The Ultimate Guide to TP2 Copper Tubes: Properties, Applications, and Industry Standards

Part 1: Introduction to TP2 Copper Tubes

1.1 Defining TP2 Copper: The Industry Standard

TP2 Copper is a phosphorus-deoxidized copper with a high residual phosphorus content. In the realm of metallurgy, it is classified under the Chinese standard GB/T 1527, which is functionally equivalent to the internationally recognized ASTM C12200 (Cu-DHP).

The “P” in TP2 stands for Phosphorus, which is added during the smelting process to remove oxygen. By “deoxidizing” the copper, manufacturers create a material that is significantly more reliable for industrial applications than standard pure copper, particularly when heat and welding are involved.

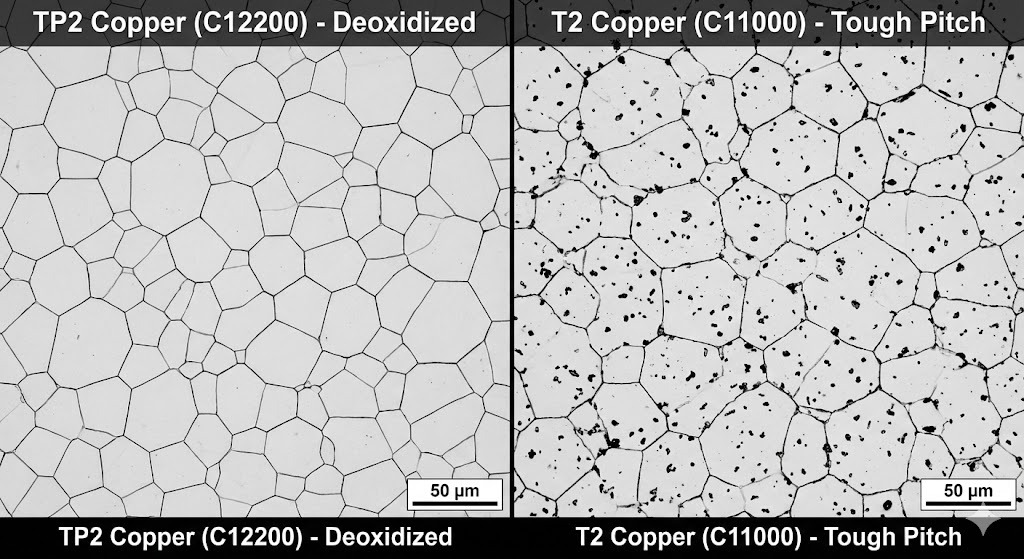

1.2 The Significance: Why Deoxidized Copper Matters

The primary significance of TP2 copper lies in its weldability. Traditional “tough pitch” copper (like T2) contains trace amounts of oxygen. When T2 is heated or welded in a hydrogen-rich atmosphere, it suffers from “hydrogen embrittlement,” leading to microscopic cracks and structural failure.

TP2 solves this problem. Because the phosphorus has already bonded with and removed the oxygen, TP2 copper tubes can be brazed and welded safely, ensuring leak-proof joints. This makes it the “gold standard” for systems that must hold high-pressure gases or liquids for decades.

1.3 TP2 vs. TP1: A Brief Comparison

While both are phosphorus-deoxidized, the choice between them often comes down to a trade-off between thermal/electrical conductivity and joining reliability:

- TP1 (Low Phosphorus): Contains less phosphorus (0.005% to 0.012%). It offers higher conductivity but is slightly more sensitive during complex welding processes.

- TP2 (High Phosphorus): Contains more phosphorus (0.013% to 0.050%). It is the preferred choice for the HVAC and refrigeration industries because its superior welding performance outweighs the slight decrease in conductivity.

