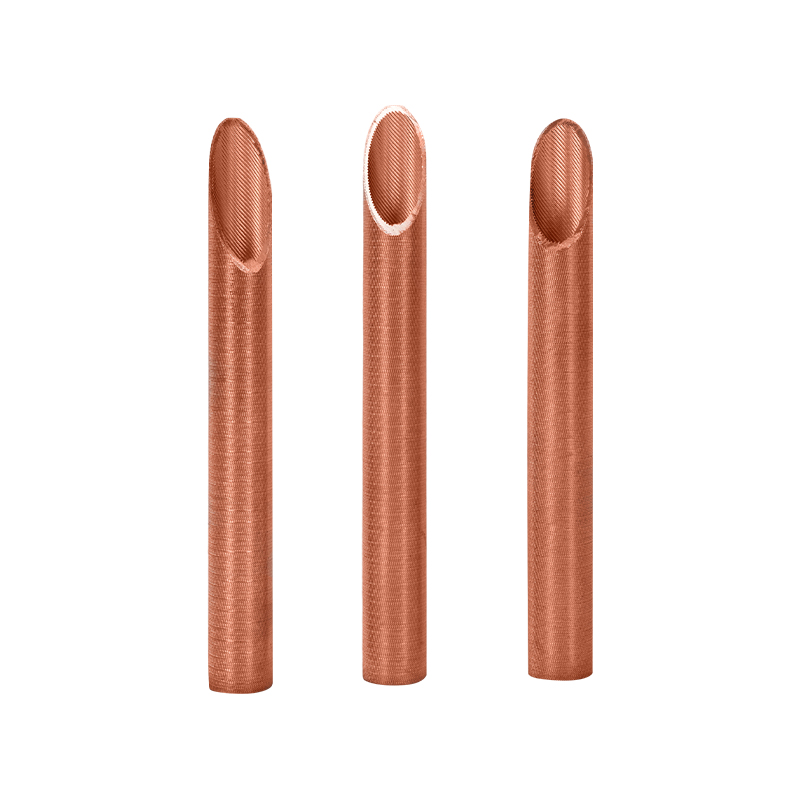

The copper evaporator tube adopts a unique fin design, and the external fins are equipped with specially designed interconnected channels, so that each fin is connected to each other to form a complete liquid evaporation surface. This special structure can produce a large number of stable vaporization nuclei in the full liquid evaporator, promote the frequent flow and evaporation of the refrigerant liquid in the channel, promote the continuous release of refrigerant bubbles, and significantly enhance the boiling heat exchange effect. The heat transfer performance of the copper evaporator tube is extremely, and its heat transfer coefficient can reach more than 7 times that of ordinary light tubes, greatly improving the thermal efficiency of the system. The inner wall of the tube has been strengthened to minimize the thermal resistance of the inner wall and ensure efficient heat transfer. The maximization of the dual heat exchange capacity inside and outside makes the copper evaporator tube excel in the field of efficient evaporation heat exchange. This product is suitable for full liquid evaporators of large chillers such as central air-conditioning centrifugal units and screw machines, and is also widely used in shell and tube heat exchangers under small temperature difference conditions.

ABOUT US

30+YEARS OF

EXPERIENCE

About Us

A Reliable Partner of the Copper Tube Industry

Zhejiang Jingliang Copper-Tube Products Co., Ltd established in 1994, is China Copper Evaporator Tube Manufacturers and Custom Copper Evaporator Tube Suppliers, has been deeply involved in the copper tube industry for over three decades. The company primarily produce various specifications of products such as copper tubes, brass tubes, copper square tubes, fin copper tubes, copper capillary tubes, condenser copper tubes, copper evaporator tubes, and conductive rods, which are of quality and have earned the trust and acclaim of customers both domestically and internationally.

Wide Applications:

These products are widely used in various fields including air conditioning, refrigeration, heat exchange, sanitary ware, automotive, machinery, electric furnaces, and chemical industries.

