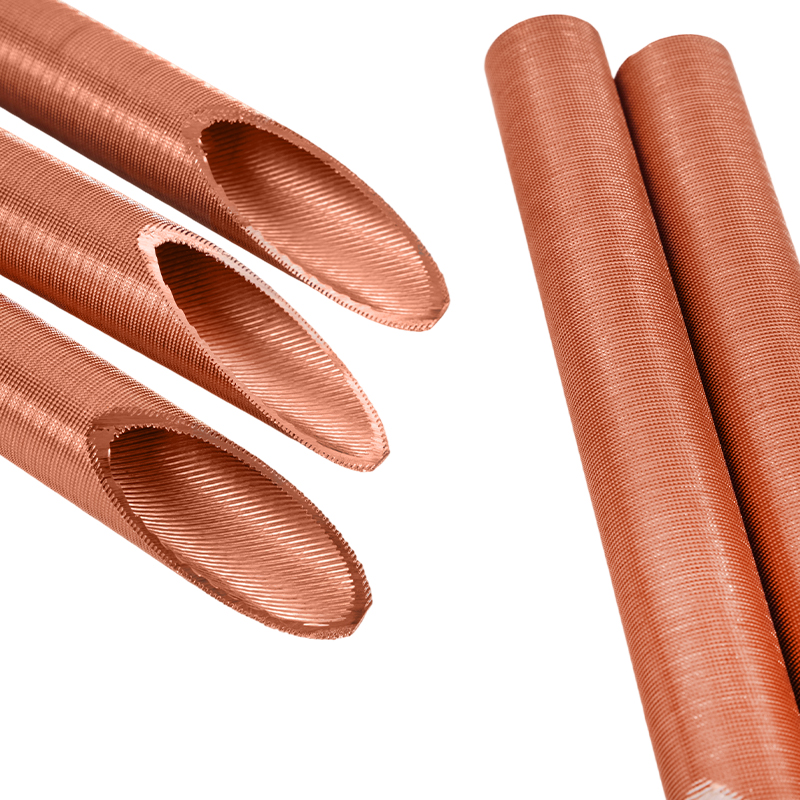

The condenser copper tube adopts a proprietary design independently developed by the company, and the ends of the fins are provided with radial and axial sharp protrusions. This structure significantly increases the heat exchange area in the tube, effectively breaks the refrigerant liquid film, destroys the surface tension of the liquid, enhances the flushing effect of the condensate, promotes the rapid removal of the condensate, and greatly improves the heat exchange efficiency. This product uses high-purity copper materials, has thermal conductivity and corrosion resistance, can adapt to a variety of refrigerants and complex working conditions, and can operate stably for a long time. This product is widely used in central air-conditioning centrifugal units, screw machines and other large refrigeration equipment, especially suitable for shell and tube heat exchangers with small temperature differences and various heat exchange systems involving phase change heat exchange.