1.4 Common Uses and Industries

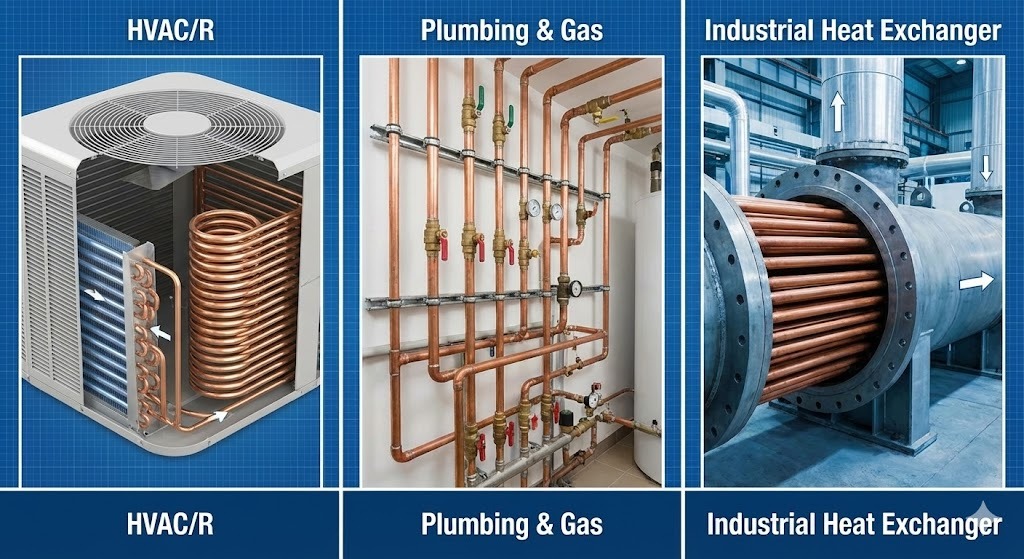

TP2 copper tubes are the “circulatory system” of modern infrastructure. Due to their unique blend of corrosion resistance and thermal efficiency, they are indispensable in:

- HVAC/R (Heating, Ventilation, Air Conditioning, and Refrigeration): Used for refrigerant lines and evaporator/condenser coils.

- Plumbing & Gas: Safe transport of potable water and medical gases.

- Power & Energy: Heat exchangers in power plants and cooling systems for renewable energy hardware.

- Automotive: Increasingly used in the thermal management systems of Electric Vehicle (EV) batteries.

Part 2: Standards and Specifications

When purchasing or specifying TP2 copper tubes, it is vital to use the correct international nomenclature to ensure quality.

2.1 Common Industry Standards

| Region | Standard | Designation |

|---|---|---|

| China | GB/T 1527 | TP2 |

| International (ISO) | ISO 1190 | Cu-DHP |

| USA (ASTM) | ASTM B280 / B68 / B75 | C12200 |

| Europe (EN) | EN 12735 / EN 1057 | CW024A |

| Japan (JIS) | JIS H3300 | C1220 |

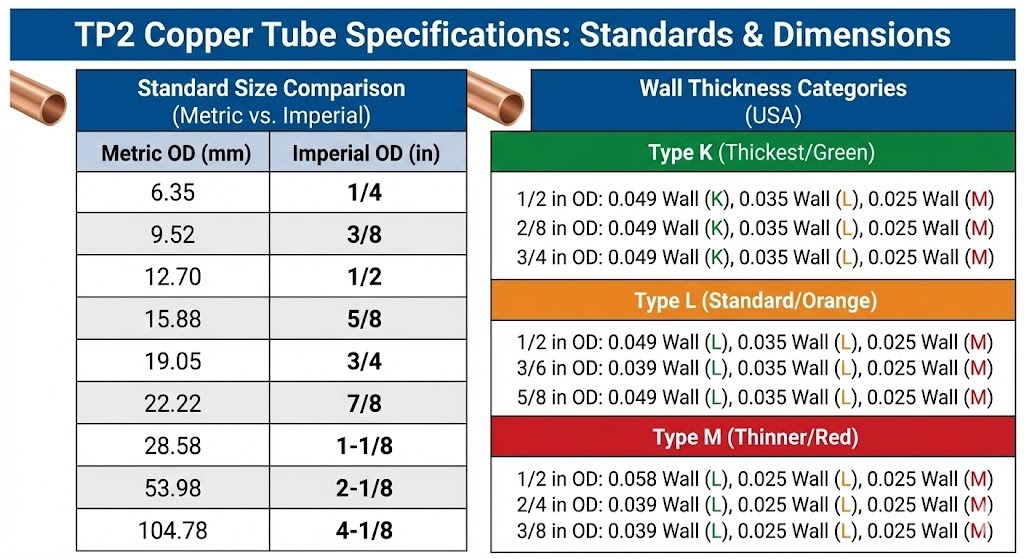

2.2 Dimensional Specifications

TP2 tubes are available in a vast range of sizes, but they are generally categorized by:

- Outer Diameter (OD): Typically ranges from 2 mm to over 200 mm .

