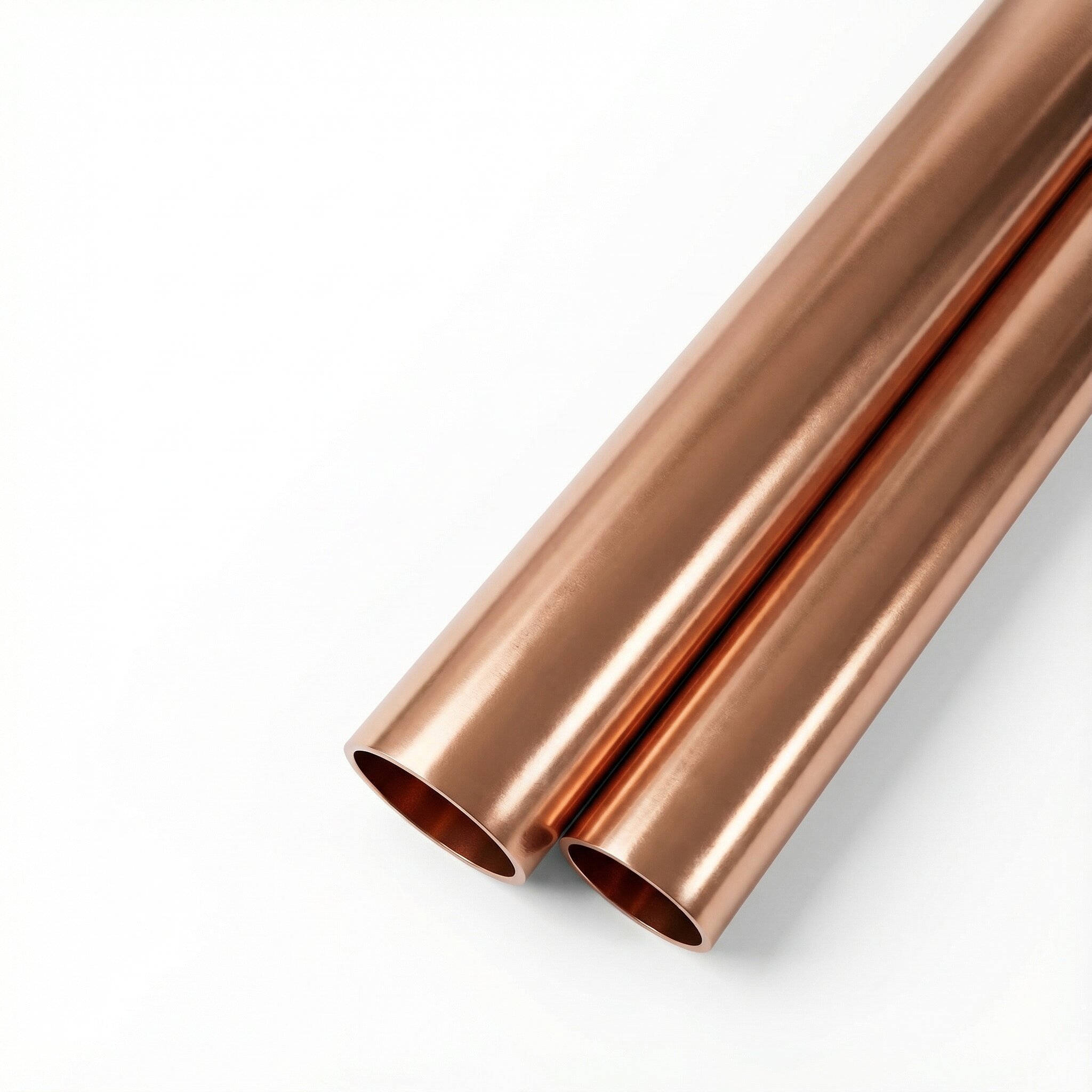

Copper tubes are the "blood vessels" of the refrigeration system, mainly used in condensers, evaporators and connecting pipelines. Its high thermal conductivity (with a thermal conductivity coefficient of approximately 400 W/m·K) enables rapid heat transfer, enhancing the energy efficiency ratio of air conditioners and refrigerators. The promotion of environmentally friendly refrigerants such as R410A has further driven the development of copper tubes towards high pressure resistance, thin-walled and lightweight. Industry standards such as ASTM B280 (Copper Tubes for Air Conditioning) have strict regulations on indicators such as cleanliness and tensile strength to avoid refrigerant leakage and system blockage.

