Copper Tube Industry Segmentation Report: How Are Niche Markets Reshaping the Competitive Landscape?

Subtitle: While traditional copper tubes grapple with price wars, segments like semiconductor-grade oxygen-free copper tubes and ultra-thin wall tubes for new energy vehicles achieve 30%+ gross margins—how do these niche products, representing less than 5% of total industry capacity, drive 35% of total profits?

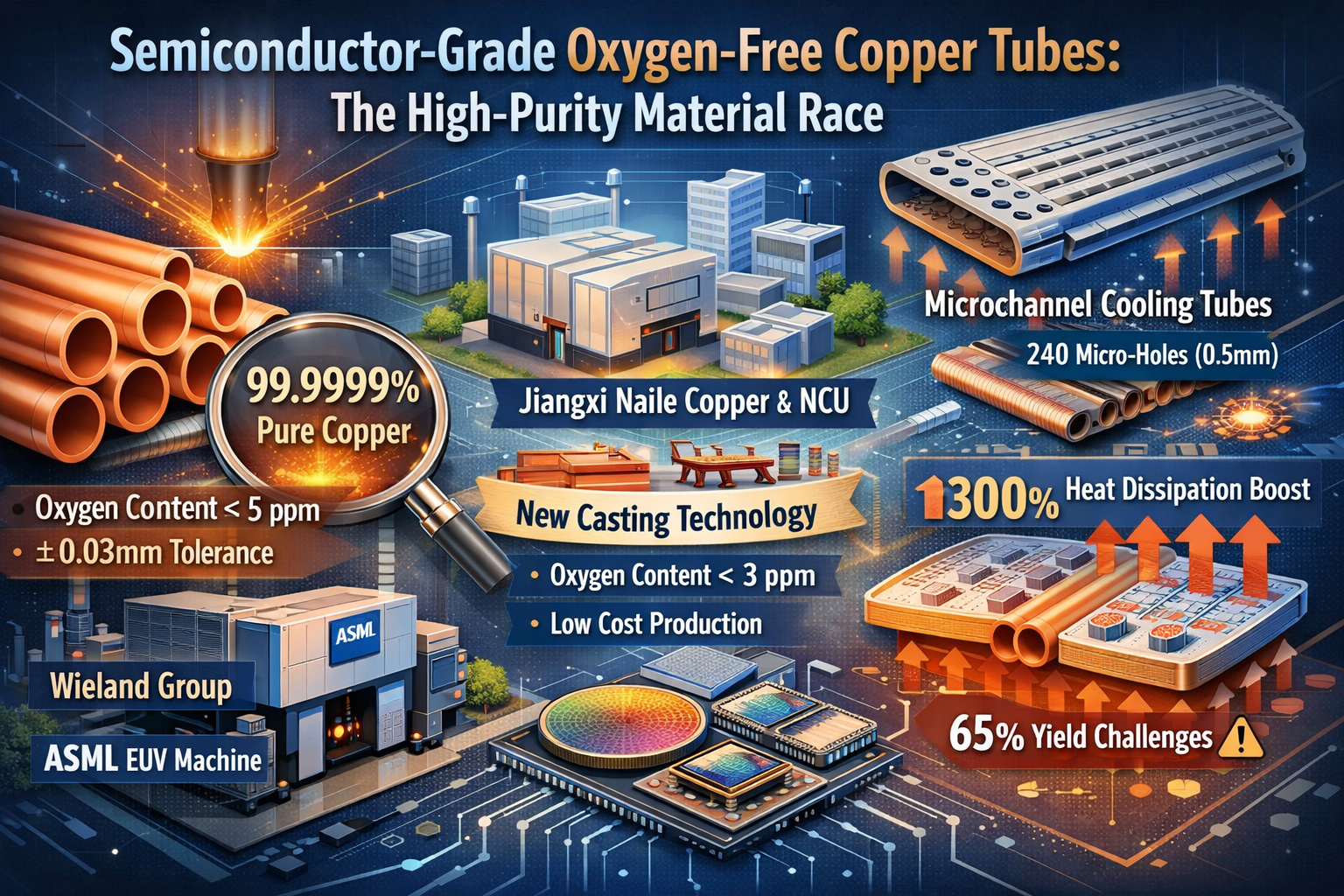

Semiconductor-Grade Oxygen-Free Copper Tubes: The High-Purity Material Race

The upgrade of semiconductor manufacturing equipment demands extreme purity standards for copper tubes. By 2025, semiconductor-grade oxygen-free copper tubes require oxygen content ≤5ppm and wall thickness tolerance of ±0.03mm. Global production capacity for such products is less than 10,000 tons, yet they capture over 60% of high-end market profits. For example, the cooling system copper tubes in ASML’s EUV lithography machines, supplied exclusively by Germany’s Wieland Group, use electron beam floating zone melting technology to achieve 99.9999% copper purity, commanding prices 80 times higher than ordinary copper tubes.

