Construction Industry Embraces Silver Copper Tubes for Long-Term Corrosion Resistance

The global construction industry is continuously evolving as developers, engineers, and contractors seek materials that offer durability, efficiency, and long-term value. In recent years, silver copper tubes have gained increasing attention as a reliable solution for projects where corrosion resistance, thermal performance, and longevity are critical. From commercial buildings and residential developments to infrastructure and industrial facilities, silver copper tubes are emerging as a preferred choice for modern construction applications.

This growing adoption reflects a broader industry shift toward materials that reduce maintenance costs, extend service life, and perform reliably in challenging environments. Many developers now work closely with a qualified copper tube factory to ensure material consistency, traceability, and long-term performance. As construction standards become more demanding and sustainability goals more prominent, silver copper tubes are finding their place as a strategic material rather than a niche option.

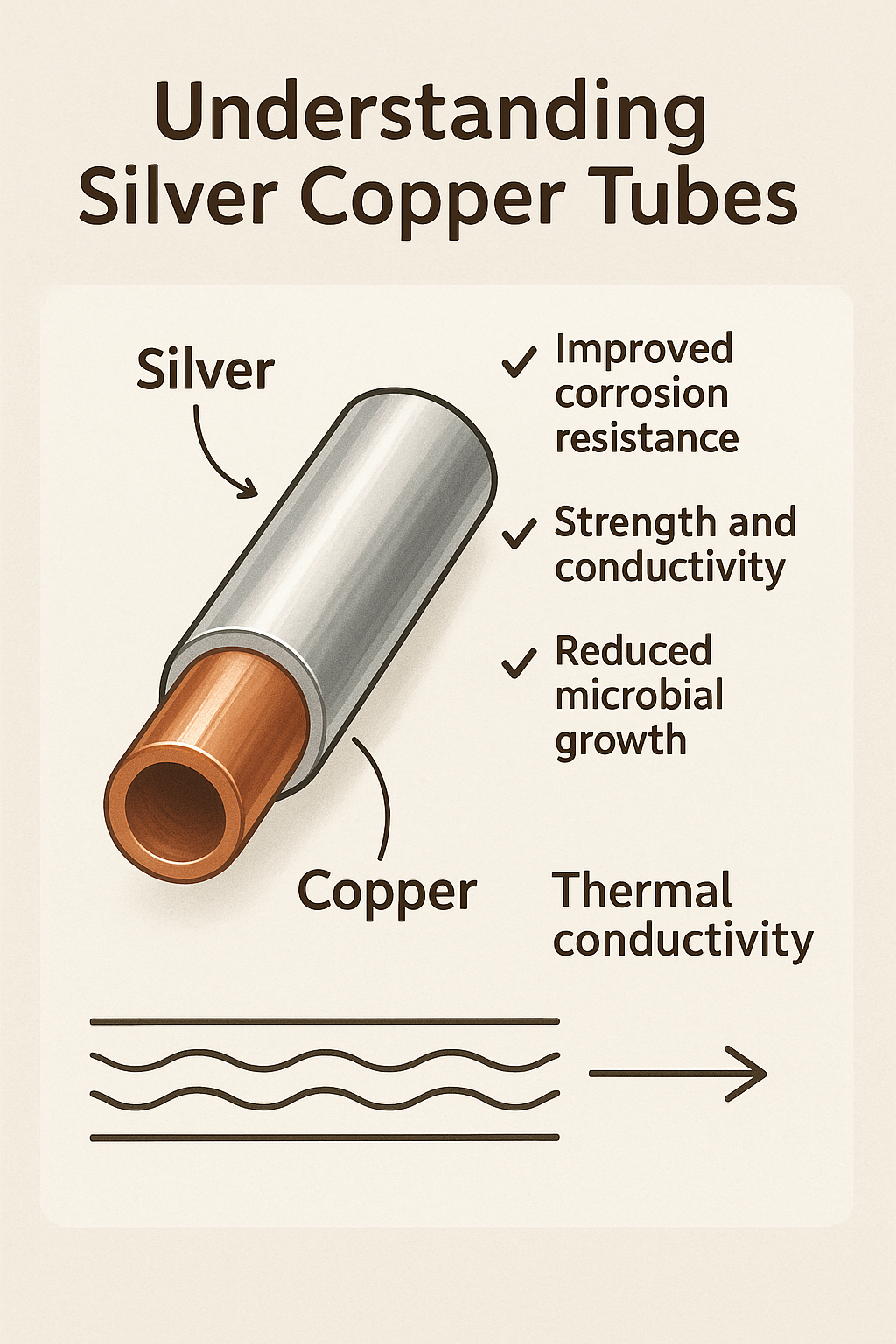

Understanding Silver Copper Tubes

Silver copper tubes are typically copper tubes enhanced with a small percentage of silver, either through alloying or surface treatment. This addition improves several inherent properties of copper without compromising its well-known advantages. Copper has long been valued in construction for its excellent thermal conductivity, formability, and resistance to many forms of corrosion. The inclusion of silver further enhances these characteristics, particularly in environments where moisture, chemicals, or temperature fluctuations can accelerate material degradation.

