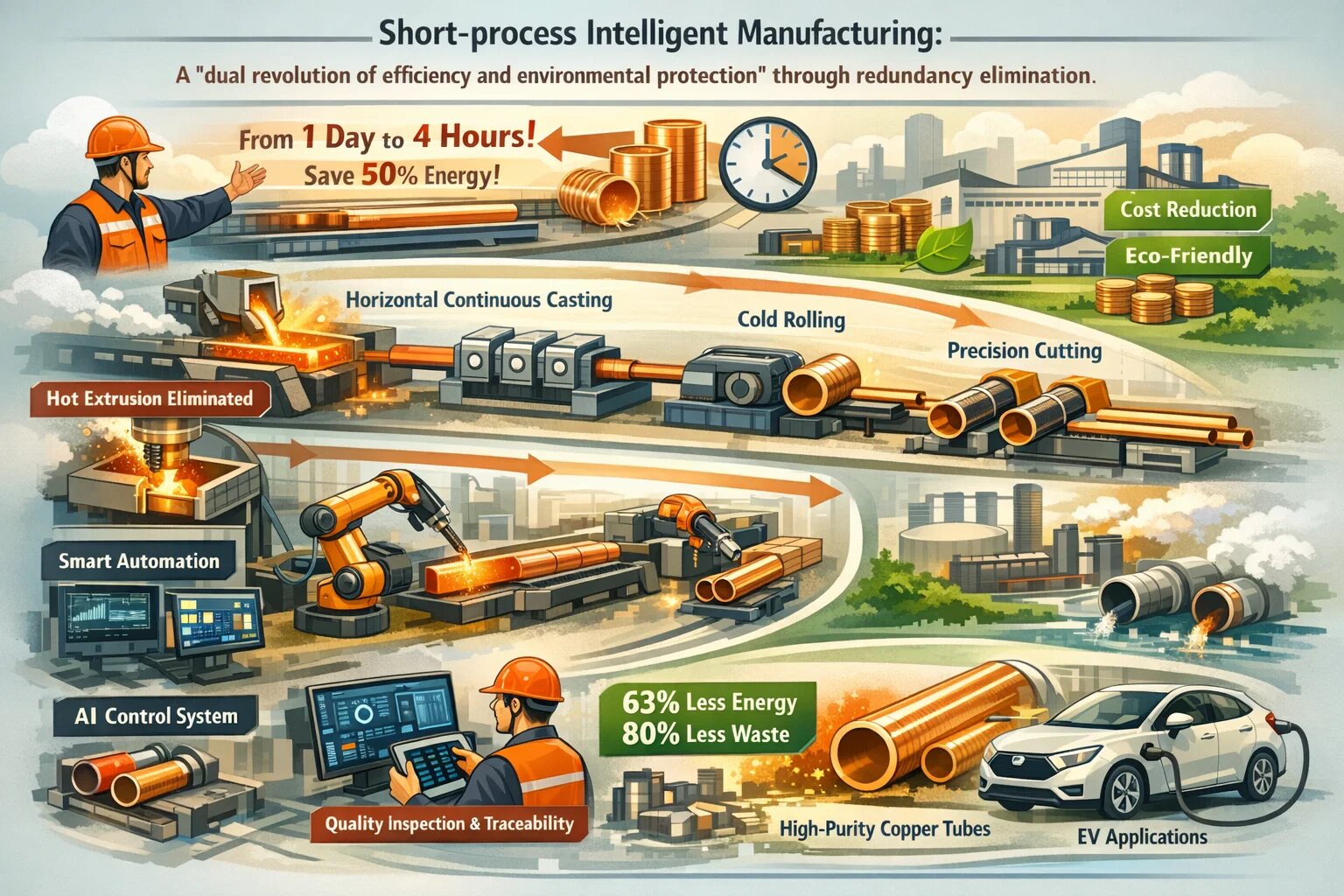

Short-process intelligent manufacturing: A "dual revolution of efficiency and environmental protection" through redundancy elimination.

“Previously, it took a whole day to produce a batch of precision copper tubes, but now we can ship them in just 4 hours, and we save half the electricity!” said the head of the JinXin Copper Tube workshop in Taicang, Jiangsu, pointing to the fully automated production line. In 2025, the "short-process production technology for copper alloy tubes," jointly developed by the company and Central South University, passed national-level certification. This extrusion-free process of "horizontal continuous casting of hollow ingots - cold rolling - drawing" completely revolutionized traditional production methods.

The core breakthroughs lie in "process simplification" and "intelligent empowerment." The traditional "hot extrusion" step is directly eliminated, and ultrasonic-assisted casting technology is used to optimize the crystal structure of the tube blank, reducing metal segregation and resulting in an inner surface roughness of ≤0.8μm, allowing it to proceed directly to the cold rolling process without subsequent polishing. In Southwest Copper's "hot-state three-furnace" short-process production line, the integrated configuration of "oxygen-enriched side-blown smelting + multi-lance top-blown continuous refining + rotary anode furnace refining" achieves continuous production from copper concentrate to anode copper, with an annual processing capacity of 1.6 million tons. This reduces three transfer steps compared to traditional processes and compresses the equipment footprint by 40%.

Intelligent equipment has become a multiplier of efficiency. Jinchuan Group's Precision Copper Materials Company invested in a fully automated straightening and sawing robot, reducing the number of workers on a single production line from 3 to 1, and increasing daily output from 30 pieces to 80 pieces. The flatness error of the cut surface is ≤0.02mm, far exceeding the 0.1mm standard of manual operation. The fully digital system realizes a closed loop of "production - inspection - traceability": Xinjiang Wuxin Copper Industry's intelligent transfer carts and automatic labeling system record the weight, composition, and processing parameters of each batch of copper tubes in real time into a database, achieving a 100% accuracy rate for product traceability, and reducing the time to trace quality problems from 2 hours to 10 minutes.