Breakthroughs in cost-effective alternatives are emerging. Jiangxi Naile Copper, in collaboration with Nanchang University, developed an "ultra-low oxygen split horizontal continuous casting method" that controls oxygen content below 3ppm at one-eighth the cost of imported vacuum methods. This innovation has entered the supply chain for SMIC’s 14nm production lines. More advanced applications include wafer-level cooling tubes with microchannel designs (e.g., 240 micro-holes of 0.5mm diameter) to enhance heat dissipation efficiency by 300%, though yield rates remain a challenge at 65%.

(This image was generated by AI.)

Table: Semiconductor-Grade Copper Tubes – Technical Parameters and Market Landscape (2025)

| Metric | Global Leading Standard | Domestic Leading Standard | Gap Analysis |

| Oxygen Content |

≤1ppm (ASML standard) |

≤3ppm (SMIC standard) | 2x purity difference |

| Surface Roughness |

Ra ≤0.4μm |

Ra ≤0.8μm | 2x precision gap |

| Price Range |

$300,000–500,000/ton |

$80,000–120,000/ton | 4–6x price difference |

| Global Market Share |

Europe: 68% |

China: 12% | 5x market share gap |

EV Ultra-Thin Wall Copper Tubes: Lightweighting and Thermal Management Trade-Offs

The rise of 800V high-voltage platforms in electric vehicles has intensified demand for ultra-thin wall copper tubes (wall thickness ≤0.25mm). In 2025, this segment grew by 200% year-on-year, with the global market exceeding $7 billion. BYD’s "Blade Battery" uses multi-channel microporous copper tubes laser-welded to 0.2mm thickness, increasing battery pack volume utilization to 72%. However, welding yield remains a bottleneck, with top copper tube factory achieving only 85%.

Material innovation is key. Japan’s Mitsubishi Materials developed aluminum-core composite copper tubes using explosion welding to bond copper and aluminum, reducing weight by 40% and cost by 30%. These are used in Toyota’s solid-state battery thermal management systems. Domestic players like Hailiang Co. focus on copper-graphene composites with thermal conductivity of 500 W/m·K (1.5x pure copper), though mass production challenges persist.

Process advancements further demonstrate technical prowess. Guangdong Longfeng’s gradient wall thickness technology controls variations within ±0.05mm across tube sections, adapting to irregular battery pack spaces and improving heat dissipation efficiency by 25%. Such products sell for 10x the price of ordinary copper tubes, with gross margins exceeding 40%.

Data Center Liquid Cooling Copper Tubes: The "Cooling Revolution" in Digital Infrastructure

AI computing demands are driving growth in liquid cooling copper tubes for data centers. By 2025, global demand reached 150,000 tons, growing at 35% annually. Nvidia’s GB200 chip uses immersion cooling systems requiring copper tubes with 50% higher corrosion resistance and a lifespan of over 10 years. U.S.-based Materion’s nanocoating technology enables stable operation in coolants with pH levels of 3–11, priced 15x higher than standard tubes.

The competition revolves around precision and intelligence. Google’s data centers use smart copper tubes embedded with fiber optic sensors to monitor temperature and flow in real-time, reducing PUE (Power Usage Effectiveness) below 1.1. Domestic company Guangdong Longfeng employs 5G and digital twin systems for full-process monitoring, cutting defect rates to 0.3‰.

Cost optimization is critical. Zhejiang Hailiang’s stainsteel-lined composite copper tubes use stainless steel for corrosion resistance and copper for heat conduction, costing 30% less than all-copper tubes but sacrificing 15% thermal efficiency—mainly for mid- to low-end data centers.

Aerospace-Grade Copper Tubes: Reliability in Extreme Environments

Copper tubes for commercial aircraft hydraulic systems must operate between -55°C and 200°C. Boeing 787’s high-strength pressure-resistant copper tubes withstand burst pressures of 45MPa (3x ordinary tubes), priced 20x higher than automotive-grade tubes. France’s Figeac Group uses spinning technology to increase tensile strength to 400MPa for landing gear hydraulic pipelines.

New materials are pushing boundaries. SpaceX’s Starship uses copper-silver-zirconium alloy tubes produced via vacuum melting and cold rolling, maintaining thermal conductivity of 350 W/m·K while increasing strength by 50%. However, costs reach $1,000/kg, limiting use to aerospace.

Testing standards create high barriers. U.S. Parker aerospace tubes must pass 2,000-hour salt spray tests and 1,500 pressure pulse cycles, with defect rates below 0.1‰—a standard met by only five companies globally.

Niche Markets as New Profit Engines

The segmentation of the copper tube industry reveals a shift from homogeneous competition to technology-driven differentiation. While traditional markets face margin compression, high-end segments like semiconductor, EV, and data center tubes leverage innovation to capture disproportionate value. For companies, success hinges on R&D depth, customization capabilities, and binding partnerships with top-tier clients. As one industry expert notes, "In niche markets, scoring 90 points may not ensure survival; achieving 99 points is necessary for profitability".

Product Category

Content

- Semiconductor-Grade Oxygen-Free Copper Tubes: The High-Purity Material Race

- EV Ultra-Thin Wall Copper Tubes: Lightweighting and Thermal Management Trade-Offs

- Data Center Liquid Cooling Copper Tubes: The "Cooling Revolution" in Digital Infrastructure

- Aerospace-Grade Copper Tubes: Reliability in Extreme Environments

- Niche Markets as New Profit Engines

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文