Fin Copper Tubes vs. Aluminum Tubes: Which Is Better for Heat Transfer?

In the world of heat exchangers, air conditioning systems, refrigeration units, and other thermal management applications, the choice of materials for the tubes that facilitate heat transfer is crucial. Copper and aluminum are two of the most commonly used metals in these systems, particularly when it comes to fins and tubes that enhance heat exchange efficiency. However, when it comes to performance, the question arises: Which is better for heat transfer—Fin Copper Tubes or Aluminum Tubes?

Understanding Heat Transfer and Tube Materials

Before delving into the differences between copper and aluminum tubes, it’s important to understand the basic principles of heat transfer in the context of thermal systems. Heat transfer involves the movement of thermal energy from one substance to another, typically from a hotter area to a cooler one. In heat exchangers and similar applications, metal tubes and fins are used to efficiently transfer heat from the fluid inside the tubes to the surrounding air or another fluid.

The materials used for these tubes and fins need to have high thermal conductivity to maximize the heat transfer process. Thermal conductivity is the ability of a material to conduct heat, and it plays a key role in how efficiently heat is transferred.

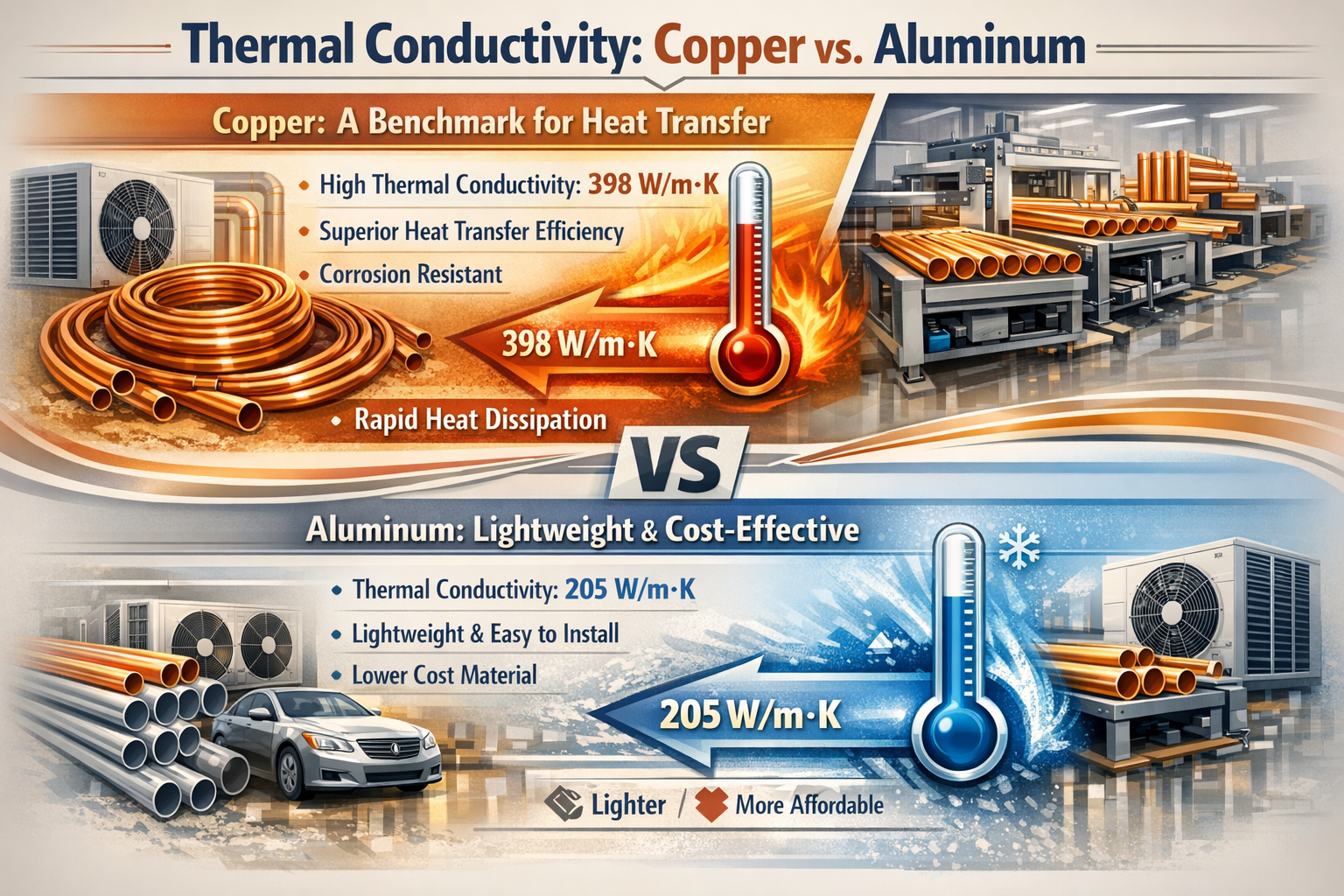

Thermal Conductivity: Copper vs. Aluminum

Copper: A Benchmark for Heat Transfer

Copper has long been considered the gold standard when it comes to heat transfer efficiency. It is a highly conductive material, with a thermal conductivity of approximately 398 W/m·K, which is significantly higher than most metals. This means that copper tubes can quickly transfer heat from one place to another, making them ideal for high-performance applications where fast heat dissipation is crucial, such as in refrigeration and air conditioning systems.

When sourcing copper tubes, choosing a reliable copper tube factory can ensure that the tubes meet high standards for thermal conductivity and quality. The precision of manufacturing in a copper tube factory can significantly affect the performance and longevity of the tubes, ensuring they operate efficiently over time.

