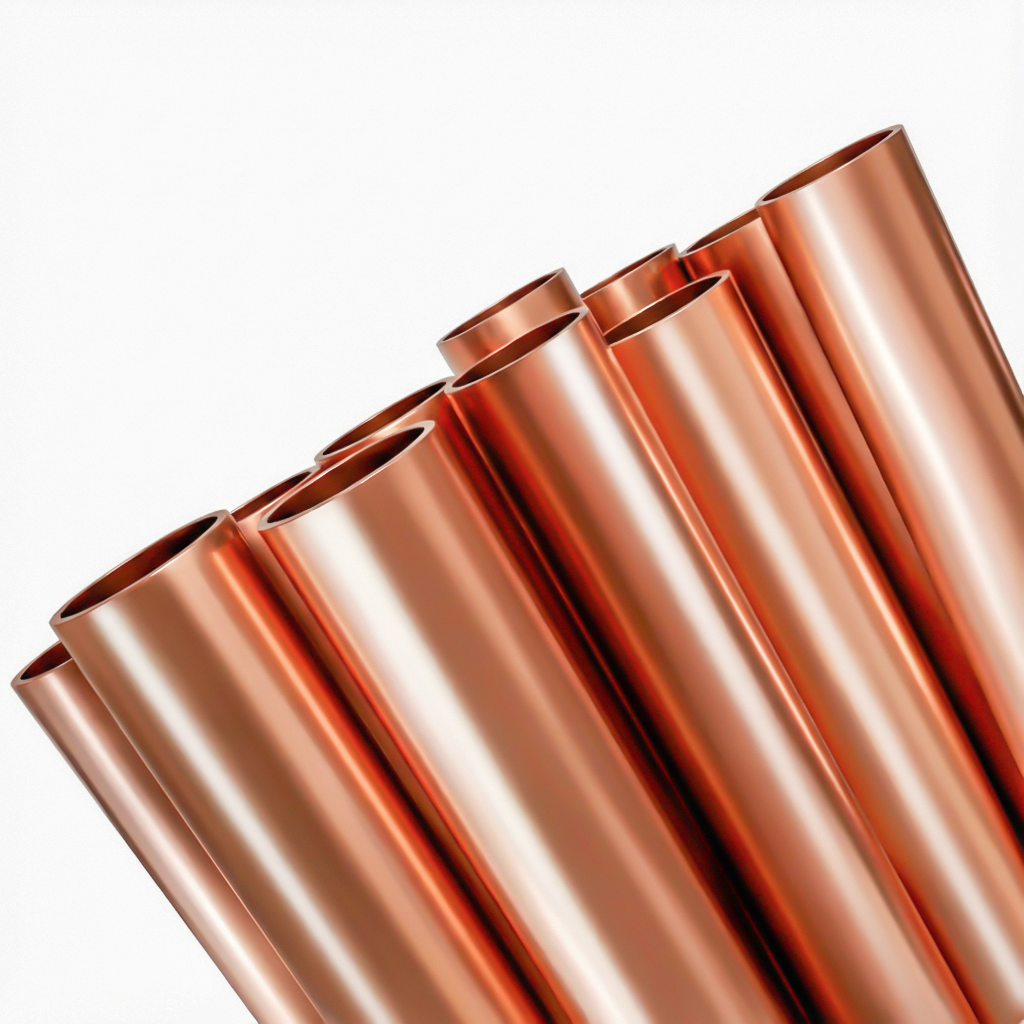

Copper tubes are the "blood vessels" of the refrigeration system, mainly used in condensers, evaporators and connecting pipelines. Its high thermal conductivity (with a thermal conductivity coefficient of approximately 400 W/m·K) enables rapid heat transfer, enhancing the energy efficiency ratio of air conditioners and refrigerators. The promotion of environmentally friendly refrigerants such as R410A has further driven the development of copper tubes towards high pressure resistance, thin-walled and lightweight. Industry standards such as ASTM B280 (Copper Tubes for Air Conditioning) have strict regulations on indicators such as cleanliness and tensile strength to avoid refrigerant leakage and system blockage.

What are the main application areas of conventional silver-copper alloy in industry?

Conventional silver-copper alloy is widely used in multiple industrial fields, and its unique properties give it an important position in high-end and specialized applications.

Electronics Industry: Conventional silver-copper alloy plays a significant role in the electronics industry. Its high electrical conductivity makes this alloy frequently used in the manufacture of electrical connectors, electrical contacts, sensors, and switches. The addition of silver significantly improves the alloy's conductivity, which is crucial for electronic components and high-frequency current conduction. Conventional silver-copper alloy is also used as solder in printed circuit boards (PCBs), effectively lowering the soldering temperature during the soldering process and maintaining good electrical performance over long periods of use.