ABOUT US

30+YEARS OF

EXPERIENCE

About Us

A Reliable Partner of the Copper Tube Industry

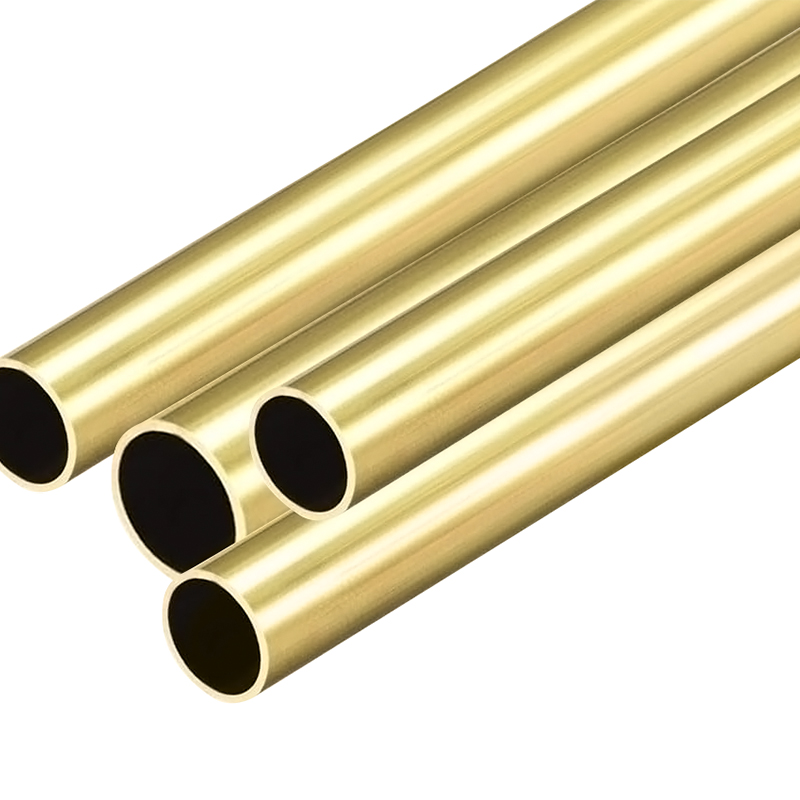

Zhejiang Jingliang Copper-Tube Products Co., Ltd established in 1994, is China Condenser Copper Tube Manufacturers and Custom Copper Tube Condenser Suppliers, has been deeply involved in the copper tube industry for over three decades. The company primarily produce various specifications of products such as copper tubes, brass tubes, copper square tubes, fin copper tubes, copper capillary tubes, condenser copper tubes, copper evaporator tubes, and conductive rods, which are of quality and have earned the trust and acclaim of customers both domestically and internationally.

Wide Applications:

These products are widely used in various fields including air conditioning, refrigeration, heat exchange, sanitary ware, automotive, machinery, electric furnaces, and chemical industries.

Convenient Transportation:

Strategically located in Tangpu Town, renowned as the “home of copper tubes” in East China. Our company enjoys a prime location, adjacent to the Shangsan Expressway and National Highway 104, and is conveniently situated just over 70 kilometers from Hangzhou and Ningbo, ensuring easy accessibility and a business position.

Strong Financial Resources:

With its strong financial resources and advanced copper tube processing technology, our company holds an advantageous position in market share, brand value, technological content, and product quality, becoming a preferred supplier for many listed groups.

Large Scale Production:

The company occupies an area of over 20,000 square meters, with a construction area of 12,800 square meters. In 2022, our annual production exceeded 7,500 tons, with a value output of up to 450 million yuan, demonstrating our strong production capacity and market competitiveness.

Comprehensive Industry Chain:

Jingliang has now developed into a complete industrial chain integrating smelting, extrusion, drawing, precision rolling, and annealing. It has been awarded multiple honors, including "Top Ten Copper Tube Enterprises" and "Leading Taxpayer in the Copper Tube Industry".

Smart Manufacturing:

Jingliang Copper-Tube Products will better integrate the concept of factory construction into its corporate development strategy, insist on refining technology and polishing products more finely, and the future of "intelligent manufacturing".

Genuine Cooperation:

Zhejiang Jingliang Copper-Tube Products Co.,Ltd warmly welcomes friends from all walks of life to visit and offer guidance. We look forward to joining hands with you to create a brilliant future together.

Technical skills

Production Process

- 1、Electrolytic Copper

- 2、Copper Ingots

- 3、Press

- 4、Drawing

- 5、Rolling

- 6、Packaging

Electrolytic copper, produced through electrolytic processes, is a high-purity copper with good electrical conductivity and thermal conductivity, making it an ideal material for manufacturing copper pipes.

This marks the beginning of our production process, which involves the fabrication of electrolytic copper into pure copper or brass ingots according to specific requirements, followed by cutting to facilitate subsequent processing and handling.

In the pressing stage, the cut copper ingots are pressed into thin sheets or tubular shapes, forming the initial tube shape, and the copper ingots are prepared for drawing and rolling.

Drawing is the process of further processing the copper sheets or tubular objects that have been pressed into the required dimensions and shapes. Through drawing, our copper tubes can achieve precise outer diameters and wall thicknesses.

Rolling is the step of further processing the copper tubes after drawing. Through rolling, the copper tubes are rolled into more precise dimensions and shapes to meet the requirements of different applications.

Finally, the copper tubes that have undergone rolling will be packaged and prepared for shipping. We ensure that the packaging is safe and protective to prevent damage during transportation.

News

-

Introduction: The Heart of Modern Thermal Management In an era where energy efficiency is no longer a luxury but a global mandate, the demand for high-performance thermal components has reached an all-time high. Under the mounting pressure ...

READ MORE -

Despite a challenging global market environment, Zhejiang Jingliang Copper-Tube Products Co., Ltd. recently held its Annual Summary Conference to review the past year’s achievements and outline strategies for the year ahead. The meeting bro...

READ MORE -

Navigating the World of Brass Tube Manufacturing In the modern industrial landscape, the brass tube remains an unsung hero. Renowned for its exceptional corrosion resistance, superior thermal conductivity, and ease of machining, brass is th...