In addition to its high thermal conductivity, copper is also resistant to corrosion, particularly in low humidity environments. This resistance ensures that copper tubes maintain their heat transfer efficiency over a longer period, which is critical in applications where consistent performance is essential.

Aluminum: Lightweight and Cost-Effective

Aluminum, on the other hand, has a lower thermal conductivity compared to copper, with a value of approximately 205 W/m·K. While this is still a good conductor of heat, it is only about half as effective as copper in terms of heat transfer efficiency. Despite this, aluminum has become a popular choice in heat exchange systems due to its several advantages.

One of the key benefits of aluminum is its lightweight nature. Aluminum is much lighter than copper, making it easier to handle, transport, and install. This can be particularly advantageous in large systems or applications where weight reduction is important, such as in automotive air conditioning systems or large-scale HVAC installations.

Aluminum is also significantly more cost-effective than copper. For projects with budget constraints or those that require large quantities of material, aluminum provides a more affordable option while still offering acceptable heat transfer performance. Furthermore, aluminum is more abundant than copper, which contributes to its lower cost.

(This image was generated by AI.)

Comparing the Properties of Copper and Aluminum Tubes

To clearly visualize the differences between copper and aluminum tubes, here’s a comparison table highlighting their key attributes:

| Property | Copper Tubes | Aluminum Tubes |

| Thermal Conductivity | 398 W/m·K | 205 W/m·K |

| Corrosion Resistance | High (particularly in low humidity) | Moderate (requires coatings) |

| Weight |

Heavier |

Lighter |

| Cost | Higher | Lower |

| Durability | Long-lasting, especially in harsh environments | Susceptible to corrosion in certain conditions |

| Common Applications | Refrigeration, HVAC, automotive, aerospace | HVAC, automotive, solar heat collectors |

| Environmental Impact | Can be recycled | Highly recyclable, lower embodied energy |

This table highlights the distinct differences between copper and aluminum tubes, with copper offering superior heat transfer but at a higher cost, while aluminum is more lightweight and cost-effective but comes with trade-offs in performance and durability.

Durability and Corrosion Resistance

Copper: Long-Lasting Performance

Copper tubes are highly durable and offer excellent resistance to corrosion, especially when used in environments with low humidity or controlled conditions. In applications where durability and longevity are essential, such as in refrigeration systems or outdoor HVAC systems, copper’s resistance to corrosion can lead to a longer lifespan and reduced maintenance costs.

When sourcing from a copper tube factory, it is crucial to ensure that the manufacturing processes and materials meet the highest standards to maximize corrosion resistance. High-quality copper tubes from a reputable factory can provide long-term performance in even the most demanding applications.

Copper also performs well in both high and low-temperature environments, maintaining its heat transfer properties even under extreme conditions. This makes it an ideal choice for systems that need to operate efficiently over long periods, including those used in industrial or commercial settings.

Aluminum: Susceptibility to Corrosion

While aluminum is also resistant to corrosion, it is not as resistant as copper, particularly in environments exposed to moisture or saltwater. Over time, aluminum can develop an oxide layer on its surface, which can help protect it from corrosion to some extent. However, this protective layer can be compromised if the aluminum is exposed to harsh chemicals or extreme environmental conditions.

In applications where aluminum tubes are used, additional protective coatings or treatments may be required to prevent corrosion, which can increase maintenance costs and reduce the material's overall lifespan. Despite these challenges, aluminum tubes are still commonly used in less demanding environments or where the benefits of light weight and cost outweigh the need for extreme durability.

Cost Considerations

One of the most significant factors when choosing between copper and aluminum tubes is cost. Copper is generally more expensive than aluminum, both in terms of raw material costs and the overall manufacturing process. However, copper’s high thermal conductivity and durability can make it a more cost-effective choice in the long run for certain applications, particularly when considering the reduced need for repairs or replacements over time.

Aluminum, on the other hand, offers a more budget-friendly solution for projects where initial costs need to be minimized. While aluminum tubes may not offer the same heat transfer performance or durability as copper, they are suitable for many applications where these factors are less critical.

Applications in Industry

Copper Tubes

Copper tubes are commonly used in high-performance heat exchange applications, including:

1. Refrigeration and Air Conditioning: Copper’s high thermal conductivity makes it an ideal choice for cooling systems, such as air conditioners, refrigerators, and heat pumps. Copper tubes allow for rapid heat transfer, ensuring efficient cooling in these systems.

2. Industrial Heat Exchangers: In industrial settings, copper tubes are often used in heat exchangers where large amounts of heat need to be transferred quickly and efficiently. These include applications in power plants, chemical processing, and petroleum refining.

3. Automotive and Aerospace: Copper’s heat transfer properties are also essential in automotive and aerospace applications, where heat management plays a critical role in engine cooling and thermal regulation.

When purchasing copper tubes, sourcing them from a copper tube factory ensures that the tubes meet high manufacturing standards and can perform effectively in demanding industrial applications.

Aluminum Tubes

Aluminum tubes, while not as effective as copper in terms of heat transfer, are widely used in applications where weight and cost are more important:

1. HVAC Systems: In residential and commercial HVAC systems, aluminum tubes are commonly used in heat exchangers, particularly when cost savings and weight reduction are priorities.

2. Automotive Applications: Aluminum is commonly used in automotive air conditioning and cooling systems due to its lightweight nature, making it a popular choice in vehicle design where reducing weight is important for fuel efficiency.

3. Solar Heat Collectors: Aluminum tubes are often used in solar heat collectors, where cost is a significant consideration, and aluminum’s relatively lower thermal conductivity is sufficient for effective heat collection.

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文