How to Choose the Right Copper Tube Factory?

Global Demand for Copper Tubing Is Entering a New Growth Cycle

As global infrastructure undergoes large-scale upgrades—ranging from HVAC system replacements to energy-efficient building construction, heat-pump adoption, industrial cooling, and the accelerating electrification of transportation—the demand for high-quality copper tubing continues to rise. In HVAC, refrigeration, power engineering, heat exchangers, and sanitary systems, copper tubes remain one of the most trusted materials thanks to their excellent thermal conductivity, corrosion resistance, formability, and 100% recyclability.

From 2025 to 2030, the global copper tube market is expected to grow steadily due to the expansion of new energy vehicles, hydrogen energy, data-center liquid cooling, smart appliances, and large commercial HVAC systems. Manufacturers worldwide are investing heavily in modernization, intelligent manufacturing, and environmentally compliant production.

In this rapidly evolving market, choosing the right copper tube factory is becoming increasingly important. Below is an in-depth look at the world’s leading copper tube manufacturers in 2025 and how to evaluate and select the best supplier for HVAC copper pipe, refrigeration copper tubing, and industrial copper tube applications.

Top 5 Copper Tube Manufacturers in 2025

Mueller Industries, Inc. (USA)

Mueller remains the most influential copper tube factory in North America. Specializing in seamless copper tubing, HVAC copper pipe, refrigeration tubing, medical gas pipes, and plumbing-grade tubes, Mueller products comply with ASTM B280, B88, B306, and other US standards.

Competitive Strengths

- Strong US-based manufacturing footprint

- Reliable supply chain and stable delivery

- Advanced extrusion and draw-bench technology

- High-quality HVAC & refrigeration copper pipes with strict quality control

- Preferred supplier for major contractors, wholesalers, and OEMs

- Mueller’s consistent quality and dependable logistics make it the top copper tubing supplier for the US market.

Application scenarios

- Building HVAC

- Refrigeration systems

- Industrial fluid transfer

- Medical gas pipelines

Wieland Group (Germany / Global)

Wieland is one of the most technologically advanced manufacturers of copper and copper-alloy products. Its portfolio includes inner-grooved tubes, smooth tubes, heat-exchanger tubes, microfin tubes, and specialty alloys serving HVAC, power systems, construction, and industrial sectors.

Competitive Strengths

- 200+ years of manufacturing heritage

- Complete industrial chain: smelting → extrusion → drawing → finishing

- Strong R&D capability in high-precision copper tubing

- Leading “green copper” and recycled copper programs

- Plants in Europe, the US, and Asia ensure global availability

- Wieland is especially strong in precision heat exchanger copper tubing and sustainable manufacturing leadership.

KME Group (Italy / Europe / Global)

KME is a major global producer of copper and copper-alloy tubes. Its factories throughout Europe supply industrial copper tubing, automotive copper components, HVAC copper pipe, and specialty engineered products.

Competitive Strengths

- Large production scale and global market network

- Advanced multi-alloy processing capability

- Strong innovation in industrial and infrastructure copper tube solutions

- Active capital operations enabling capacity expansion and technology upgrades

- KME is widely recognized as a leading international copper tube manufacturer serving industrial and engineering projects.

Luvata (Finland / Global)

Luvata focuses on high-performance refrigeration copper tubing, heat-exchanger tubes, capillary tubes, and thin-wall copper tubes. Its products are widely used by HVAC and commercial refrigeration OEMs.

Competitive Strengths

- Excellent thermal conductivity performance

- Precision manufacturing with extremely low leakage rates

- Strong presence in global industrial cooling and heat-exchanger markets

- Stable international supply chain

- Luvata is a preferred copper tube supplier for customers requiring high reliability and tight tolerances.

Application scenarios

- Heat exchange

- Electronics manufacturing

- Medical equipment and high-power systems, etc.

Zhejiang Jingliang Copper-Tube Products Co., Ltd. (China)

Established in 1994, Jiangliang boasts over 30 years of experience in copper tube manufacturing and is one of the "Top 10 Copper Tube Enterprises" in China's industry.

Competitive Strengths

- Complete industrial chain from smelting → extrusion → drawing → annealing

- 7,500+ tons annual output

- Strong domestic and international market competitiveness

- Modernized manufacturing and digital quality control

- Cost-effective supplier for HVAC, refrigeration, and engineering copper tubes

- Jingliang is becoming one of the most globally competitive copper tube manufacturers from China.