Welding Industry: A significant advantage of conventional silver-copper alloy is its excellent weldability. This alloy can achieve high welding strength at lower temperatures and is commonly used in applications requiring high strength, high temperature resistance, and high conductivity. Silver-copper solder is widely used in welding electronic components, metal pipe connections, and precision welding. Due to its low melting point, conventional silver-copper alloy solder can complete the welding process with less heat damage while maintaining strong connection performance.

High-Temperature Environments: Conventional silver-copper alloy is widely used in components for high-temperature environments due to its excellent thermal conductivity. The combination of silver and copper allows the alloy to effectively conduct heat at high temperatures, preventing overheating and equipment failure. Therefore, these alloys are often used as materials for heat exchangers, engine components, and heating elements. Especially in some high-temperature furnaces and power generation equipment, conventional silver-copper alloy can operate continuously and stably under high thermal loads.

Automotive Industry: In the automotive industry, conventional silver-copper alloy is used in automotive electrical systems, such as sensors, battery connectors, and ignition systems. These alloys not only effectively conduct current but also withstand the high-temperature operating environment of car engines. Due to its corrosion resistance, conventional silver-copper alloy is also commonly used in automotive electrical interfaces and wiring, reducing damage to the electrical system from moisture, chemical corrosion, and other external factors.

Aerospace: The application of conventional silver-copper alloy in the aerospace field is mainly due to its excellent high-temperature stability and corrosion resistance. This alloy is used in aircraft engine components, aerospace electrical connectors, and communication equipment. Conventional silver-copper alloy maintains good mechanical strength in extreme environments, reducing equipment failures caused by temperature changes, vibrations, and other factors. Especially in satellites and spacecraft, conventional silver-copper alloy is often used in critical components requiring high stability and long lifespan.

Medical Equipment: In medical devices, conventional silver-copper alloy is often used to manufacture medical sensors, diagnostic equipment, and some special connectors due to its biocompatibility and corrosion resistance. These alloy materials ensure the long-term stable operation of the equipment and maintain high performance even after prolonged use.

Marine Industry: Due to the seawater corrosion resistance of conventional silver-copper alloy, its application in marine equipment is also very extensive. Key components of ship electrical systems, marine exploration equipment, and offshore oil and gas platforms may all use conventional silver-copper alloy to prevent corrosion and extend the service life of the equipment.

What are the unique advantages of conventional silver-copper alloy compared to other alloys?

Conventional silver-copper alloy possesses several unique advantages compared to other alloys, leading to its widespread application in various fields.

Excellent electrical and thermal conductivity: Silver has the best electrical conductivity of all metals, and copper is a close second. Conventional silver-copper alloy combines the advantages of these two metals, exhibiting extremely high electrical and thermal conductivity. This makes it particularly important in high-frequency electronic devices, power equipment, and heat exchange equipment. In contrast, other metals such as aluminum alloys have poorer conductivity, while conventional silver-copper alloy provides higher efficiency and stability in power transmission and high-temperature heat dissipation.

Good weldability: Due to the low melting point of silver, conventional silver-copper alloy performs exceptionally well during welding. Compared to other common alloys (such as copper-nickel alloys, aluminum alloys, etc.), conventional silver-copper alloy can be welded smoothly at lower temperatures, and the welded joints are stronger. This makes it particularly important in electronic products and precision instruments requiring fine welding.

Corrosion resistance: Conventional silver-copper alloy has stronger oxidation resistance than pure copper and many other copper alloys, especially in seawater or chemically corrosive environments. The addition of silver improves the alloy's resistance to chlorides, acids, and alkalis, making it widely used in marine equipment, chemical industry, and high-temperature environments, effectively preventing damage caused by corrosion.

High-temperature resistance: Conventional silver-copper alloy exhibits better stability in high-temperature environments than many other alloys, especially in applications requiring high-temperature operation (such as heat exchangers, engine components, etc.), maintaining good mechanical properties and chemical stability. In contrast, aluminum alloys and copper alloys may melt or experience performance degradation at high temperatures, while conventional silver-copper alloy can maintain stability for a longer period.

Mechanical properties and ductility: Conventional silver-copper alloy not only possesses high strength but also maintains good ductility. This means that they are less likely to break or deform when subjected to mechanical stress. Compared to other alloys such as copper-nickel alloys, conventional silver-copper alloys can better withstand loads in high-strength applications and exhibit better plasticity during processing.

Resistance to High-Frequency Electromagnetic Interference: Due to the excellent conductivity of conventional silver-copper alloys, they can effectively reduce electromagnetic interference (EMI), making them highly suitable for high-frequency communication equipment. Aluminum and copper alloys perform poorly in this regard and cannot provide the same shielding effect.