Convenient Transportation:

Strategically located in Tangpu Town, renowned as the “home of copper tubes” in East China. Our company enjoys a prime location, adjacent to the Shangsan Expressway and National Highway 104, and is conveniently situated just over 70 kilometers from Hangzhou and Ningbo, ensuring easy accessibility and a business position.

Strong Financial Resources:

With its strong financial resources and advanced copper tube processing technology, our company holds an advantageous position in market share, brand value, technological content, and product quality, becoming a preferred supplier for many listed groups.

Large Scale Production:

The company occupies an area of over 20,000 square meters, with a construction area of 12,800 square meters. In 2022, our annual production exceeded 7,500 tons, with a value output of up to 450 million yuan, demonstrating our strong production capacity and market competitiveness.

Comprehensive Industry Chain:

Jingliang has now developed into a complete industrial chain integrating smelting, extrusion, drawing, precision rolling, and annealing. It has been awarded multiple honors, including "Top Ten Copper Tube Enterprises" and "Leading Taxpayer in the Copper Tube Industry".

Smart Manufacturing:

Jingliang Copper-Tube Products will better integrate the concept of factory construction into its corporate development strategy, insist on refining technology and polishing products more finely, and the future of "intelligent manufacturing".

Genuine Cooperation:

Zhejiang Jingliang Copper-Tube Products Co.,Ltd warmly welcomes friends from all walks of life to visit and offer guidance. We look forward to joining hands with you to create a brilliant future together.

Technical skills

Production Process

- 1、Electrolytic Copper

- 2、Copper Ingots

- 3、Press

- 4、Drawing

- 5、Rolling

- 6、Packaging

Electrolytic copper, produced through electrolytic processes, is a high-purity copper with good electrical conductivity and thermal conductivity, making it an ideal material for manufacturing copper pipes.

This marks the beginning of our production process, which involves the fabrication of electrolytic copper into pure copper or brass ingots according to specific requirements, followed by cutting to facilitate subsequent processing and handling.

In the pressing stage, the cut copper ingots are pressed into thin sheets or tubular shapes, forming the initial tube shape, and the copper ingots are prepared for drawing and rolling.

Drawing is the process of further processing the copper sheets or tubular objects that have been pressed into the required dimensions and shapes. Through drawing, our copper tubes can achieve precise outer diameters and wall thicknesses.

Rolling is the step of further processing the copper tubes after drawing. Through rolling, the copper tubes are rolled into more precise dimensions and shapes to meet the requirements of different applications.

Finally, the copper tubes that have undergone rolling will be packaged and prepared for shipping. We ensure that the packaging is safe and protective to prevent damage during transportation.

News

-

Introduction: The Heart of Modern Thermal Management In an era where energy efficiency is no longer a luxury but a global mandate, the demand for high-performance thermal components has reached an all-time high. Under the mounting pressure ...

READ MORE -

Despite a challenging global market environment, Zhejiang Jingliang Copper-Tube Products Co., Ltd. recently held its Annual Summary Conference to review the past year’s achievements and outline strategies for the year ahead. The meeting bro...

READ MORE -

Navigating the World of Brass Tube Manufacturing In the modern industrial landscape, the brass tube remains an unsung hero. Renowned for its exceptional corrosion resistance, superior thermal conductivity, and ease of machining, brass is th...

READ MORE

Industry knowledge

What are the production processes for copper evaporator tubes?

The production process for copper evaporator tubes directly determines their performance and application effectiveness. Especially in the air conditioning, refrigeration, and heat exchange sectors, they require efficient heat exchange, corrosion resistance, and excellent mechanical properties. Zhejiang Jingliang Copper-Tube Products Co., Ltd., a leading company in the copper tube industry, has leveraged over 30 years of technological accumulation and innovation since its establishment in 1994 to continuously optimize its production process to meet the needs of a variety of complex and demanding applications.

