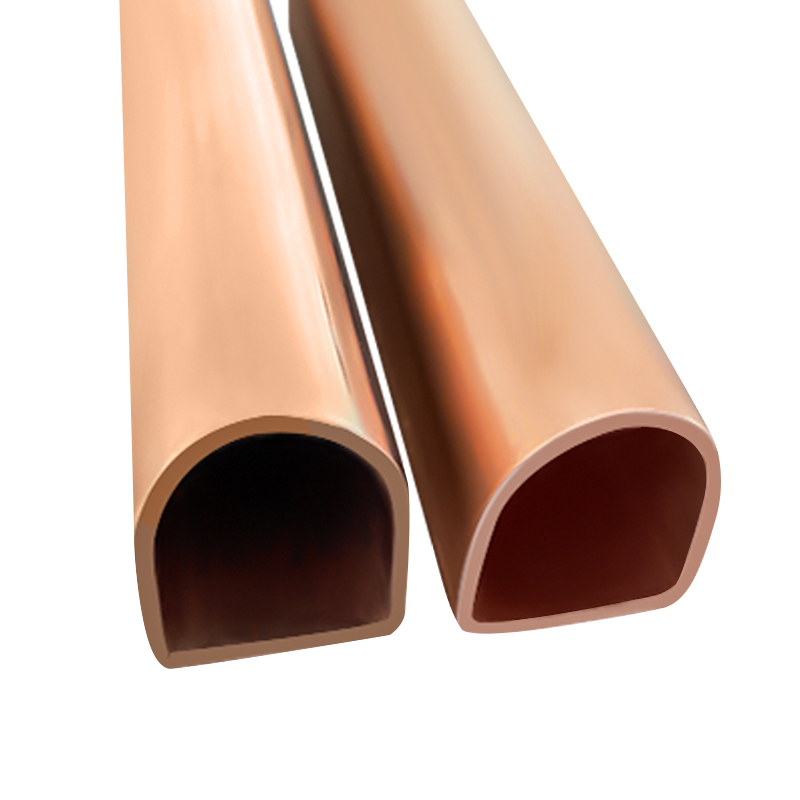

Special-shaped copper tube refers to all copper tubes with cross sections other than circular, including hexagonal, semi-elliptical, octagonal, etc., which are made of high-purity copper or copper alloy materials through precision cold extrusion with multi-stage dies. Our company has professional mold development and manufacturing capabilities, and can customize special-shaped copper tubes of various shapes and specifications according to the drawings or samples provided by customers. The product has a variety of structural shapes, which can effectively improve space utilization and component stability; at the same time, it has good weldability and processability. It is widely used in industries such as architectural decoration, art components, electronic and electrical structures, automotive and aviation parts, medical equipment, and high-end home hardware. It is an ideal material for realizing customized needs in functional and aesthetic design.

