Why Copper Capillary Tubes Are Essential for Refrigeration Systems

Refrigeration systems are essential in modern-day life, from preserving food and medicine to maintaining the comfort of our homes and workplaces. One of the key components that ensure the efficient operation of these systems is the capillary tube. Among various materials used for capillary tubes, copper has proven to be an ideal choice due to its unique properties.

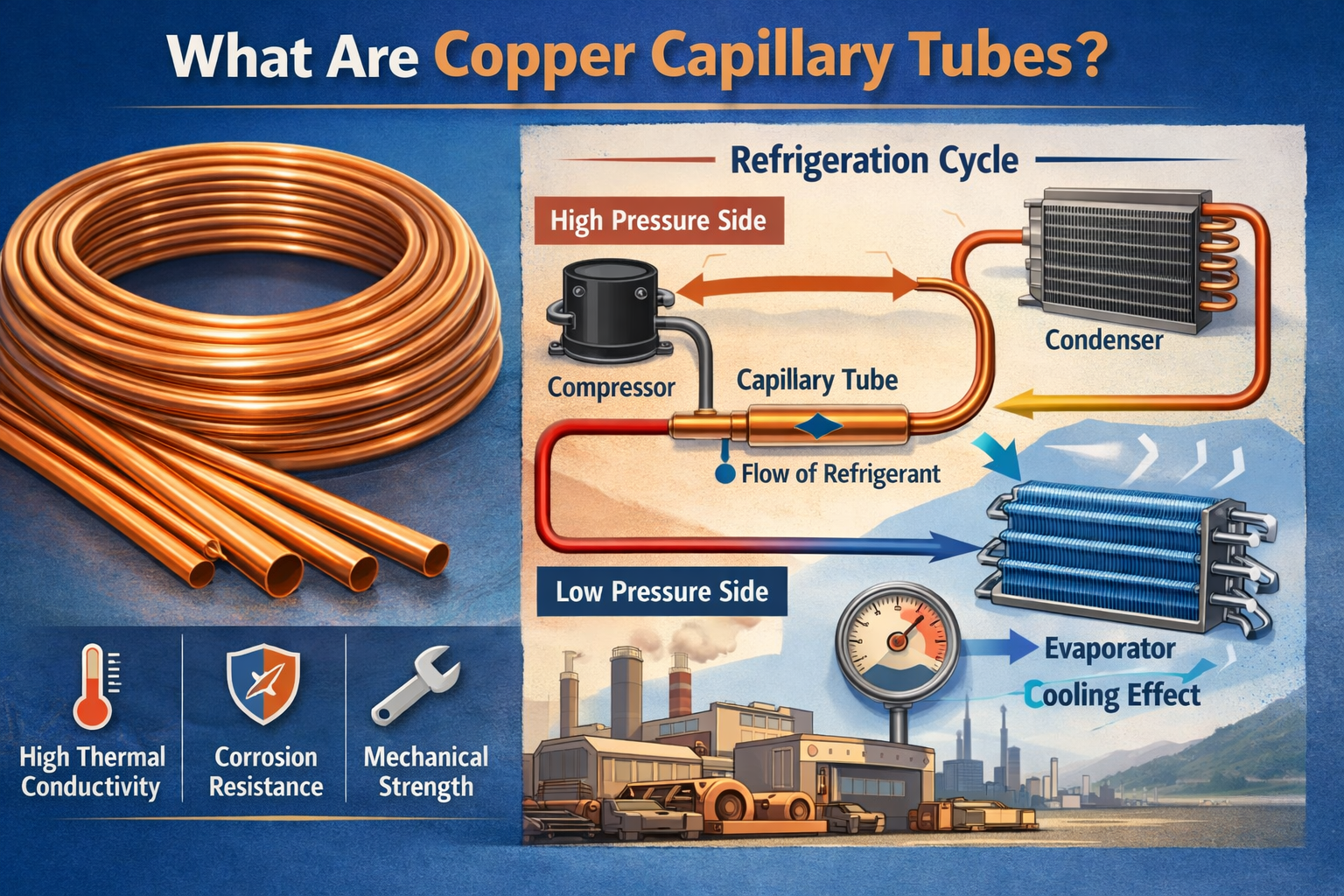

What Are Copper Capillary Tubes?