The result is a tube that maintains copper’s strength and conductivity while offering improved resistance to oxidation, stress corrosion cracking, and microbial growth. These benefits are especially relevant in modern construction, where systems are expected to operate efficiently for decades with minimal intervention.

Corrosion Resistance as a Key Driver

Corrosion remains one of the most costly challenges in construction. Piping failures due to corrosion can lead to water leaks, system downtime, structural damage, and expensive repairs. In applications such as plumbing, HVAC systems, fire protection, and industrial piping, material selection plays a crucial role in preventing these issues.

Silver copper tubes offer enhanced corrosion resistance compared to standard copper tubes, particularly in aggressive environments. Buildings located in coastal regions, industrial zones, or areas with high humidity often face accelerated corrosion due to salt air, pollutants, or fluctuating temperatures. Silver copper tubes provide an added layer of protection, helping systems maintain integrity under such conditions.

This improved resistance translates directly into longer service life. Developers and building owners increasingly recognize that investing in high-quality materials upfront can significantly reduce long-term operational costs. As a result, silver copper tubes are becoming a practical solution rather than a premium alternative.

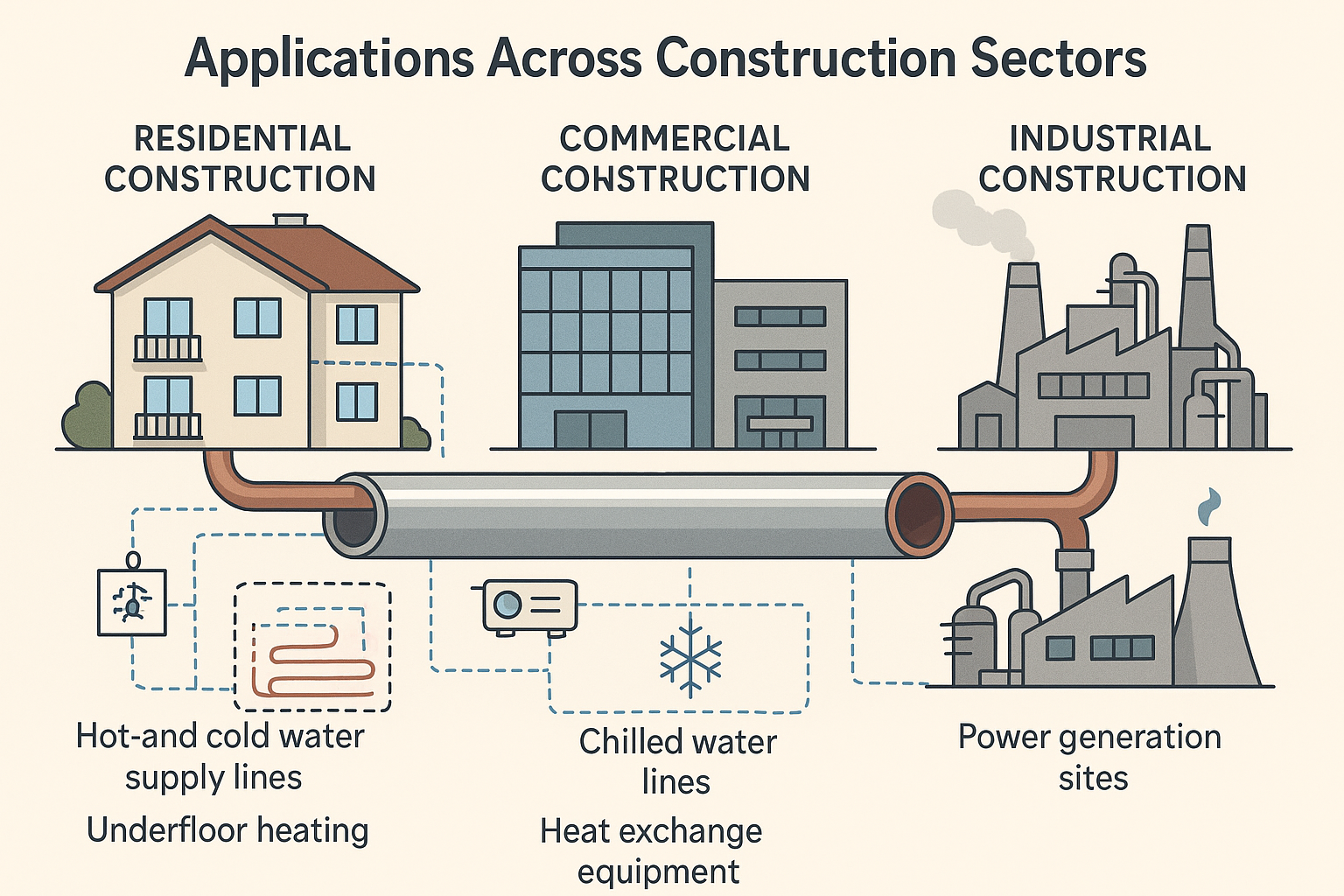

Applications Across Construction Sectors

The versatility of silver copper tubes makes them suitable for a wide range of construction applications. In residential construction, they are commonly used in hot and cold water supply lines, heating systems, and underfloor heating networks. Their durability helps reduce the risk of leaks and corrosion-related failures, which is especially important in multi-unit residential buildings.