- Wall Thickness: From “Ultra-thin” (0.2 mm) to “Heavy-wall” (5 mm+ for high-pressure industrial use).

- Tolerances: Precision tubes often have a diameter tolerance of +/- 0.02 mm to ensure airtight fits with mechanical couplings.

Part 3: Chemical Composition and Physical Properties

3.1 Chemical Composition: The Role of Phosphorus

The performance of TP2 copper is dictated by its high purity and the precise control of phosphorus. According to standard specifications (such as GB/T 5231 or ASTM C12200), the composition is strictly regulated:

| Element | Content (%) | Function |

|---|---|---|

| Copper (Cu + Ag) | >=99.90% | Provides the base for high conductivity and corrosion resistance. |

| Phosphorus § | 0.013% to 0.050% | Acts as the deoxidizing agent; prevents hydrogen embrittlement. |

| Impurities | <=0.1% | Minimized to ensure material consistency and ductility. |

Why the 0.013% - 0.050% Range?

If phosphorus is below 0.013%, deoxidation may be incomplete, risking brittle joints during welding. If it exceeds 0.050%, the thermal and electrical conductivity drops significantly, reducing the efficiency of heat exchangers.

3.2 Physical and Mechanical Properties

TP2 copper tubes are prized for their “soft” strength—they are strong enough to hold high pressures but ductile enough to be bent into complex coils without cracking.

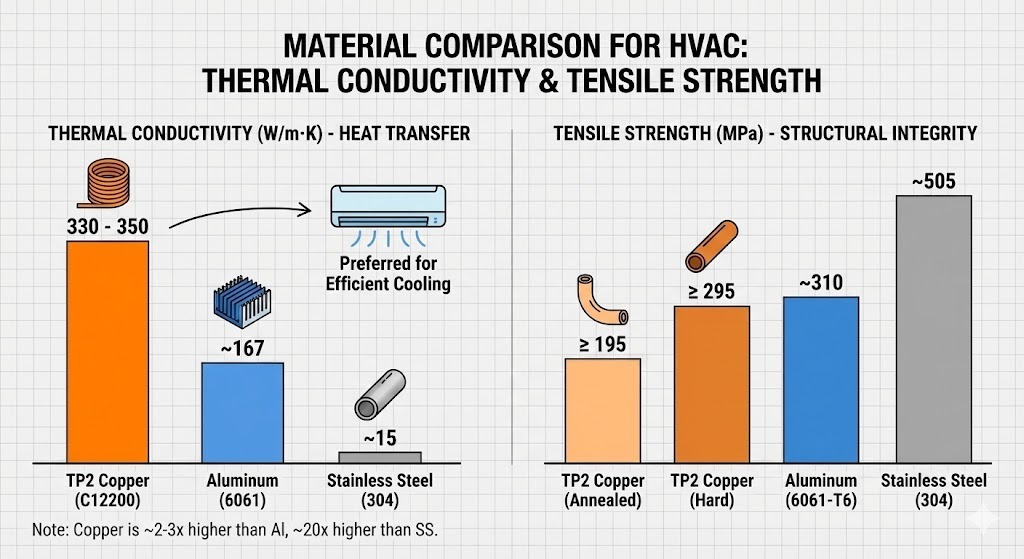

A. Tensile Strength and Yield Strength

Tensile strength depends on the “temper” (hardness) of the tube:

- Soft (Annealed, M): >= 195 MPa. Highly flexible, ideal for hand-bending and tight coils.

- Hard (H): >= 295 MPa. Rigid and strong, used for straight piping runs in plumbing and industrial lines.