Top 5 Copper Tube Factory in 2025

|

Ranking |

Company |

Region |

Strength Highlights |

|

1 |

Mueller Industries, Inc. |

USA |

Leading HVAC & plumbing grade copper tube producer with strong U.S. manufacturing footprint |

|

2 |

Wieland Group |

Germany & Global |

Full industrial chain, strong R&D and high-precision copper tubing solutions |

|

3 |

KME Group |

Europe |

A major international copper and copper alloy manufacturer powering industrial infrastructure |

|

4 |

Luvata Group |

Europe & Global |

Well-known copper tube supplier for refrigeration & heat-exchange applications with global production presence |

|

5 |

Zhejiang Jingliang Copper-Tube Products Co., Ltd |

China |

Smart manufacturing, strong financial capability, and recognized by Top Ten Copper Tube Enterprises |

Key Standards to Evaluate Copper Tube Manufacturers

A top copper tube supplier should meet:

American Standards

- ASTM B280 – Refrigeration copper tubing

- ASTM B88 – Plumbing copper tube

- ASTM B75 / B68 – Seamless copper tube

European Standards

- EN 12735-1 / EN 12735-2

- EN 1057 – Plumbing tubes

- EN 12449 – Copper alloy tubes

Environmental Standards

- ROHS / REACH

- Low carbon & recycled copper content

- Certification strength directly reflects the factory’s quality control system

- Factories with a full process chain can achieve better quality consistency, precise tolerances, and stronger cost control.