What are the main application areas of large copper tubes with an outer diameter of 28-54mm?

Large copper tubes with an outer diameter of 28-54mm, due to their larger outer diameter and wall thickness, are typically used in applications requiring high strength, pressure resistance, and good thermal conductivity. Because copper itself has good thermal conductivity and corrosion resistance, and can withstand large mechanical loads, these tubes have a wide range of applications in various industries.

Air Conditioning and Refrigeration Industry

Large copper tubes with an outer diameter of 28-54mm are widely used in the air conditioning and refrigeration industry, especially in large air conditioning systems and industrial refrigeration equipment. Due to their larger outer diameter, these tubes can withstand higher pressures and effectively transfer heat, thus playing an important role in condensers, evaporators, and coolers. In these systems, they are typically used for refrigerant transport and heat exchange. The superior thermal conductivity of these tubes allows for more efficient heat exchange, thereby improving system efficiency, reducing energy consumption, and maintaining long-term stable operation of the equipment.

Heat Exchangers

Heat exchangers are used in various industries, such as chemical, power, and metallurgy, which have extremely high requirements for heat exchange efficiency. Due to their excellent thermal conductivity, large copper tubes with an outer diameter of 28-54mm are often used in various heat exchangers, especially in systems requiring rapid heat exchange. They are widely used in condensers and evaporators in the petrochemical industry. Due to the good thermal conductivity of copper, these tubes can provide a larger heat transfer area, improve heat exchange efficiency, and adapt to high-temperature and high-pressure working environments.

Oil and Natural Gas Transportation

In the oil and natural gas industry, the corrosion resistance and strength of large copper tubes with an outer diameter of 28-54mm make them an ideal material for liquid and gas transportation systems. Especially in natural gas pipelines, copper pipes can withstand high pressure and harsh environmental conditions, preventing corrosion and leakage. The corrosion resistance of large copper tubes with an outer diameter of 28-54mm is one of their important advantages in applications such as transporting chemicals and petroleum, as they effectively resist corrosion caused by salts, acids, alkalis, and other corrosive factors in liquids.

Chemical Industry

In the chemical industry, especially in equipment requiring high temperature and corrosion resistance, such as reactors and distillation columns, large copper tubes with an outer diameter of 28-54mm are widely used. Due to their corrosion and oxidation resistance, copper pipes can effectively prevent corrosion caused by chemical reactions. Therefore, chemical companies often choose copper pipes when designing reaction equipment to ensure the long-term stability and safety of the equipment. Particularly in acidic and alkaline environments, large copper tubes with an outer diameter of 28-54mm provide excellent protection, reducing equipment damage and production accidents caused by corrosion.

Heavy Machinery and Automotive Manufacturing

In heavy machinery, automobiles, and engineering equipment, large copper tubes with an outer diameter of 28-54mm are often used in hydraulic systems and cooling systems. In these applications, copper pipes not only need to provide pressure resistance but also maintain their thermal conductivity in high-temperature environments. Large copper tubes with an outer diameter of 28-54mm are widely used in braking systems, hydraulic systems, engine cooling, and heat exchange. Due to copper's good thermal conductivity and corrosion resistance, it effectively prevents system overheating and corrosion, maintaining the stable operation of the equipment.

Power Industry

In the power industry, especially in the cooling systems of power plants, large copper tubes with an outer diameter of 28-54mm are often used in cooling water systems and heat exchange systems. Copper pipes can not only efficiently transfer heat but also withstand corrosive environments from long-term exposure to water or other cooling media. In addition, copper pipes are also commonly used in electrical wiring protection and other equipment requiring high temperature and high pressure resistance in power facilities.

What are the advantages of large copper tubes with an outer diameter of 28-54mm in terms of mechanical properties and corrosion resistance?

Large copper tubes with an outer diameter of 28-54mm have significant advantages over small-diameter copper tubes in terms of mechanical properties and corrosion resistance, which are particularly important in applications requiring high strength and corrosion resistance.

Advantages in Mechanical Properties

- High Strength and High Pressure Resistance: Large copper tubes with an outer diameter of 28-54mm typically have thicker walls, allowing them to withstand higher pressures and external forces. Their pressure-bearing capacity makes them particularly suitable for systems requiring the transport of high-pressure gases or liquids, such as oil and natural gas transmission systems and high-pressure condensers. In high-pressure environments, large copper tubes can maintain their shape and strength, preventing pipe bursts or deformation.