Raw Material Selection and Alloy Design

The production of copper evaporator tubes begins with the selection of high-quality raw materials. Zhejiang Jingliang Copper-Tube Products Co., Ltd. uses high-purity copper and selects appropriate copper alloys based on specific applications. The company produces a variety of copper tubes, including pure copper and phosphor copper. Upon customer request, we can also provide copper tubes with special alloy compositions (such as copper-tin and copper-aluminum) to enhance corrosion and oxidation resistance in harsh environments. This customized raw material selection enables Copper Evaporator Tube to better meet the specialized needs of industries such as air conditioning, refrigeration, and chemicals.

Smelting and Casting

Copper smelting is a crucial step in Zhejiang Jingliang Copper-Tube Products Co., Ltd.'s production process. First, copper ore or copper scrap is converted into molten copper through high-temperature smelting, which is then cast. Controlling the copper's purity and composition is crucial during this process to ensure the copper tubes meet high standards for strength, thermal conductivity, and corrosion resistance. Zhejiang Jingliang Copper-Tube Products Co., Ltd. relies on advanced smelting equipment and strict quality control to ensure that each batch of copper ingots meets ideal quality standards, providing high-quality raw materials for subsequent tube production.

Extrusion and Drawing

Copper Evaporator Tubes are primarily formed through extrusion and drawing. Extrusion uses strong pressure to squeeze copper ingots into a tubular shape, while drawing involves stretching copper rods to form precise tubes. Through the drawing process, Zhejiang Jingliang Copper-Tube Products Co., Ltd. precisely controls the wall thickness and outer diameter of the copper tube, ensuring a high-precision, smooth surface. The size and shape of the copper tube are customized to meet the design requirements of different evaporator systems.

Annealing and Surface Treatment

Annealing is a key process to ensure that the copper tube has excellent ductility, toughness, and fatigue resistance. Zhejiang Jingliang Copper-Tube Products Co., Ltd. uses advanced annealing technology to enhance the copper tube's pressure resistance and high-temperature resistance during heat exchange. In addition, the copper tube undergoes surface treatments such as nickel plating and passivation to further enhance its corrosion resistance. For applications in marine or chemical environments, Zhejiang Jingliang Copper-Tube Products Co., Ltd. pays special attention to surface treatment to ensure that the copper evaporator tube can operate stably and for a long time in humid or corrosive environments.

Precision Rolling and Quality Inspection

During the production process, copper evaporator tubes undergo precision rolling to ensure dimensional accuracy, surface smoothness, and precise wall thickness. Zhejiang Jingliang Copper-Tube Products Co., Ltd. also strictly adheres to quality control standards at every stage of production, from raw materials entering the factory to finished products undergoing a series of inspections and tests. In particular, the copper tubes undergo comprehensive testing for air tightness, pressure resistance, and appearance, ensuring that each copper evaporator tube meets international quality standards.

What are the pressure resistance and high-temperature resistance of copper evaporator tubes?

Copper evaporator tubes play a key role in air conditioning and refrigeration systems. Their pressure resistance and high-temperature resistance are directly related to the stability and safety of the system. Zhejiang Jingliang Copper-Tube Products Co., Ltd.'s copper evaporator tubes, with their excellent pressure resistance and high-temperature tolerance, are widely used in various high-end heat exchange equipment.

Pressure Resistance

Copper evaporator tubes must withstand certain pressures in refrigeration systems, especially during compressor startup, when pressure inside the tubes fluctuates dramatically. Therefore, pressure resistance is particularly important. Copper's high strength and elasticity make copper evaporator tubes less susceptible to breakage or deformation when subjected to high pressures. Zhejiang Jingliang Copper-Tube Products Co., Ltd. manufactures copper evaporator tubes using various strengthening processes, such as annealing, cold working, and heat treatment, resulting in excellent pressure resistance. This ensures the copper tubes maintain their integrity, preventing leakage and damage, especially in operating environments subject to alternating high temperatures and high pressures.