- Yield Strength: Typically ranges from 60 - 150 MPa depending on the temper.

B. Elongation

This measures the material’s ability to stretch before breaking. TP2 copper typically has an elongation rate of >= 35% - 40% (in annealed state). This high ductility is what allows the tube to be expanded, flared, or swaged without fracturing.

C. Thermal Conductivity

While the addition of phosphorus reduces conductivity compared to pure copper, TP2 still remains a leader among metals:

- Thermal Conductivity: Approximately 330 - 350 W/(m·K) at 20°C.

- Note: This is roughly 2-3 times higher than aluminum and 20 times higher than stainless steel, which is why it is the preferred material for air conditioner evaporators.

D. Electrical Conductivity

- Electrical Conductivity: >= 70% - 80% IACS(International Annealed Copper Standard).

- While lower than the 100% IACS of oxygen-free copper (C10200), it is more than sufficient for grounding and heat-sync applications where welding is also required.

3.3 Physical Constant Summary Table

| Property | Value |

|---|---|

| Density | 8.94 g/cm3 |

| Melting Point | 1083°C |

| Coefficient of Thermal Expansion | 17.7 x 10^-6 /K |

| Modulus of Elasticity | 115 GPa |

Part 4: Manufacturing Process of TP2 Copper Tubes

The production of TP2 copper tubes is a journey from high-heat smelting to high-precision cold working. Most premium TP2 tubes are produced as seamless tubes, which eliminates the risk of weld-seam failure.

4.1 Step-by-Step Production Flow

- Melting and Casting (The Deoxidation Phase):

High-purity cathode copper is melted in an induction furnace. During this stage, phosphorus is added to the molten bath. This is the critical moment where oxygen is removed, transforming the batch into TP2 copper. The molten metal is then cast into solid cylindrical billets. - Extrusion (Hot Working):

The copper billet is heated and forced through a die under massive pressure to create a thick-walled hollow shell. This “hot working” breaks down the cast grain structure, making the metal tougher and more uniform. - Cold Drawing and Rolling:

To achieve the final diameter and wall thickness, the tube undergoes multiple stages of Cold Drawing or Cold Rolling (Pilgering). The tube is pulled through progressively smaller dies. This process increases the strength of the metal through “work hardening.” - Bright Annealing:

Cold drawing makes the copper hard and brittle. To restore the ductility required for bending and flaring (especially for “Soft” or “Half-hard” tempers), the tubes are heated in a controlled-atmosphere furnace (usually nitrogen or hydrogen) to prevent oxidation. This results in a clean, “bright” surface. - Finishing and Cleaning:

The tubes are cut to length or coiled. For HVAC applications, the interior must be surgically clean, as any residual oil or dust could damage a compressor.

4.2 Quality Control Measures

To ensure TP2 tubes meet international standards like ASTM B280, manufacturers employ rigorous testing:

- Eddy Current Testing: A non-destructive test that uses electromagnetic fields to detect invisible cracks or pits in the tube wall.

- Hydrostatic Testing: The tube is filled with high-pressure fluid to ensure it can withstand the pressures of modern refrigerants (like R-410A or R-32).

- Dimensional Inspection: Precision calipers and laser gauges ensure the wall thickness is uniform—critical for maintaining pressure ratings.

Part 5: Key Features and Benefits of TP2 Copper Tubes

Why is TP2 the “industry darling”? Its benefits extend beyond simple conductivity.

5.1 Superior Corrosion Resistance

TP2 copper forms a natural, protective patina layer when exposed to the elements. Unlike steel, it does not rust. In plumbing and HVAC, this means the tube will not thin out or develop “pinhole leaks” easily over a 20-30 year lifespan.

5.2 High Thermal Efficiency

As noted in the properties section, TP2’s thermal conductivity is exceptional. In a heat exchanger, this allows for faster heat transfer in a smaller footprint, enabling the design of compact, high-efficiency air conditioning units.

5.3 Excellent “Joinability”

Because TP2 is phosphorus-deoxidized, it is the most user-friendly copper for brazing and soldering. Technicians can join tubes quickly using a torch without worrying about the metal becoming brittle or the joint failing under vibration.