ABOUT US

30+YEARS OF

EXPERIENCE

About Us

A Reliable Partner of the Copper Tube Industry

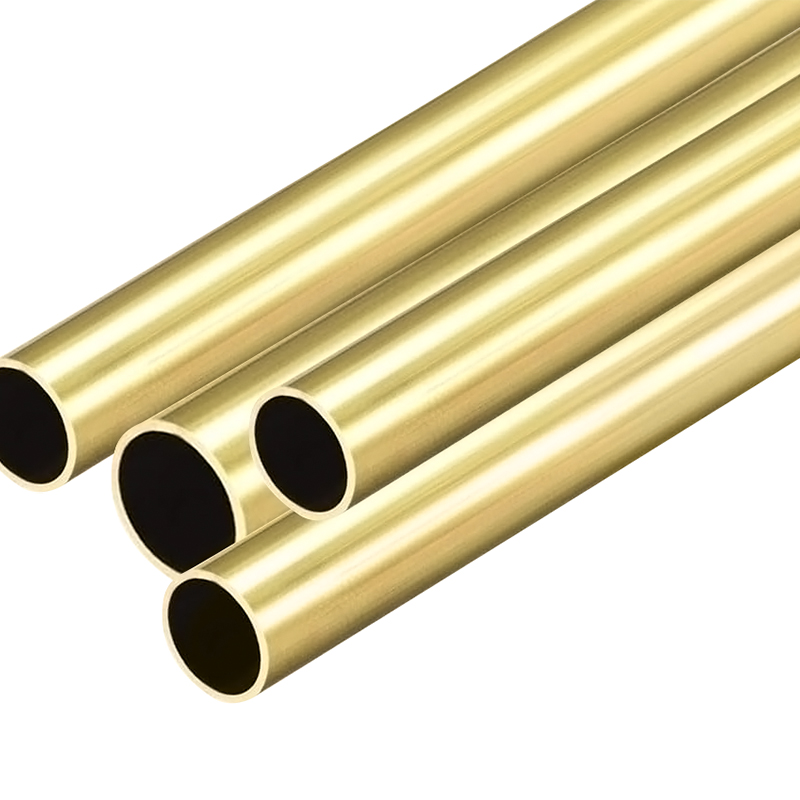

Zhejiang Jingliang Copper-Tube Products Co., Ltd established in 1994, is China Special Shaped Copper Tube Manufacturers and Custom Special Shaped Copper Tube Suppliers, has been deeply involved in the copper tube industry for over three decades. The company primarily produce various specifications of products such as copper tubes, brass tubes, copper square tubes, fin copper tubes, copper capillary tubes, condenser copper tubes, copper evaporator tubes, and conductive rods, which are of quality and have earned the trust and acclaim of customers both domestically and internationally.

Wide Applications:

These products are widely used in various fields including air conditioning, refrigeration, heat exchange, sanitary ware, automotive, machinery, electric furnaces, and chemical industries.

Convenient Transportation:

Strategically located in Tangpu Town, renowned as the “home of copper tubes” in East China. Our company enjoys a prime location, adjacent to the Shangsan Expressway and National Highway 104, and is conveniently situated just over 70 kilometers from Hangzhou and Ningbo, ensuring easy accessibility and a business position.

Strong Financial Resources:

With its strong financial resources and advanced copper tube processing technology, our company holds an advantageous position in market share, brand value, technological content, and product quality, becoming a preferred supplier for many listed groups.

Large Scale Production:

The company occupies an area of over 20,000 square meters, with a construction area of 12,800 square meters. In 2022, our annual production exceeded 7,500 tons, with a value output of up to 450 million yuan, demonstrating our strong production capacity and market competitiveness.

Comprehensive Industry Chain:

Jingliang has now developed into a complete industrial chain integrating smelting, extrusion, drawing, precision rolling, and annealing. It has been awarded multiple honors, including "Top Ten Copper Tube Enterprises" and "Leading Taxpayer in the Copper Tube Industry".

Smart Manufacturing:

Jingliang Copper-Tube Products will better integrate the concept of factory construction into its corporate development strategy, insist on refining technology and polishing products more finely, and the future of "intelligent manufacturing".

Genuine Cooperation:

Zhejiang Jingliang Copper-Tube Products Co.,Ltd warmly welcomes friends from all walks of life to visit and offer guidance. We look forward to joining hands with you to create a brilliant future together.

Technical skills

Production Process

- 1、Electrolytic Copper

- 2、Copper Ingots

- 3、Press

- 4、Drawing

- 5、Rolling

- 6、Packaging

Electrolytic copper, produced through electrolytic processes, is a high-purity copper with good electrical conductivity and thermal conductivity, making it an ideal material for manufacturing copper pipes.

This marks the beginning of our production process, which involves the fabrication of electrolytic copper into pure copper or brass ingots according to specific requirements, followed by cutting to facilitate subsequent processing and handling.

In the pressing stage, the cut copper ingots are pressed into thin sheets or tubular shapes, forming the initial tube shape, and the copper ingots are prepared for drawing and rolling.

Drawing is the process of further processing the copper sheets or tubular objects that have been pressed into the required dimensions and shapes. Through drawing, our copper tubes can achieve precise outer diameters and wall thicknesses.

Rolling is the step of further processing the copper tubes after drawing. Through rolling, the copper tubes are rolled into more precise dimensions and shapes to meet the requirements of different applications.

Finally, the copper tubes that have undergone rolling will be packaged and prepared for shipping. We ensure that the packaging is safe and protective to prevent damage during transportation.

News

-

Introduction: The Heart of Modern Thermal Management In an era where energy efficiency is no longer a luxury but a global mandate, the demand for high-performance thermal components has reached an all-time high. Under the mounting pressure ...

READ MORE -

Despite a challenging global market environment, Zhejiang Jingliang Copper-Tube Products Co., Ltd. recently held its Annual Summary Conference to review the past year’s achievements and outline strategies for the year ahead. The meeting bro...

READ MORE -

Navigating the World of Brass Tube Manufacturing In the modern industrial landscape, the brass tube remains an unsung hero. Renowned for its exceptional corrosion resistance, superior thermal conductivity, and ease of machining, brass is th...