In addition, the wall thickness and outer diameter of the copper tubes also significantly impact their pressure resistance. Zhejiang Jingliang Copper-Tube Products Co., Ltd. offers copper evaporator tubes in various wall thicknesses and specifications to meet customer needs, ensuring they can adapt to varying pressure environments and withstand the extreme pressures that may occur within the equipment.

High-Temperature Resistance

Copper, as a material with extremely high thermal conductivity, excels in high-temperature resistance in many industrial applications. In evaporator systems, copper evaporator tubes must not only withstand high pressures but also operate in high-temperature environments. Zhejiang Jingliang Copper-Tube Products Co., Ltd. further enhances the high-temperature resistance of copper tubes through alloy design and optimized production processes. For example, copper alloys containing elements such as aluminum and tin significantly improve the tube's stability at high temperatures, making it less susceptible to deformation or damage in environments with large temperature fluctuations.

Annealing also plays a key role in enhancing the high-temperature resistance of copper evaporator tubes. Through annealing, the copper tube's crystal structure is optimized, thereby enhancing its thermal stability in long-term high-temperature environments. Through this technical approach, Zhejiang Jingliang Copper-Tube Products Co., Ltd. ensures that copper evaporator tubes maintain excellent heat exchange performance and structural stability even during long-term use in high-temperature evaporator systems.

Copper Evaporator Tube Service Life and Maintenance Requirements

The service life and maintenance requirements of copper evaporator tubes are crucial to the long-term, stable operation of the entire refrigeration system. To ensure efficient heat exchange throughout the service life of the copper evaporator tubes, regular inspection and maintenance are essential. Zhejiang Jingliang Copper-Tube Products Co., Ltd., leveraging its years of production experience, is committed to providing high-quality copper tubes and offers relevant service life and maintenance recommendations.

Service Life

Copper evaporator tubes generally have a long service life. Especially under normal operating conditions, high-quality copper tubes can provide 15 to 30 years of stable service. However, the service life of copper tubes is affected by many factors, particularly the corrosive nature of the operating environment, temperature fluctuations, and pressure changes. Zhejiang Jingliang Copper-Tube Products Co., Ltd. utilizes highly corrosion-resistant copper alloys and advanced surface treatment technologies to significantly improve the corrosion resistance of copper evaporator tubes, extending their service life in humid, salt spray, and chemical environments.

The lifespan of the evaporator tubes is also affected by system design and maintenance. Proper tube design and installation can prevent damage caused by excessive bending or uneven pressure, thereby extending the lifespan of the copper evaporator tube.

Maintenance Requirements

To ensure long-term, stable operation of the copper evaporator tube, regular maintenance is required:

1. Cleaning and Anti-corrosion: Copper tubes should be cleaned regularly, especially during use, as they are prone to frost, dust, and other contaminants, which can reduce their heat exchange efficiency. For copper tubes used in marine or chemical environments, regularly inspect the surface for corrosion or oxidation, and implement anti-corrosion measures.

2. Inspect Connections: During copper evaporator tube installation, all connection points must be rigorously inspected to ensure proper sealing and prevent air or liquid leaks. Regularly inspect the pipe welds to prevent system failures caused by loose or corroded joints.

3. Temperature and Pressure Monitoring: Copper evaporator tubes must be protected from excessive temperature fluctuations or overload pressure during use. Therefore, temperature and pressure monitoring is crucial. This ensures the system operates within its normal operating range and prevents damage to the tubes from excessive thermal expansion or contraction.

4. Prompt Replacement of Damaged Parts: If cracks, corrosion, or other signs of damage are found on the copper evaporator tubes, they should be replaced promptly to avoid compromising the overall efficiency of the system.

Through regular inspection and maintenance, the copper evaporator tubes can maintain their efficient heat exchange performance over time, thereby improving the overall efficiency and lifespan of the refrigeration system. Zhejiang Jingliang Copper-Tube Products Co., Ltd. is committed to providing customers with high-quality, high-performance copper tube products. Through excellent after-sales service, we help customers extend the lifespan of their equipment and ensure long-term stable system operation.

English

English Español

Español 中文

中文