5.4 Ductility and Formability

TP2 copper can be easily bent, expanded, or “swaged” without specialized heavy machinery. This flexibility is vital for installing refrigerant lines in tight spaces or creating complex evaporator coils.

5.5 100% Recyclability

Copper is a “permanent” material. TP2 copper tubes can be recycled indefinitely without any loss in performance. In an era of ESG (Environmental, Social, and Governance) goals, using copper is a sustainable choice for green building certifications.

Part 6: Applications of TP2 Copper Tubes Across Industries

6.1 HVAC and Refrigeration: The Heart of the System

This is the most dominant sector for TP2 copper. Modern refrigerants operate at high pressures, requiring the seamless reliability that TP2 provides.

- Air Conditioning & Heat Pumps: Used for connecting indoor and outdoor units. TP2’s ductility allows it to be flared and connected to valves with zero leaks.

- Refrigeration: Used in supermarket cold chains and industrial freezers. TP2 tubes are often “inner-grooved” (adding internal micro-fins) to further increase the heat transfer surface area, making the system more energy-efficient.

- Evaporators and Condensers: The tube’s high thermal conductivity ensures that heat is exchanged rapidly between the refrigerant and the air.

6.2 Plumbing and Water Distribution

In many high-end residential and commercial buildings, TP2 copper is the preferred choice for water systems due to its longevity and health benefits.

- Potable Water: Copper is naturally antimicrobial, inhibiting the growth of bacteria like Legionella.

- Drainage and Venting: Because TP2 resists corrosion from greywater and harsh soaps, it is used for durable drainage systems that can last over 50 years.

- Gas Piping: Its ability to handle high pressure and resist fire (non-combustible) makes it the safest choice for transporting medical gases in hospitals or natural gas in homes.

6.3 Industrial and Chemical Applications

Beyond standard buildings, TP2 copper handles the “heavy lifting” in manufacturing plants.

- Heat Exchangers: Used in oil coolers, power plant steam condensers, and chemical processing.

- Process Piping: TP2 is ideal for transporting fluids that are non-acidic but require a stable temperature environment.

- Solar Thermal Collectors: Used in the “riser” tubes of solar water heaters to absorb and transfer solar heat to the water storage tank.

6.4 Electrical and Grounding Applications

While TP2 has slightly lower conductivity than pure T2 copper, its superior strength and corrosion resistance make it useful for specific electrical roles:

- Grounding Rods and Sleeves: Used to protect electrical systems from lightning and surges, especially in soil environments where corrosion is a risk.

- Terminals and Connectors: Used in heavy-duty electrical components where the part must be brazed or welded to another component.

Part 7: Joining Techniques for TP2 Copper Tubes

The reliability of a copper system depends heavily on the quality of its joints. Because TP2 is deoxidized, it offers the widest range of joining options without the risk of material degradation.

7.1 Soldering and Brazing

This is the most common method for TP2 tubes in HVAC and plumbing.

- Soldering (Soft Solder): Used primarily in residential plumbing. It involves filler metals with a melting point below 450°C.

- Brazing (Hard Solder): The “standard” for HVAC/R. It uses filler metals (often silver-based) with melting points above 450°C . TP2 copper’s resistance to hydrogen embrittlement allows for high-temperature brazing with a torch, creating a joint that is often stronger than the tube itself.

7.2 Mechanical Fittings

For environments where an open flame is not permitted (like “no-torch” zones in hospitals or high-tech factories), mechanical options are used:

- Press-fit: A tool crimps a fitting onto the tube, utilizing an internal O-ring for a seal.

- Compression Fittings: Uses a brass nut and ferrule to compress the TP2 tube against the fitting. This is common in low-pressure gas lines and instrumentation.

Part 8: Advantages and Disadvantages of TP2

To make an informed decision, it is helpful to see the “pros and cons” summarized.

Advantages

- Safe Welding: The high phosphorus content prevents cracks during high-temperature joining.

- Energy Efficiency: Exceptional thermal conductivity saves energy in heating/cooling applications.

- Durability: High resistance to general corrosion and internal scaling.

- Antibacterial: Naturally kills 99.9% of bacteria within two hours of contact.