READ MORE

Industry knowledge

What are the main applications of copper condenser tubes?

Copper condenser tubes are widely used in various applications requiring heat exchange, cooling, and condensation. Copper, due to its excellent thermal conductivity, corrosion resistance, and mechanical properties, is used as the core material for condensers in many industries.

Air Conditioning and Refrigeration Industry: Copper condenser tubes play a vital role in air conditioning and refrigeration equipment. The condenser converts high-temperature, high-pressure refrigerant gas into liquid, releasing heat. Copper tubes have excellent thermal conductivity, helping to quickly transfer heat and ensure efficient operation of the equipment. Copper condenser tubes are essential components in home air conditioners, commercial freezers, and large cold storage systems. Copper tubes' high pressure resistance and corrosion resistance make them particularly suitable for these applications.

Automotive Air Conditioning Systems: Copper tubes are also used in the condensers of automotive air conditioning systems. These tubes are often bent and assembled to form complex condenser structures. When the automotive air conditioning system is operating, the copper condenser tubes are responsible for dissipating heat from the refrigerant into the air, maintaining a comfortable temperature inside the vehicle. In this application, copper tubing's high thermal conductivity and durability ensure long-term, stable operation of vehicle air conditioning systems under high temperatures and loads.

Refrigerant Recovery and Cooling Systems: In industrial cooling systems, condenser copper tubing is used in heat dissipation and heat exchangers, such as in large refrigeration systems, air conditioning equipment, and industrial cooling towers. Condenser copper tubing effectively transfers heat to the air or cooling water, ensuring proper system operation and energy savings. In many chemical plants and pharmaceutical industries, these equipment have stringent temperature control requirements, making copper tubing a key choice.

Water Heaters and Solar Water Heating Systems: Copper tubing is used as a heat exchanger in some water heaters and solar water heating systems. In solar water heating systems, copper tubing effectively carries solar-heated hot water while ensuring efficient heat transfer. Copper's high thermal conductivity allows it to quickly absorb solar energy, significantly improving the efficiency of the water heating system.

Steam Boilers and Heat Exchangers: Copper tubing is also widely used in steam boilers and heat exchangers, particularly where efficient heat exchange is required. Copper tubing can withstand high temperatures and high pressures, maintaining stability and corrosion resistance even in high-temperature steam and other media. Heat exchanger designs often require efficient heat transfer, making copper tubing one of the most suitable materials.

What are the technical requirements for condenser copper tubes?

As an essential component in refrigeration, air conditioning, and other heat exchange equipment, condenser copper tubes must meet a series of stringent technical requirements to ensure long-term stable and efficient operation. To meet these requirements, Zhejiang Jingliang Copper-Tube Products Co., Ltd., with over three decades of industry experience, is committed to providing high-quality copper tubing products and offering customers solutions that meet various operating conditions.

Thermal Conductivity and Heat Transfer Performance Requirements

One of the core technical requirements of condenser copper tubes is their excellent thermal conductivity. Copper, as one of the metals with the highest thermal conductivity, effectively conducts heat during the condensation process, making condenser copper tubes widely used in air conditioning, refrigeration, chemical, and other heat exchange systems. Zhejiang Jingliang Copper-Tube Products Co., Ltd.'s production process strictly controls the purity of its copper tubes to ensure their thermal conductivity meets or exceeds industry standards. Through precise manufacturing processes, Zhejiang Jingliang Copper-Tube Products Co., Ltd.'s products provide excellent heat exchange efficiency, meeting customers' demand for high-performance condensers.

Corrosion Resistance Requirements

Copper tubes are subject to long-term operation in corrosive environments, particularly those exposed to moisture, chlorides, and acids found in refrigeration and air-conditioning equipment. Therefore, copper tubes must possess high corrosion resistance. Zhejiang Jingliang Copper-Tube Products Co., Ltd. uses high-quality copper alloys, such as nickel-copper alloy or phosphor copper, to enhance the corrosion resistance of its copper tubes. Advanced surface treatments, such as nickel plating or protective coatings, ensure the copper tubes' resistance to corrosion and oxidation over long-term use. The company's products are frequently used in the marine and chemical industries, where corrosion resistance is paramount. These technologies ensure that the copper tubes can operate stably in these harsh environments, extending the life of the equipment.