In commercial construction, silver copper tubes are widely applied in HVAC systems, chilled water lines, and heat exchange equipment. Their excellent thermal conductivity ensures efficient heat transfer, while their corrosion resistance supports consistent performance over time. This is particularly valuable in large office buildings, hospitals, hotels, and shopping centers, where system reliability is essential.

Industrial construction also benefits from the use of silver copper tubes. Manufacturing plants, processing facilities, and power generation sites often involve exposure to chemicals, high temperatures, or pressure variations. Silver copper tubes can withstand these demanding conditions better than many conventional piping materials, making them a reliable choice for critical systems.

(This image was generated by AI.)

Supporting Sustainable Building Practices

Sustainability has become a central focus in construction, influencing material selection, design strategies, and project planning. Silver copper tubes align well with sustainable building objectives in several ways. First, copper is highly recyclable, and silver-enhanced copper products retain this advantage. At the end of a building’s life cycle, these materials can be recovered and reused without significant loss of performance.

Second, the long service life of silver copper tubes reduces the need for frequent replacement. Fewer replacements mean less material consumption, lower waste generation, and reduced environmental impact over time. This life-cycle efficiency is increasingly valued in green building certifications and sustainability assessments.

Additionally, the thermal efficiency of silver copper tubes contributes to energy savings. In heating and cooling systems, efficient heat transfer helps reduce energy consumption, supporting lower operating costs and reduced carbon emissions. As energy efficiency regulations become more stringent, materials that enhance system performance are gaining importance.

Installation and Compatibility Advantages

From a contractor’s perspective, ease of installation and system compatibility are important considerations. Silver copper tubes are generally compatible with standard copper fittings, joining methods, and tools. They can be soldered, brazed, or mechanically joined using familiar techniques, minimizing the learning curve for installers.

This compatibility allows contractors to integrate silver copper tubes into existing designs without major changes to installation practices. For renovation and retrofit projects, this is particularly beneficial, as it enables system upgrades without extensive redesign.

Furthermore, the mechanical strength and flexibility of silver copper tubes support precise installation in tight or complex layouts. This flexibility is valuable in modern construction, where space optimization and architectural complexity are increasingly common.

Cost Considerations and Long-Term Value

While silver copper tubes may have a higher initial cost compared to standard copper tubes, industry professionals are increasingly evaluating materials based on total life-cycle cost rather than upfront expense alone. When maintenance, repair, downtime, and replacement costs are taken into account, silver copper tubes often present a strong value proposition.

Corrosion-related failures can be costly, especially in large buildings where access to piping systems is limited. Preventing these issues through improved material selection can significantly reduce long-term expenditures. Building owners and facility managers are recognizing that investing in corrosion-resistant materials supports predictable budgeting and asset protection.

Industry Standards and Quality Assurance

The increased use of silver copper tubes in construction has driven greater attention to industry standards, certifications, and quality control. Manufacturers are responding by aligning products with international and regional standards for composition, performance, and safety. A reputable copper tube factory typically maintains strict quality management systems to meet these requirements. This ensures consistent quality and builds confidence among engineers, architects, and contractors.

Reliable sourcing and compliance with recognized standards allow project stakeholders to specify silver copper tubes with greater confidence, particularly in projects where safety and long-term reliability are critical.

Market Trends and Future Outlook

The growing interest in silver copper tubes reflects broader market trends shaping the construction industry. Urbanization, infrastructure renewal, and increased investment in energy-efficient buildings are driving demand for durable, high-performance materials. At the same time, climate-related challenges are placing greater stress on building systems, highlighting the need for corrosion-resistant solutions.

Looking ahead, continued research and development are likely to further enhance silver copper tube technology. Leading copper tube factory operators are investing in improved alloy design and production processes to support future construction demands. Improvements in alloy composition, manufacturing processes, and surface treatments may lead to even better performance and broader application potential.

Product Category

Content

- Understanding Silver Copper Tubes

- Corrosion Resistance as a Key Driver

- Applications Across Construction Sectors

- Supporting Sustainable Building Practices

- Installation and Compatibility Advantages

- Cost Considerations and Long-Term Value

- Industry Standards and Quality Assurance

- Market Trends and Future Outlook

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文