- Sustainable: Fully recyclable and high scrap value.

Disadvantages

- Conductivity Trade-off: Its electrical conductivity is lower than T2 (pure copper).

- Cost Volatility: Like all copper products, the price is subject to global commodity market fluctuations.

- Theft Risk: Due to its high recycling value, exposed copper piping can be a target for theft on job sites.

Part 9: Maintenance and Care for Longevity

While TP2 copper is a “set it and forget it” material, following these tips ensures it lasts for decades:

- Avoid Excessive Flux: When soldering, use the minimum amount of flux required. Excess flux left inside the tube can cause localized pitting corrosion.

- Proper Support: Ensure tubes are supported by copper-plated or plastic-coated hangers. Avoid direct contact with galvanized steel or iron to prevent galvanic corrosion.

- Flow Velocity: In plumbing, keep water velocity within recommended limits (usually < 1.5 m/s for hot water) to prevent erosion-corrosion.

- Cleaning: For industrial heat exchangers, regular flushing with mild descaling agents will maintain the high thermal transfer rate of the TP2 walls.

Conclusion: The Future of TP2 Copper Tubes

TP2 copper tubes represent the perfect balance of metallurgy and practicality. By adding phosphorus to deoxidize the copper, engineers have created a material that is not only highly efficient at transferring heat but also incredibly reliable to install and join.

Whether it is in the air conditioning units that keep our homes comfortable, the plumbing that delivers safe water, or the cooling systems in the next generation of electric vehicles, TP2 remains the foundational material for modern thermal and fluid management. When choosing a material for high-pressure, high-temperature, or high-efficiency applications, TP2 (C12200) stands as the proven industry benchmark.

Part 10: Frequently Asked Questions (FAQ)

To conclude the article, here are some of the most common questions regarding TP2 copper tubes:

Q1: Can TP2 copper tubes be used for drinking water?

A: Yes. TP2 (C12200) is widely used in plumbing systems globally. It is naturally antimicrobial and meets the safety standards for potable water in most jurisdictions.

Q2: What is the main difference between TP1 and TP2?

A: The primary difference is the Phosphorus content. TP2 has a higher phosphorus range (0.013% to 0.050%), making it superior for heavy-duty welding and brazing, while TP1 (0.005% to 0.012%) offers slightly better thermal/electrical conductivity.

Q3: Why is TP2 preferred over T2 for HVAC applications?

A: T2 copper contains trace oxygen which causes “hydrogen embrittlement” during welding, leading to cracks. TP2 is deoxidized, meaning it can be brazed and welded repeatedly without losing structural integrity.

Q4: Are TP2 tubes compatible with new green refrigerants like R-32?

A: Yes. TP2 seamless tubes are designed to handle the higher operating pressures associated with modern eco-friendly refrigerants, provided the wall thickness is specified correctly.

Part 11: Final Comparison Summary (Selection Guide)

This table serves as a quick reference for engineers to choose the right grade of copper for their specific project.

| Material | Key Feature | Best For… | Welding/Brazing |

|---|---|---|---|

| T2 (Pure Copper) | Max Conductivity | Electrical Busbars, Grounding | Poor (Risk of cracking) |

| TP1 (Low-P) | High Thermal + Ductility | Precision Radiators, Heat Fins | Good |

| TP2 (High-P) | Maximum Reliability | HVAC, Plumbing, Gas Lines | Excellent (Industry Standard) |

Product Category

Content

- Part 1: Introduction to TP2 Copper Tubes

- Part 2: Standards and Specifications

- Part 3: Chemical Composition and Physical Properties

- Part 4: Manufacturing Process of TP2 Copper Tubes

- Part 5: Key Features and Benefits of TP2 Copper Tubes

- Part 6: Applications of TP2 Copper Tubes Across Industries

- Part 7: Joining Techniques for TP2 Copper Tubes

- Part 8: Advantages and Disadvantages of TP2

- Part 9: Maintenance and Care for Longevity

- Conclusion: The Future of TP2 Copper Tubes

- Part 10: Frequently Asked Questions (FAQ)

- Part 11: Final Comparison Summary (Selection Guide)

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español