A capillary tube is a small, narrow tube that serves as a critical component in refrigeration systems, especially in the expansion valve section of the refrigeration cycle. The tube works by controlling the flow of refrigerant from the high-pressure side to the low-pressure side of the system. By reducing the pressure of the refrigerant as it flows through the tube, the refrigerant expands and cools, which is a vital part of the cooling process.

Copper is one of the most commonly used materials for capillary tubes due to its excellent thermal conductivity, resistance to corrosion, and mechanical strength. These qualities make copper an ideal material for creating reliable, long-lasting capillary tubes that can withstand the demands of refrigeration systems. As a result, many manufacturers rely on copper tube factory to produce high-quality copper capillary tubes to meet industry standards.

(This image was generated by AI.)

The Role of Copper Capillary Tubes in Refrigeration Systems

In refrigeration systems, the capillary tube plays a pivotal role in regulating the flow of refrigerant. The refrigerant enters the capillary tube from the condenser, where it is in a high-pressure, high-temperature state. As the refrigerant flows through the narrow capillary tube, its pressure drops, causing it to expand and cool. This low-pressure, cold refrigerant then enters the evaporator, where it absorbs heat from the surrounding environment, cooling the area or substance within the refrigeration system.

The copper capillary tube, due to its precise construction and material properties, ensures that the refrigerant flows at the optimal rate to facilitate efficient heat transfer. Any disruption in this flow can lead to reduced efficiency, poor cooling performance, and higher energy consumption.

Advantages of Copper for Capillary Tubes

Excellent Thermal Conductivity

Copper is known for its excellent thermal conductivity, which allows it to transfer heat efficiently. In refrigeration systems, the capillary tube must quickly and efficiently transport refrigerant from the high-pressure side to the low-pressure side. Copper’s thermal conductivity ensures that the refrigerant can undergo the pressure drop process smoothly, facilitating the desired cooling effect in the system. This efficient thermal transfer also contributes to the overall energy efficiency of the system.

Corrosion Resistance

Refrigeration systems often operate in harsh environments, subjecting components to extreme temperatures, moisture, and chemical exposure. Copper is highly resistant to corrosion, ensuring that capillary tubes made from copper maintain their integrity and performance over time. Unlike other metals that can degrade due to corrosion, copper capillary tubes are durable and can withstand prolonged exposure to the conditions within refrigeration systems.

Mechanical Strength and Durability

Copper is a strong and flexible material, making it ideal for manufacturing capillary tubes that must endure high-pressure conditions. The mechanical strength of copper ensures that the capillary tube remains intact and does not fail under the stresses placed on it by the refrigeration cycle. Additionally, copper’s flexibility allows it to be easily shaped and manufactured into precise dimensions, making it suitable for a wide range of applications in refrigeration systems.

Thermal Expansion

Copper has a relatively low coefficient of thermal expansion, meaning it does not expand or contract significantly with changes in temperature. This stability ensures that copper capillary tubes maintain their performance over a wide range of operating temperatures, which is essential in refrigeration systems that are constantly cycling between high and low temperatures.

Ease of Manufacturing

Copper is a versatile material that can be easily drawn into thin tubes with precise dimensions. The manufacturing process for copper capillary tubes is straightforward, allowing for high-quality production at scale. This ease of manufacturing ensures that copper capillary tubes are widely available and cost-effective, making them a practical choice for refrigeration systems across various industries. Many companies source these tubes directly from reliable copper tube factories, ensuring consistency in quality and performance.