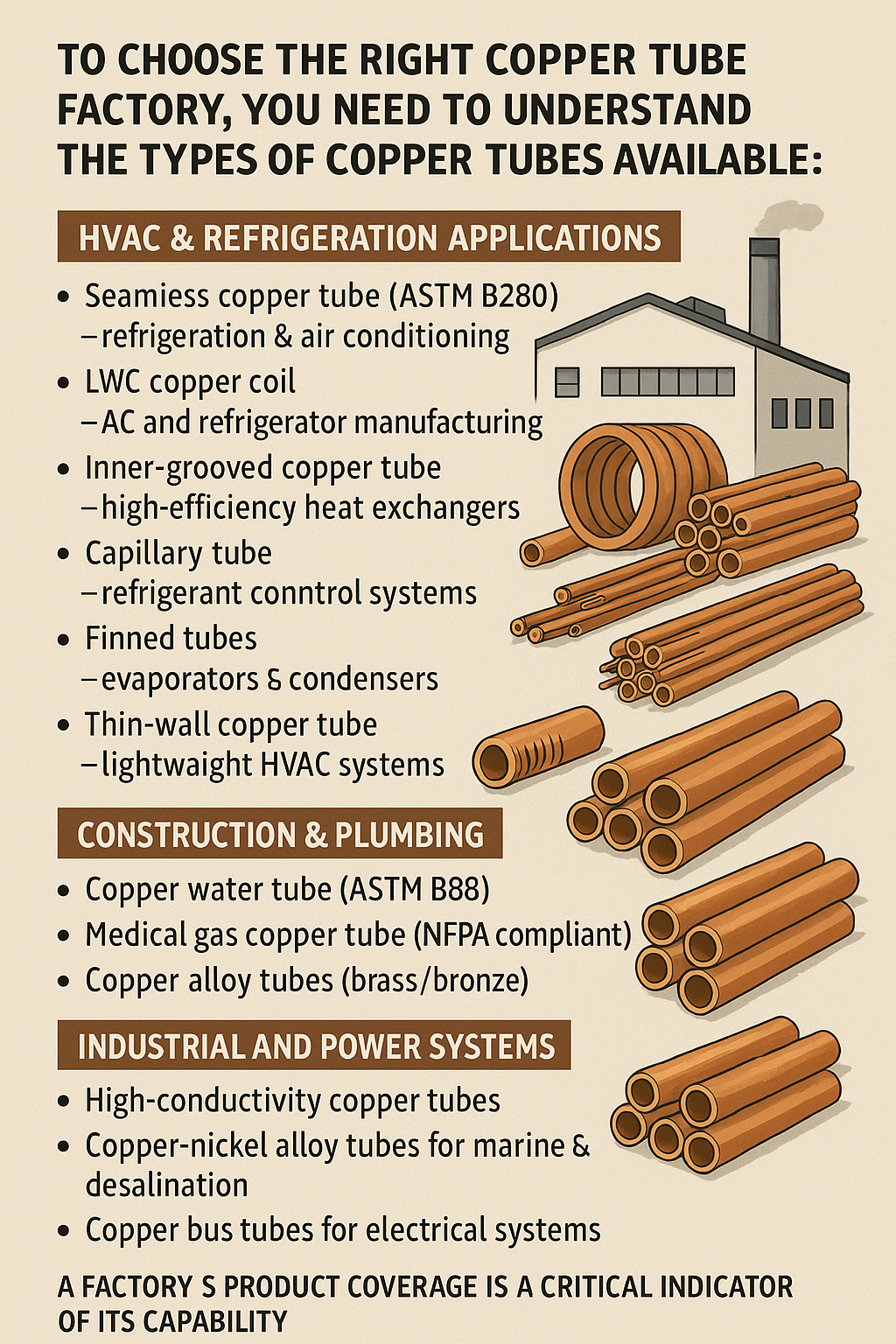

Types of Copper Tubes and Their Applications

Copper tubes, due to their excellent thermal conductivity, corrosion resistance, and ductility, are widely used in many industries, such as construction, refrigeration, HVAC (Heating, Ventilation, and Air Conditioning), automotive, and electronics. The following are common types of copper tubes and their applications:

Seamless Copper Tube

Standards: ASTM B280, ASTM B88, ASTM B75 / B68

Applications:

- Refrigeration and Air Conditioning Systems (HVAC): Seamless copper tubes are widely used in refrigeration and air conditioning systems, primarily for transporting refrigerants. Because they have no welded seams, seamless copper tubes offer higher strength and pressure resistance, making them suitable for withstanding higher operating pressures.

- Medical Gas Piping: In hospitals and medical facilities, seamless copper tubes are often used to transport pure oxygen and other medical gases because copper has natural antibacterial properties, effectively reducing the risk of bacterial transmission.

- Building and Plumbing Systems: Seamless copper tubing is suitable for drinking water piping and heating systems due to its corrosion resistance and oxidation resistance, ensuring long-term stable water flow and heat transfer.

Advantages:

- High strength and pressure resistance

- No welded joints, reducing the risk of leakage

- Good corrosion resistance, suitable for long-term use

Inner Grooved Tube

Standards: ASTM B280, EN 12735-1

Applications:

- High-efficiency heat exchangers: Inner-grooved copper tubes are widely used in heat exchangers, condensers, and evaporators in air conditioning systems. The concave design increases the surface area, thereby improving heat transfer efficiency and maximizing heat exchange capacity within a given space.

- Refrigerant piping: Inner-grooved copper tubes are widely used in commercial and industrial refrigeration systems, such as large refrigerators and cold storage facilities, due to their improved heat exchange performance.

Advantages:

- Enhanced heat exchange efficiency

- Improved heat conduction during cooling or heating

- High corrosion resistance, adaptable to various environments

Copper Capillary Tube

Standard: ASTM B280

Applications:

- Refrigeration Systems: Capillary tubes are commonly used to regulate refrigerant flow, especially in residential air conditioning, refrigerator, and automotive air conditioning systems. Through their small diameter, capillary tubes limit the flow of refrigerant, controlling system pressure and temperature to maintain normal system operation.

- Temperature Control Systems: Capillary tubes are also used for pressure control in hydraulic and cooling systems.

Advantages:

- Precise control of refrigerant flow

- High pressure resistance, suitable for high temperature and high pressure environments

- Simple structure, low manufacturing cost

Fin Copper Tube

Standards: ASTM B280, ASTM B88

Applications:

- Evaporators and Condensers: Finned copper tubes are commonly used in evaporators, condensers, and other heat exchange equipment. By adding external fins, the surface area of the copper tube is increased, thereby enhancing heat exchange efficiency. They are widely used in air conditioning and refrigeration systems.

- Industrial Cooling Systems: In industrial applications, finned copper tubes are used in large cooling towers and heat exchangers to improve cooling efficiency and reduce energy consumption.

Advantages:

- Improved heat exchange efficiency, suitable for high-load operation

- Enhanced heat dissipation capacity through enlarged surface fins

- Suitable for high-temperature and high-pressure environments

Thin-Wall Copper Tube

Standards: ASTM B280, EN 12735-1

Applications:

- Lightweight HVAC Systems: Thin-wall copper tubes are commonly used in lightweight air conditioning and refrigeration systems, especially in applications requiring weight reduction, such as portable air conditioning units and automotive air conditioning systems.

- Precision Machinery and Electronic Equipment: Thin-wall copper tubes are also frequently used in heat sinks and heat exchangers for electronic equipment, especially in space-constrained environments.

Advantages:

- Lightweight, suitable for space-constrained applications

- Maintains high thermal conductivity, enhancing heat dissipation performance

- Saves materials, reducing costs

Global Market Trends Affecting Copper Tube Manufacturers (2025–2030)

Heat Pumps Replacing Traditional HVAC Systems

Europe and North America are rapidly adopting heat pumps to improve energy efficiency and reduce carbon emissions. This trend is driving demand for high-efficiency copper tubing with excellent thermal conductivity and corrosion resistance.

