Why Special Shaped Copper Tubes Are Becoming Essential in Automotive Design

In the rapidly evolving automotive industry, innovation and efficiency are more important than ever. As manufacturers look for ways to enhance vehicle performance, reduce weight, improve fuel efficiency, and comply with stringent environmental standards, they are increasingly turning to specialized materials. One such material that is gaining significant attention is special shaped copper tube. These copper tubes are revolutionizing automotive design by offering numerous advantages in terms of performance, durability, and sustainability.

The Growing Need for Special Shaped Copper Tubes in Automotive Design

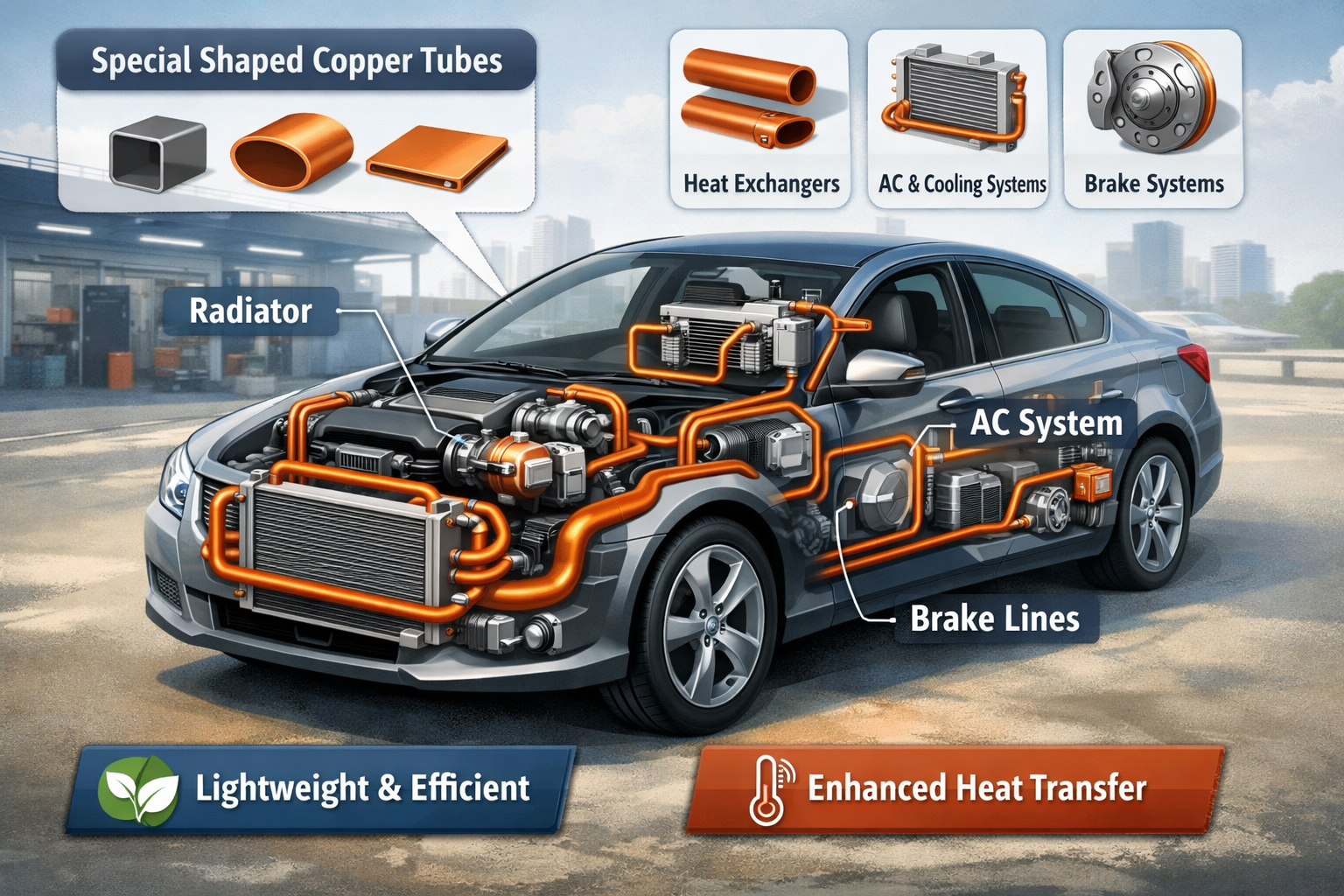

Automotive manufacturers are continuously under pressure to design vehicles that are lighter, more fuel-efficient, and more environmentally friendly. Special shaped copper tubes are emerging as a key solution in this pursuit. Unlike standard cylindrical copper tubes, special shaped copper tubes are available in a variety of configurations, including square, oval, and custom geometric shapes, allowing engineers to optimize the use of space in automotive systems. This ability to customize the shape and size of the tubes enables manufacturers to integrate them into compact and complex spaces, reducing the overall weight of the vehicle while maintaining optimal performance.

The versatility of these tubes is particularly beneficial in the context of modern vehicle systems, where compact designs and weight reduction are paramount. For example, special shaped copper tubes are increasingly being used in heat exchangers, radiators, air conditioning systems, and braking systems, where their ability to provide enhanced heat transfer and durability is a significant advantage.

(This image was generated by AI.)

Advantages of Special Shaped Copper Tubes

Enhanced Heat Transfer Efficiency

One of the most important applications of copper in automotive design is in heat exchangers and cooling systems. Copper is known for its excellent thermal conductivity, which makes it an ideal material for transferring heat. Special shaped copper tubes can further enhance heat transfer efficiency due to their unique shapes, which increase the surface area and allow for better heat dissipation.