- Bending and Impact Resistance: Due to their larger diameter and thicker walls, large copper tubes with an outer diameter of 28-54mm have stronger resistance to bending and impact. This provides greater stability in complex environments, such as high-temperature, high-pressure, or transportation pipeline installations. Bending resistance is especially important in applications such as hydraulic systems and oil and gas transmission systems, where pipes are susceptible to external impacts or bending forces.

- Good Ductility and Toughness: Copper material itself possesses excellent ductility and toughness, maintaining good shape and performance even under high temperatures or pressures. When subjected to pressure overload or temperature changes, large copper tubes with an outer diameter of 28-54mm can adapt to deformation without cracking or fracturing. This characteristic makes copper tubes particularly outstanding in extreme environments, such as equipment requiring high temperature and high pressure resistance in the petrochemical and metallurgical industries.

Advantages of Corrosion Resistance

- Chemical Corrosion Resistance: Copper is a highly corrosion-resistant metal, especially in acidic or alkaline environments. Large copper tubes with an outer diameter of 28-54mm can effectively resist chemical corrosion from substances such as chlorides and sulfides, and are therefore widely used in chemical, pharmaceutical, and other transportation systems involving corrosive media. Particularly in the petrochemical industry, large copper tubes with an outer diameter of 28-54mm can operate stably for extended periods in highly corrosive environments, preventing equipment failure due to corrosion.

- Oxidation Resistance: A protective oxide film (such as patina) naturally forms on the surface of copper, effectively preventing further oxidation or rusting of the copper pipe. In humid or rainy environments, copper pipes are not easily affected by oxidation, thus extending their service life. For pipelines exposed to the atmosphere for extended periods, large copper tubes with an outer diameter of 28-54mm have a significant advantage over other metal materials (such as iron or steel pipes).

- Seawater Corrosion Resistance: Large copper tubes with an outer diameter of 28-54mm are particularly suitable for seawater or other saline environments. Copper has extremely high corrosion resistance to chloride ions in seawater, making large copper tubes with an outer diameter of 28-54mm an ideal choice for marine engineering and shipbuilding. For example, copper pipes in offshore oil platforms and seawater cooling systems are often exposed to harsh marine environments, and large copper tubes with an outer diameter of 28-54mm can effectively prevent corrosion caused by salt, extending the service life of the equipment.

Precautions During Transportation and Installation of Large Copper Tubes with an Outer Diameter of 28-54mm

During the transportation and installation of large copper tubes with an outer diameter of 28-54mm, especially those manufactured by Zhejiang Jingliang Copper-Tube Products Co., Ltd., a series of details need to be considered to ensure that the tubes are not damaged during transportation and maintain their excellent performance during installation. As a reliable partner in the copper tube industry, Zhejiang Jingliang Copper-Tube Products Co., Ltd., with its thirty years of experience and strong production capacity, has rigorous quality control standards for transportation and installation.

Precautions During Transportation

Due to the large outer diameter and heavy weight of large copper tubes with an outer diameter of 28-54mm, meticulous measures must be taken during transportation to avoid damage. The following are some key transportation precautions:

- Proper Packaging and Protection: For large copper tubes with an outer diameter of 28-54mm, Zhejiang Jingliang Copper-Tube Products Co., Ltd. uses professional packaging materials for protection during transportation. Since the surface of copper tubes is susceptible to scratches and impact damage, various protective measures such as foam, plastic film, or wooden crates are used to ensure that every copper tube arrives safely at its destination. At the same time, the company focuses on environmental protection in its packaging, using recyclable materials and complying with industry sustainability standards.

- Moisture and Corrosion Prevention: Although large copper tubes with an outer diameter of 28-54mm have strong corrosion resistance, special attention is still needed to prevent moisture in humid or rainy environments. The copper tube products provided by Zhejiang Jingliang Copper-Tube Products Co., Ltd. will use moisture-proof bags or desiccants during transportation, especially when transported to areas with a maritime climate or humid environments. In addition, while a natural oxide film forms on the surface of the copper tubes, extra measures, such as sealed packaging, will still be taken during transportation to prevent damage to the copper tube surface.

- Transportation and Loading:

Large copper tubes with an outer diameter of 28-54mm are heavy, requiring transportation vehicles with sufficient load-bearing capacity. Zhejiang Jingliang Copper-Tube Products Co., Ltd. utilizes an advanced fleet of transportation vehicles and lifting equipment to ensure that no unnecessary stress or damage is caused to the pipes during transportation. The copper tubes need to be evenly distributed on the transport vehicle to prevent deformation or bending. The company's convenient location in eastern China, near major cities like Shanghai and Ningbo, also ensures smooth transportation routes and shorter delivery times.