READ MORE

Industry knowledge

How to control the uniformity of wall thickness when producing special-shaped copper tubes

Technical difficulties in wall thickness uniformity

Special-shaped copper tubes are different from traditional round copper tubes. Their cross-sectional shapes may be elliptical, D-shaped, flat, petal-shaped, etc. These asymmetric or multi-curved shapes are prone to uneven metal flow during extrusion or drawing, which in turn leads to inconsistent tube wall thickness, affecting the structural strength, thermal conductivity and connection reliability in subsequent applications. Therefore, controlling the uniformity of wall thickness is not only a challenge for manufacturing technology, but also the core guarantee of product quality.

Technical practice of Zhejiang Jingliang in wall thickness control

1. Complete industrial chain support to ensure the consistency of basic materials

Zhejiang Jingliang has a complete industrial chain from copper ingot smelting to extrusion, drawing, finishing rolling and annealing. The uniformity of raw material composition is the first step to ensure wall thickness consistency. Through independent smelting technology, the company can accurately control the alloy ratio and purity, ensure that the original billet has good plasticity and consistent fluidity in the subsequent forming process, and lay the foundation for wall thickness consistency.

2. High-precision mold system design

The mold design of special-shaped copper tubes directly determines the metal flow direction and pressure distribution during the forming process. Zhejiang Jingliang uses CAE simulation software to optimize the mold structure, and combined with long-term accumulated experience data, it has developed a variety of precision mold systems suitable for complex special-shaped sections. In the mold processing process, CNC machining centers (CNC) and EDM technology are introduced to further improve the surface accuracy and consistency of the mold, and improve the wall thickness stability from the root.

3. Multi-pass precision drawing process

In order to achieve high-precision control of complex cross-sections, Zhejiang Jingliang adopts a multi-pass cold drawing process. In each drawing process, strict deformation rate control parameters are set to ensure that the flow rate of the copper material is uniform during the deformation process, and to avoid the problem of "thin wall" at the corner or edge of the cross-section due to excessive metal flow. After each process, online wall thickness detection is required to achieve "find one place, correct one place".

4. Annealing and stress release control

Copper tubes will accumulate residual stress during the forming process. If not handled properly, rebound or wall thickness variation will occur during storage, transportation or use. Zhejiang Jingliang uses a multi-stage annealing furnace to set temperature partitions and annealing curves according to the shape and alloy type of the copper tube to release stress to the greatest extent, restore the plasticity of the material, and maintain the stability of the wall thickness structure.

How to detect the internal stress or residual stress of special-shaped copper tubes

The source and harm of residual stress

The residual stress mainly comes from the uneven metal flow during the hot processing (such as extrusion, annealing), cold processing (such as drawing, rolling) and complex mold forming of special-shaped copper tubes. Especially in special-shaped tubes with large cross-sectional curvature and inconsistent thickness, the metal is prone to form tensile stress at the edge and compressive stress at the core during plastic deformation, leaving invisible but highly destructive "stress hazards" in the finished product.

The potential risks brought by residual stress include:

Cracking, rebound, and bending deformation in subsequent processing;

Stress corrosion cracking (SCC) during use;

Stress mismatch between multiple welded tubes leads to welding defects;

Thermal conductivity or mechanical properties are reduced.

Therefore, how to scientifically and accurately detect the residual stress of special-shaped copper tubes has become one of the key indicators of quality control for high-end copper processing companies.

Zhejiang Jingliang's technical path in stress detection

As an enterprise with a complete industrial chain and high-end testing equipment, Zhejiang Jingliang Copper-Tube Products Co., Ltd has formed a multi-method combined and multi-level controlled detection system for residual stress detection. The following are several methods commonly used by the company in actual production:

1. X-ray diffraction (XRD)

X-ray diffraction is one of the most commonly used and most accurate methods for detecting metal surface stress. The XRD system introduced by Zhejiang Jingliang can measure the residual stress of the surface layer at the microscopic crystal level, and is particularly suitable for detecting stress concentration areas such as the edges, corners, and bending points of the cross-section of special-shaped copper tubes. This technology has the following characteristics:

Non-destructive;

High resolution (accurate to ±5 MPa);

Can vector decompose stress in different directions.

2. Strain Gauge Method

In order to detect the stress release of copper tubes under simulated use conditions, the company uses strain gauges for auxiliary detection in a laboratory environment. By sticking strain gauges on the surface of special-shaped copper tubes, recording small deformations during heating or bending, the degree of stress release can be inferred. This method is suitable for monitoring the evolution of stress throughout the entire process and is extremely valuable for new product development.