Liquid Cooling in Data Centers

The growth of cloud computing and AI has increased the need for advanced cooling. Microfin and inner-grooved tubes are now widely used in liquid cooling systems to enhance thermal efficiency and reduce energy consumption.

Expansion of New Energy Vehicles (NEVs)

Electric and hybrid vehicles require copper tubes for battery cooling and power electronics, demanding precise tolerances and high conductivity.

Global Shift Toward Eco-Friendly Copper

Suppliers producing copper tubes with recycled copper or low-carbon methods gain competitive advantage. Compliance with REACH, RoHS, and green manufacturing practices is increasingly valued.

Smart and Automated Production Technologies

AI-driven defect detection, robotic handling, and real-time monitoring are becoming standard, reducing material waste, improving precision, and enabling rapid response to custom orders.

Growing Demand for Customized, High-Performance Tubes

Across HVAC, refrigeration, industrial, and automotive applications, customers require tubes with specific diameters, wall thicknesses, and alloy compositions. Manufacturers with flexible production lines are better positioned to capture high-value segments.

How to Choose the Best Copper Tube Factory?

When choosing a suitable supplier/partner factory from among numerous copper tube manufacturers, it is recommended to focus on the following dimensions:

Product Variety and Specification Coverage

The factory can provide the types of copper tubes required for your project (e.g., seamless/welded tubes, capillary tubes, finned tubes, condenser/evaporator tubes, etc.), and do they support customized tube diameters, thicknesses, and alloy types.

Supply Chain Completeness

From smelting → extrusion → drawing → precision rolling → annealing → testing/quality control, a more complete supply chain allows for better control over raw material quality, processing precision, and consistency.

Production and Delivery Capabilities

Annual output, production capacity, number of production lines, ability to handle large-volume orders; supply stability, and delivery cycle.

Quality Control and Certification Capabilities

Does the factory comply with international standards (e.g., ASTM, EN, ISO, etc.)? Does it have strict testing/quality control procedures? Can it provide Material Reports (MTR) and batch tracking?

Geographical and Logistics Advantages

The factory's geographical location is advantageous for raw material sourcing, finished product transportation, and export customs clearance; proximity to ports or transportation hubs is a plus.

Customization and Service Capabilities

Does the supplier accept OEM/ODM? Can they produce according to customer drawings/samples? Do they offer flexible responses to customer needs and excellent after-sales service?

Sustainability and Environmental Compliance

In today's environment of green manufacturing and stringent environmental regulations, whether the copper tube supplier prioritizes recycling, reuse, waste disposal, and environmental compliance is also an important consideration for long-term cooperation.

Supplier Comparison

Copper Tube Factory Evaluation Table

|

Evaluation Criteria |

High Priority |

Mueller |

Wieland |

KME |

Luvata |

Jingliang |

|

HVAC copper pipe quality |

Five stars |

yes |

yes |

yes |

yes |

yes |

|

Precision heat-exchanger tubes |

Five stars |

yes |

yes |

yes |

One star |

yes |

|

Supply chain completeness |

Five stars |

Four stars |

Five stars |

Four stars |

Four stars |

Five stars |

|

Global delivery |

Five stars |

US-focused |

Strong |

Strong |

Strong |

Growing |

|

Cost competitiveness |

Four stars |

Medium |

Medium |

Medium |

Medium |

High |

|

Sustainability programs |

Four stars |

Strong |

Strongest |

Good |

Good |

Improving |

References / Sources

- Mordor Intelligence — “Copper Pipes And Tubes Market Size and Share”

- Future Market Insights — “Copper Tube Market 2025‑2035”

- MarketsandMarkets — “Copper Tubes Market by Type, Form, Application, Region — Global Forecast to 2030”

- Expert Market Research — “Copper Pipes and Tubes Market — Companies Overview & Trends”

- Grand View Research — “Copper Pipes and Tubes Market Size & Outlook to 2030”

Quick Link

Product Category

Content

- Global Demand for Copper Tubing Is Entering a New Growth Cycle

- Top 5 Copper Tube Manufacturers in 2025

- Key Standards to Evaluate Copper Tube Manufacturers

- Types of Copper Tubes and Their Applications

- Global Market Trends Affecting Copper Tube Manufacturers (2025–2030)

- How to Choose the Best Copper Tube Factory?

- Supplier Comparison

- References / Sources

- Quick Link

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文