Precautions During Installation

Precautions during installation, especially for large copper tubes with an outer diameter of 28-54mm, involve precise dimensional control and correct process procedures.

- Pipe Support and Fixing:

Large copper tubes with an outer diameter of 28-54mm require an appropriate support system during installation, especially in long-distance installations or in situations requiring the pipes to withstand significant weight and pressure. Due to the high-quality standards and precise dimensions of Zhejiang Jingliang Copper-Tube Products Co., Ltd.'s copper tubes, large copper tubes with an outer diameter of 28-54mm offer higher stability during installation. During installation, it is recommended to use specialized brackets and fixing devices to prevent deformation or displacement of the copper tubes during system operation.

- Welding and Connection:

Since large copper tubes with an outer diameter of 28-54mm are widely used in high-pressure systems, the quality of welding and connections is particularly important. Zhejiang Jingliang Copper-Tube Products Co., Ltd.'s large copper tubes with an outer diameter of 28-54mm are manufactured using advanced extrusion and annealing processes, resulting in a smooth and flawless surface, facilitating subsequent welding and connections. When welding, appropriate welding materials should be selected, and the temperature and welding time should be carefully controlled to avoid pores, cracks, or other defects that could affect pipe performance. The welded copper tubes should undergo pressure testing to ensure that each pipe can withstand the system pressure.

- Preventing Pipe Deformation:

Large copper tubes with an outer diameter of 28-54mm may bend or deform due to improper handling during transportation and installation. To prevent this situation, Zhejiang Jingliang Copper-Tube Products Co., Ltd. has considered the strength and pressure resistance of copper tubes during product design and manufacturing. Therefore, special attention should be paid to avoiding any excessive external pressure during the installation of copper tubes. For long-distance laying, methods such as reinforced supports and flexible joints can be used to effectively prevent bending and deformation of the copper tubes, ensuring the stability of the pipeline system during long-term use.

- Dimensional Accuracy and Inspection:

Ensuring dimensional accuracy is crucial during the installation of large copper tubes with an outer diameter of 28-54mm. Zhejiang Jingliang Copper-Tube Products Co., Ltd. strictly controls the dimensional tolerances of the outer diameter, inner diameter, and wall thickness of the copper tubes, ensuring that the quality of each pipe meets the standards. Before installation, installers need to perform dimensional verification to ensure that the copper tubes match the installation location, avoiding installation problems caused by improper dimensions. Furthermore, after installation, the copper tube system should undergo a series of inspections, including pressure testing and airtightness testing, to ensure there are no leaks or damage, guaranteeing the long-term safe use of the pipeline system.

- Intelligent Construction and Efficient Management:

Zhejiang Jingliang Copper-Tube Products Co., Ltd. not only focuses on the production quality of copper tubes but also improves production and management efficiency through intelligent manufacturing technology. The company uses advanced information management systems and production monitoring methods to ensure that every aspect of the production process, transportation, and installation of large copper tubes with an outer diameter of 28-54mm meets the highest standards. At the same time, the company provides technical support to customers during the installation process to ensure the perfect installation of copper tube products.

Advantages and Support of Zhejiang Jingliang Copper-Tube Products Co., Ltd.

Zhejiang Jingliang Copper-Tube Products Co., Ltd., with its strong production capacity and comprehensive service system, provides customers with high-quality large copper tubes with an outer diameter of 28-54mm and professional technical support. Since its establishment in 1994, the company has accumulated rich production experience and, through a strict quality control system, ensures the superior performance of large copper tubes with an outer diameter of 28-54mm in any application. The company boasts a 20,000-square-meter production base and advanced processing technology, with an annual production capacity exceeding 7,500 tons, enabling it to meet the high demand for large copper tubes with an outer diameter of 28-54mm from domestic and international customers.

Located in Zhejiang Province, a region with convenient transportation access and proximity to several important ports and logistics centers, Zhejiang Jingliang Copper-Tube Products Co., Ltd. ensures that its products can reach domestic and international markets quickly. The company consistently follows meticulous management practices in product transportation and installation, ensuring that every step protects the integrity of the copper tube products to the greatest extent possible.

English

English Español

Español 中文

中文