In automotive systems such as air conditioning units, radiators, and intercoolers, the use of specially shaped copper tubes can significantly improve the overall cooling performance. For example, in radiators, these tubes can be designed in a way that maximizes airflow and heat dissipation, improving engine cooling and overall vehicle performance. This is particularly important for electric vehicles (EVs), where efficient thermal management is crucial for extending battery life and ensuring optimal operation.

| Application | Benefit | Example in Automotive Design |

| Heat Exchangers | Improved heat dissipation | Enhanced engine and battery cooling |

| Radiators | Better airflow and heat transfer | Optimized engine temperature control |

| Air Conditioning | Efficient thermal management | Increased cabin cooling in compact spaces |

Weight Reduction and Space Optimization

In the automotive industry, reducing weight is a primary objective. Lighter vehicles are more fuel-efficient, have lower emissions, and offer better handling and acceleration. Special shaped copper tubes contribute to weight reduction by allowing manufacturers to use less material without compromising strength or durability. The custom shapes can be designed to fit into tight spaces, thus optimizing the available space in the vehicle's structure and reducing the need for additional components.

For instance, special shaped copper tubes can be integrated into compact locations, such as air ducts or HVAC systems, without taking up excessive space. This makes it easier to design vehicles that are both lightweight and efficient, without sacrificing important features or performance.

| Key Benefit | Impact on Automotive Design |

| Weight Reduction | Improved fuel efficiency and reduced emissions |

| Space Optimization | More compact and efficient system designs |

Durability and Corrosion Resistance

Copper is well-known for its resistance to corrosion, which makes it a popular choice for automotive systems that are exposed to harsh environments, including high temperatures, moisture, and chemicals. Special shaped copper tubes offer the same benefits of corrosion resistance as traditional copper tubes, with the added advantage of being able to withstand high-pressure conditions. The custom shapes of the tubes can also contribute to greater mechanical strength and durability, making them ideal for critical automotive applications.

For example, in braking systems or hydraulic lines, where high pressure and stress are common, special shaped copper tubes are particularly useful due to their robust nature. The resistance to corrosion also helps extend the lifespan of these components, reducing the need for frequent maintenance and replacement.

| Application | Durability Feature | Example in Automotive Design |

| Braking Systems | High-pressure resistance | Longer lifespan, fewer replacements |

| Hydraulic Lines | Corrosion resistance | Reduced maintenance needs |

Improved Performance in Specific Automotive Systems

Special shaped copper tubes are increasingly being used in a variety of automotive subsystems, from cooling and heating systems to advanced braking mechanisms. Here are a few notable applications:

| System | Application of Special Shaped Copper Tubes | Benefit |

| Heat Exchangers and Radiators | Maximizing heat dissipation and airflow | Improved cooling for engine and battery |

| Brake Lines and Fuel Lines | Custom shapes to fit system needs | Enhanced durability and performance |

| Air Conditioning and HVAC | Compact tube designs for tight spaces | Efficient thermal management in confined areas |

| Electric Vehicles (EVs) | Thermal load management for batteries | Increased battery lifespan and safe operation |

The Environmental Benefits of Special Shaped Copper Tubes

With growing concerns over climate change and the increasing demand for environmentally friendly technologies, automotive manufacturers are focusing on sustainable solutions. Special shaped copper tubes contribute to these efforts in several ways:

1. Recyclability: Copper is a highly recyclable material, making it an eco-friendly choice for automotive design. Special shaped copper tubes can be recycled at the end of a vehicle’s life cycle, reducing waste and minimizing the environmental impact of production. This is particularly important as the automotive industry moves toward a circular economy model.

2. Energy Efficiency: As mentioned earlier, the superior thermal conductivity of copper allows for more efficient heat management in various automotive systems. This contributes to the overall energy efficiency of the vehicle, reducing energy consumption and lowering emissions. This is especially relevant as the industry moves towards electric and hybrid vehicles, where energy efficiency is a key factor in performance and sustainability.

| Environmental Benefit | Contribution to Automotive Design |

| Recyclability | Reduces waste and supports circular economy |

| Energy Efficiency | Lower energy consumption, reduced emissions |

The Role of Copper Tube Factories in Automotive Design

As the demand for special shaped copper tubes in automotive manufacturing grows, the role of copper tube factory becomes increasingly vital. These factories specialize in the production of custom copper tubes that meet the specific needs of automotive manufacturers. Copper tube factories employ advanced manufacturing techniques to produce a wide variety of tube shapes, sizes, and designs, ensuring that the final product is tailored to the unique requirements of the automotive industry.

These factories often use precision forming, bending, and welding techniques to create special shaped copper tubes that can withstand high pressures and temperatures while maintaining the highest standards of quality. By working closely with automotive manufacturers, copper tube factories can ensure that their products meet the stringent performance and safety standards required in the automotive sector.

Moreover, copper tube factories are constantly innovating, developing new ways to improve the production process, reduce waste, and lower costs. As technology continues to advance, these factories are becoming more efficient, making it easier for manufacturers to source high-quality, custom-shaped copper tubes for their automotive applications.

Challenges and Considerations

While special shaped copper tubes offer numerous benefits, there are some challenges and considerations that manufacturers need to take into account:

| Challenge | Consideration |

| Cost | Higher initial material cost but offset by long-term benefits |

| Manufacturing Complexity | Advanced techniques required for precision and custom shapes |

| Compatibility with Other Materials | Ensuring integration with other system components |

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文