High Performance and Long Lifespan: The high conductivity and corrosion resistance of conventional silver-copper alloys result in lower maintenance costs during long-term use and improve the overall lifespan of equipment. Especially in high-precision equipment and long-running systems, conventional silver-copper alloys can reduce equipment failure rates, thereby improving equipment reliability and efficiency.

What are the oxidation resistance and corrosion resistance of conventional silver-copper alloy?

Conventional silver-copper alloy exhibits excellent oxidation resistance and corrosion resistance, especially in harsh environments such as high temperatures, high humidity, and exposure to corrosive chemicals. These properties make the alloy widely used in many industrial fields, particularly where high conductivity, thermal stability, and durability are required.

Oxidation Resistance: The oxidation resistance of conventional silver-copper alloy is primarily due to the addition of silver. Silver not only reduces the oxidation rate of copper at high temperatures but also prevents the formation of excessively thick oxide films, thus maintaining a smooth and even surface. For Zhejiang Jingliang Copper-Tube Products Co., Ltd., this characteristic of conventional silver-copper alloy is particularly suitable for applications requiring long-term efficient operation in air conditioners, refrigeration equipment, and heat exchangers. Since these devices typically operate in environments with high temperatures and significant humidity fluctuations, the oxidation resistance provided by conventional silver-copper alloy effectively extends the service life of the equipment and reduces maintenance costs.

Corrosion Resistance: Conventional silver-copper alloy demonstrates exceptional corrosion resistance, especially in harsh environments such as high humidity and salt spray. The addition of silver significantly enhances the corrosion resistance of copper, particularly in marine environments or chemical processes where prolonged exposure to corrosive gases or liquids is common. Zhejiang Jingliang Copper-Tube Products Co., Ltd.'s products, including copper tubes, copper capillary tubes, condenser copper tubes, and evaporator copper tubes, are widely used in the chemical industry, air conditioning, refrigeration, and automotive industries. Equipment in these fields is often exposed to corrosive gases or solutions. The corrosion resistance of conventional silver-copper alloy ensures that these copper tube products are not easily damaged during long-term use, thus ensuring the stability and reliability of the equipment.

High-Temperature Corrosion Resistance: For Zhejiang Jingliang Copper-Tube Products Co., Ltd., the stability of conventional silver-copper alloy at high temperatures is crucial. The company's copper tube products are widely used in heat exchangers, electric furnaces, and other high-temperature environments. Conventional silver-copper alloy effectively prevents high-temperature corrosion, ensuring stable operation even under high thermal loads. When conventional silver-copper alloys are used in heat exchange equipment, their excellent thermal conductivity and high-temperature corrosion resistance improve the heat exchange efficiency of the equipment and maintain low contact resistance under high-temperature conditions, which is crucial for improving the overall performance of the equipment.

Chemical Corrosion Resistance: Conventional silver-copper alloys perform excellently in many chemically corrosive environments, which has led to their widespread use in the chemical industry. Zhejiang Jingliang Copper-Tube Products Co., Ltd.'s copper tube products are often used in chemical reaction equipment, electrolytic cells, and heat treatment processes, where they are typically exposed to corrosive media such as strong acids, strong bases, or salt solutions. Conventional silver-copper alloys can resist corrosion from these media, extending the service life of the equipment and reducing downtime and maintenance caused by corrosion.

Chlorine Corrosion Resistance: Conventional silver-copper alloys also have strong resistance to chlorides, especially in marine environments. Conventional silver-copper alloys can effectively prevent corrosion caused by seawater or salt spray. For Zhejiang Jingliang Copper-Tube Products Co., Ltd., this characteristic is crucial in the application of its products in seawater cooling systems and offshore oil and gas platforms. In these extreme environments, the chlorine corrosion resistance of conventional silver-copper alloys ensures the long-term stable operation of the copper tubes, preventing equipment failure or damage due to chloride corrosion.

Comprehensive Application Scenarios: Various copper tube products manufactured by Zhejiang Jingliang Copper-Tube Products Co., Ltd., such as copper square tubes and copper finned tubes, have been widely used in air conditioning, automobiles, machinery, refrigeration, heat exchange, chemical processes, etc. The oxidation resistance and corrosion resistance of conventional silver-copper alloys enable these products to perform excellently in a variety of demanding application scenarios. In refrigeration and air conditioning equipment, copper tubes, as key conductive media, need to withstand frequent temperature fluctuations and environmental changes. The high corrosion resistance of conventional silver-copper alloys effectively resists the erosion of corrosive substances, ensuring the long-term stable operation of the equipment.

English

English Español

Español 中文

中文