Environmental protection and cost advantages are evident. The short-process technology eliminates the high-temperature heating process of hot extrusion, saving over 600 kilowatt-hours of electricity per ton of copper tube, and reducing overall energy consumption by 63%. Low-concentration acid pickling technology replaces traditional strong acid cleaning, reducing wastewater discharge by 80% and exhaust gas emissions by 60%. According to data from Jinxin Copper Tube, this process reduces production costs by 1200-1500 yuan per ton. For high-end products such as ultra-thin-walled copper tubes for new energy vehicles and high-purity copper tubes for medical use, the gross profit margin is increased by 8-10 percentage points compared to traditional processes.

(This image was generated by AI.)

Long-process traditional manufacturing: A reliable and versatile "broad-spectrum adapter"

Despite the rapid rise of short-process technologies, traditional long-process methods still hold a significant share of the industry. "Not all copper tubes are suitable for short-process manufacturing. For example, large-diameter, thick-walled tubes with diameters exceeding 50mm require the hot extrusion process to ensure dense metal structure, something that short-process methods cannot currently replicate," explained a production manager at Jinlong Group. As the world's largest manufacturer of precision copper tubes, Jinlong Group still maintains 12 long-process production lines, primarily serving applications with extremely high structural strength requirements, such as embedded pipes in buildings and condenser tubes for marine vessels.

The core competitive advantage of the long-process manufacturing method lies in its "maturity and stability" and "broad applicability." Its process of "semi-continuous casting – hot extrusion – cold rolling – multi-pass drawing," refined over decades of iterative optimization, can handle various copper alloy materials such as H62, H65, and HA177-2. The product specifications cover diameters from Φ6mm to Φ219mm and wall thicknesses from 0.5mm to 10mm, adapting to a wide range of applications from ordinary water supply and drainage to heavy industrial use. When mass-producing general-purpose copper tubes, the long-process method has lower equipment depreciation costs, and a single production line can achieve an annual capacity of 15,000 tons, 25% higher than shorter-process production lines.

Technological upgrades extend the product lifecycle. Traditional processes have not stagnated but have enhanced their competitiveness through "localized intelligent transformation": Jinlong Group introduced an AI mold temperature control system in the hot extrusion process, reducing mold wear rate by 30% and improving the tooth profile accuracy of Inner Grooved Tubes from ±0.05mm to ±0.03mm; some companies have adopted a "oxygen-enriched combustion + waste heat recovery" system, reducing energy consumption per unit of product from 1050 kWh/ton to 950 kWh/ton, and reducing carbon emissions by 22%, thus narrowing the environmental gap with short-process manufacturing to some extent.

It remains irreplaceable in specific fields. Products such as extra-large diameter copper-nickel alloy seamless pipes for marine vessels and condenser tubes for nuclear power plants require the pipes to have a service life of at least 30 years in high-pressure and corrosive environments. The long-process hot extrusion technology refines the metal grains and increases the yield strength by more than 20%. Currently, the stability of similar products produced by short-process technology in extreme environments still needs time to be verified. Data from 2025 shows that the long-process technology still holds a 78% market share in the large-diameter copper tube (Φ≥50mm) market, and maintains a market share of over 65% in traditional manufacturing sectors.

Process Integration: A Core Trend in Manufacturing by 2025

In the copper tube industry of 2025, short-process and long-process manufacturing are not mutually exclusive, but rather form an integrated ecosystem of complementary advantages. Leading companies are beginning to explore "hybrid processes": using short-process horizontal continuous casting technology in the initial stages to improve billet quality, while retaining the hot extrusion process in the later stages to accommodate special specifications; or embedding short-process technology modules such as intelligent detection and automated transfer into long-process production lines to achieve "robust foundation + efficiency upgrade."

Market segmentation is becoming clearer: short-process intelligent manufacturing focuses on high-end precision and small-to-medium diameter products, such as copper tubes for thermal management in new energy vehicles, medical antibacterial copper tubes, and semiconductor cooling tubes, with an expected penetration rate exceeding 40% by 2026; long-process traditional manufacturing maintains its dominance in general-purpose, large-diameter, and extreme-environment products, in sectors such as construction, marine, and nuclear industries. At the policy level, the Ministry of Industry and Information Technology has included "short-process intelligent transformation of copper tube manufacturing" in the "2025 Industrial Green Manufacturing Promotion Plan," providing subsidies of up to 5 million yuan to companies undergoing transformation, accelerating technological upgrades.

The core of future competition will be "process adaptability": companies will need to select core processes based on product positioning, while simultaneously addressing shortcomings through digital and green technology upgrades. Short-process technologies need to overcome bottlenecks in the production of large-diameter, thick-walled pipes, while long-process technologies require continuous reductions in energy consumption and environmental costs. This revolution in production processes will ultimately drive the copper tube industry from "scale competition" to "refined competition based on precision and efficiency," forming a dual production structure of "high-end intelligent + general robust" manufacturing.

Product Category

Content

- Comparison of Core Processes and Production Flows: Smart and Streamlined Approach vs. Traditional and Robust Approach

- Short-process intelligent manufacturing: A "dual revolution of efficiency and environmental protection" through redundancy elimination.

- Long-process traditional manufacturing: A reliable and versatile "broad-spectrum adapter"

- Process Integration: A Core Trend in Manufacturing by 2025

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文