3. Slitting or Ring-Core Method

When it is necessary to detect the deep stress distribution inside the copper tube, Zhejiang Jingliang uses a local cutting method (such as the ring grooving method) for stress release measurement. By making a small area cut at a specific part of the special-shaped copper tube and using a laser displacement meter or a high-precision strain gauge to observe the micro-deformation data after release, the original stress value can be inferred. Although this type of method is a semi-destructive test, it plays an important role in structural optimization and mold design verification.

4. Digital Image Correlation (DIC)

As an important part of intelligent manufacturing, Zhejiang Jingliang also introduced digital image correlation technology (Digital Image Correlation) in stress detection. This technology can record the microscopic deformation image of the copper tube surface under stress state through a high-resolution camera, and reconstruct the stress field in combination with an algorithm. It is particularly suitable for non-contact stress evaluation of special-shaped copper tubes with complex cross-sections.

How to improve the oxidation resistance and life of special-shaped copper tubes in actual use

The mechanism and impact of copper tube oxidation

Copper reacts with oxygen, carbon dioxide, water vapor and other substances in the air to form a copper oxide film. Although this oxide film has a certain protective effect, in an environment with high temperature or corrosive media, the oxide film will further oxidize or peel off, resulting in increased corrosion on the copper surface and decreased performance. Due to the complex cross-sectional shape of special-shaped copper tubes, some areas are prone to stress concentration or local microenvironment, and the risk of oxidation corrosion is higher, thus affecting the structural integrity and heat exchange efficiency of the tube.

Zhejiang Jingliang's technical practice in improving the oxidation resistance of special-shaped copper tubes

1. Optimizing material selection and alloy composition

Zhejiang Jingliang has the ability to control the entire industrial chain from smelting, extrusion, drawing to annealing. Through independent smelting technology, it accurately controls the composition of copper alloys and introduces appropriate amounts of antioxidant elements (such as phosphorus, zinc, etc.), which significantly improves the corrosion resistance of copper. At the same time, the company customizes special copper alloys according to the customer's application environment to ensure that special-shaped copper tubes perform well in high temperature and corrosive media.

2. Refined heat treatment process

Heat treatment is an important part of improving the anti-oxidation performance of copper tubes. Zhejiang Jingliang adopts advanced multi-stage annealing technology, strictly controls temperature and holding time, optimizes the grain structure of copper materials, reduces internal defects and stress concentration of materials, thereby enhancing the stability and adhesion of oxide film, and effectively extending the anti-oxidation life of copper tubes.

3. Surface treatment and protective coating technology

In response to the needs of special-shaped copper tubes exposed to harsh environments, Zhejiang Jingliang has launched a variety of surface protection technologies:

Physical vapor deposition (PVD) coating: forms a dense and uniform protective film to improve corrosion resistance and wear resistance;

Organic coating: covers the surface of copper tubes by spraying or dipping, isolates air and moisture, and prevents oxidation reactions;

Electrochemical plating: such as nickel plating, tin plating, etc., increases the anti-oxidation and conductivity of copper tubes, especially suitable for electronics and automotive fields.

4. Intelligent manufacturing and online quality monitoring

Zhejiang Jingliang actively promotes intelligent manufacturing, combines online non-destructive testing technology to monitor the surface quality and oxide film thickness of copper tubes in real time, ensures that there are no scratches and pollution on the surface of copper tubes in the production process, reduces oxidation defects from the source, and ensures that the product has an excellent anti-oxidation foundation when it leaves the factory.

Maintenance and life extension strategies in actual use

1. Reasonable design and installation environment optimization

Reasonable design can reduce local stress concentration and water accumulation, and reduce the generation of corrosion points. Zhejiang Jingliang provides customers with professional design support and recommends avoiding direct contact between special-shaped copper tubes and highly corrosive media during equipment installation, and at the same time, cooperate with good sealing and drainage design to effectively delay the oxidation process.

2. Regular cleaning and protective maintenance

Regularly remove dust, salt and organic matter from the surface of copper tubes to prevent these substances from becoming corrosion catalysts. At the same time, combined with appropriate protective agent spraying, a secondary protective layer can be formed to improve the anti-oxidation ability and overall life of the copper tube.

3. Monitoring environmental parameters

Use sensors to monitor the humidity, temperature and corrosive gas concentration of the equipment operating environment, and adjust the operating parameters or take protective measures in time. In the future, Zhejiang Jingliang will promote the research and development and application of the copper tube full life cycle environmental monitoring system under the framework of intelligent manufacturing to further improve the safety and reliability of products.

English

English Español

Español 中文

中文