Mechanical Performance Requirements

Condenser copper tubes are required to withstand varying degrees of pressure, especially when operating in high-temperature and high-pressure environments. The copper tubes must possess sufficient mechanical strength to prevent deformation or leakage. Therefore, the wall thickness, tensile strength, and compressive strength of the copper tubes must be strictly controlled. Zhejiang Jingliang Copper-Tube Products Co., Ltd., with its extensive production capacity and advanced copper tube processing technology, is able to produce copper tubes that meet these high mechanical performance requirements, ensuring stable operation in high-pressure condensing systems. The company utilizes precision drawing, annealing, and rolling processes to ensure that each copper tube has precisely consistent dimensions and shape, avoiding performance issues caused by uneven wall thickness.

Dimensional Accuracy and Consistency

The dimensional accuracy of condenser copper tubes is critical to the performance of the entire system. Excessive tolerances can prevent the copper tubes from being precisely connected to other components, affecting the system's sealing and heat exchange efficiency. Zhejiang Jingliang Copper-Tube Products Co., Ltd. utilizes modern production equipment and a rigorous quality control system to ensure that each copper tube meets stringent dimensional standards. Through high-precision extrusion, drawing, and measurement technologies, Zhejiang Jingliang Copper-Tube Products Co., Ltd. is able to produce copper tubes that meet international standards for diameter, wall thickness, and tolerances, ensuring high consistency during assembly and operation.

High-Temperature and High-Pressure Resistance

Condenser copper tubes are subject to high temperatures and high pressures during operation, particularly in large cooling systems and refrigeration units. Zhejiang Jingliang Copper-Tube Products Co., Ltd. focuses on copper material quality control during production and utilizes advanced annealing processes to ensure the tubes maintain excellent performance at elevated temperatures, preventing thermal expansion and cracking. The high-temperature and high-pressure resistance of condenser copper tubes effectively ensures the long-term stability of condensing systems under extreme operating conditions.

Compliance with International Standards and Certifications

As a company with over 30 years of experience in the copper tube industry, Zhejiang Jingliang Copper-Tube Products Co., Ltd. strictly adheres to international standards in its production. Its products meet multiple certifications, including ASTM and ISO, ensuring that its technical specifications and quality remain industry-leading. The company has long been committed to improving innovative technologies and exquisite craftsmanship, enabling its products to meet the high standards of domestic and international markets for condenser copper tubes.

How is the corrosion resistance of condenser copper tubes guaranteed?

As a crucial component of the condenser, the corrosion resistance of copper tubes is a key factor affecting the long-term reliability and efficiency of the condenser.

Optimizing Alloy Composition: Copper itself has a certain degree of corrosion resistance, but to enhance its corrosion resistance in complex environments, many condenser copper tubes use copper alloys. The addition of alloying elements such as nickel, tin, and phosphorus can significantly improve the corrosion resistance of copper tubes, especially in humid, chlorine-containing, or acidic environments. For example, nickel-plated copper tubes effectively resist salt spray corrosion, while phosphorus copper tubes offer strong corrosion resistance in high-temperature environments. Depending on the operating environment, the alloy ratio and material composition of the copper tubes can be adjusted to suit specific corrosive environments.

Surface Treatment Technology: Surface treatment of condenser copper tubes is a crucial step in ensuring their corrosion resistance. Common surface treatment methods include nickel plating, coating, and passivation. Nickel plating not only effectively prevents oxidation but also improves the hardness and wear resistance of copper tubes. Surface passivation forms a dense oxide film on the copper tube surface, effectively reducing the corrosion induced by chemicals in the environment. Coating technologies (such as polyurethane coating and epoxy coating) provide an additional layer of protection, preventing direct contact between chemicals and moisture.

Design Optimization: The design of condenser copper tubes is also a key factor in corrosion resistance. A rational piping layout and good drainage design can reduce the accumulation of moisture and impurities inside the copper tubes, preventing them from becoming corrosion sources. Some advanced condenser designs use internally threaded copper tubes, which increase the fluid contact area on the copper tube surface, enhancing heat exchange efficiency while reducing the risk of water droplet stagnation and corrosion.

Environmental Adaptability: The corrosion resistance of condenser copper tubes is closely related to their application environment. Especially in environments with seawater or strong chemical corrosion, copper tubes often require additional protective measures, such as copper tube coatings or the use of corrosion-resistant copper alloys. For marine environments, copper-tin alloy copper tubes (such as aluminum bronze) offer enhanced resistance to seawater corrosion, significantly extending the lifespan of the condenser copper tube in these extreme environments.

Through these multi-faceted measures, the corrosion resistance of the condenser copper tube is effectively guaranteed, thereby extending the equipment's service life and improving the operational stability and efficiency of the condenser system.

English

English Español

Español 中文

中文