Comparison of Copper, Aluminum, and Stainless Steel for Capillary Tubes

To better understand why copper is the preferred material for capillary tubes in refrigeration systems, here is a comparison table highlighting the key characteristics of copper, aluminum, and stainless steel:

| Property | Copper | Aluminum | Stainless Steel |

| Thermal Conductivity | Excellent | Moderate | Low |

| Corrosion Resistance | High | Moderate | Excellent |

| Mechanical Strength | Strong and Flexible | Moderate | High |

| Thermal Expansion | Low | Moderate | Low |

| Manufacturing Ease | Easy to Manufacture | Easy but less precise | Difficult and expensive |

| Cost | Moderate | Low | High |

As shown in the table, copper excels in thermal conductivity and corrosion resistance, while also being easy to manufacture. Aluminum, although cheaper, lacks the same level of thermal conductivity and strength, making it less reliable for high-performance refrigeration systems. On the other hand, stainless steel is more durable but significantly more expensive and difficult to work with for capillary tubes, making it less ideal for most applications.

Applications of Copper Capillary Tubes in Different Types of Refrigeration Systems

Copper capillary tubes are found in many different types of refrigeration systems, including those used in home appliances, commercial refrigeration, and industrial cooling systems. Below are some of the key areas where copper capillary tubes play a vital role.

Residential Refrigerators and Freezers

In residential refrigerators and freezers, copper capillary tubes are used to control the flow of refrigerant between the condenser and evaporator. The reliable and efficient operation of these tubes is essential for maintaining the cooling performance of these appliances. Copper’s corrosion resistance ensures that these systems continue to operate effectively over extended periods.

Air Conditioning Systems

Air conditioning systems use refrigeration cycles to cool indoor spaces. Copper capillary tubes help regulate the flow of refrigerant in these systems, ensuring that the air conditioning units operate efficiently and provide consistent cooling. The thermal conductivity of copper helps the system achieve the desired cooling effect while maintaining energy efficiency.

Commercial Refrigeration Units

Commercial refrigeration units, such as those used in supermarkets, restaurants, and warehouses, rely on copper capillary tubes for optimal performance. These systems often operate under heavy-duty conditions, requiring highly durable and reliable components. Copper’s corrosion resistance and mechanical strength make it an ideal material for capillary tubes in commercial refrigeration systems.

Industrial Refrigeration Systems

In industrial refrigeration systems, copper capillary tubes are used to regulate the flow of refrigerant in large-scale cooling applications. These systems require components that can handle high volumes of refrigerant and operate in demanding conditions. Copper’s strength, thermal conductivity, and resistance to corrosion ensure that these systems run efficiently and reliably.

Why Choose Copper Over Other Materials?

While there are other materials available for capillary tubes, such as aluminum and stainless steel, copper remains the preferred choice for refrigeration systems. Aluminum, for example, may be lighter but lacks the same level of thermal conductivity and mechanical strength as copper. Stainless steel is strong and resistant to corrosion, but it is more expensive and harder to manufacture into the precise dimensions required for capillary tubes.

Copper offers a balanced combination of excellent thermal performance, durability, corrosion resistance, and ease of manufacturing. These advantages make copper capillary tubes the material of choice for refrigeration systems worldwide. Manufacturers often rely on trusted copper tube factory to provide high-quality tubes that meet the necessary specifications.

The Importance of Proper Maintenance

Although copper capillary tubes are highly durable and resistant to corrosion, they still require proper maintenance to ensure the continued efficiency of the refrigeration system. Regular inspection of the capillary tube for any signs of damage, such as kinks or blockages, is essential. Additionally, ensuring that the refrigerant charge is at the correct level is crucial to prevent overloading or underperformance of the capillary tube.

Proper installation is also important, as improper routing of the capillary tube or using a tube with incorrect dimensions can lead to system inefficiencies and failures. Ensuring that the copper capillary tube is installed correctly and maintained regularly will help prolong the lifespan of the refrigeration system and enhance its overall performance.

Product Category

Content

- What Are Copper Capillary Tubes?

- The Role of Copper Capillary Tubes in Refrigeration Systems

- Advantages of Copper for Capillary Tubes

- Comparison of Copper, Aluminum, and Stainless Steel for Capillary Tubes

- Applications of Copper Capillary Tubes in Different Types of Refrigeration Systems

- Why Choose Copper Over Other Materials?

- The Importance of Proper Maintenance

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文