Why Fin Copper Tubes Are Essential for High-performance Heat Exchangers

In today's rapidly evolving industrial landscape, heat exchangers are at the heart of efficient thermal management systems across various sectors, including HVAC (heating, ventilation, and air conditioning), refrigeration, power generation, and automotive industries. Among the materials used in their design, fin copper tubes have emerged as a crucial component for ensuring high performance, reliability, and energy efficiency. As demand for more efficient systems grows globally, it’s important to understand why fin copper tubes are essential for optimizing heat transfer and enhancing the overall performance of heat exchangers.

Unmatched Thermal Conductivity

The primary reason why fin copper tubes are indispensable in high-performance heat exchangers lies in copper’s unparalleled thermal conductivity. Copper tubes, which have been a preferred material in thermal applications for decades, offer excellent heat transfer capabilities. Copper’s ability to efficiently move heat from one medium to another makes it an ideal choice in systems where heat exchange is the core function.

Compared to other materials, copper’s thermal conductivity is nearly three times higher than that of aluminum, significantly boosting the performance of heat exchangers. This is particularly valuable in high-temperature environments, such as industrial cooling systems or power plants, where precise temperature regulation is critical.

Comparison of Heat Transfer and Durability Performance

To illustrate why fin copper tubes are superior, we’ve created a comparison table showing the key performance metrics of commonly used materials in heat exchanger applications:

|

Material |

Thermal Conductivity (W/m·K) |

Corrosion Resistance |

Durability |

Applications |

|

Copper |

398 |

Excellent (resistant to moisture and chemicals) |

High (forms protective oxide layer) |

HVAC, refrigeration, automotive, power generation |

|

Aluminum |

235 |

Moderate (susceptible to corrosion in humid conditions) |

Moderate (prone to surface degradation) |

HVAC, automotive, refrigeration |

|

Stainless Steel |

16 |

Excellent (high resistance to rust and corrosion) |

Very High (extremely durable) |

High-pressure steam, chemical processing |

|

Titanium |

22 |

Very High (resistant to corrosion in harsh environments) |

Very High (strong and long-lasting) |

Marine cooling systems, high-end applications |

|

Carbon Steel |

50 |

Poor (prone to rust in moist conditions) |

Low (can corrode over time) |

Industrial cooling, basic applications |

From the table, it’s clear that fin copper tubes not only excel in thermal conductivity but also offer superior corrosion resistance compared to materials like aluminum and carbon steel. Their high durability, coupled with excellent thermal performance, makes copper the material of choice for many high-performance heat exchangers.

Enhanced Heat Transfer with Fin Design

In many heat exchangers, fins are attached to the copper tubes to increase the surface area in contact with the fluid, thus enhancing heat transfer efficiency. Fin copper tubes combine the thermal benefits of copper with the added surface area provided by the fin design. The fins, typically made of copper or aluminum, are affixed to the tube’s surface to facilitate more efficient heat transfer by allowing greater contact with the surrounding fluid.

The increased surface area provided by the fins allows fin copper tubes to improve thermal management in applications that need to dissipate large amounts of heat, such as in air conditioning systems, automotive radiators, and large-scale refrigeration units. In such applications, heat exchanger efficiency directly impacts system performance, energy consumption, and operating costs, which is why fin copper tubes are a preferred choice for engineers and manufacturers.

Corrosion Resistance and Durability

Another reason for the widespread use of copper tubes in heat exchangers is copper’s natural resistance to corrosion. This is especially important when tubes are exposed to harsh environmental conditions, such as moisture, chemicals, and extreme temperatures. Copper forms a protective oxide layer that shields it from further corrosion, making copper tubes and fin copper tubes more durable than many alternatives.

This characteristic ensures that copper tube manufacturers can offer long-lasting products that require less maintenance over time, reducing costs for industries relying on heat exchangers for their operations. Additionally, copper's resistance to corrosion makes fin copper tubes ideal for use in marine, coastal, and industrial cooling systems where other materials might degrade more quickly.

Energy Efficiency and Cost-effectiveness

With rising energy costs and increasing regulatory pressure to reduce carbon footprints, energy efficiency has become a critical focus across industries. The superior heat transfer capabilities of copper tubes help fin copper tubes reduce energy consumption. Efficient heat exchangers that use copper tubes require less energy to achieve the same level of performance, translating into lower operating costs for businesses and industries.

Although copper tubes may have a higher upfront material cost compared to alternatives such as aluminum, the long-term benefits—such as improved system efficiency, lower energy consumption, and reduced maintenance—make them a cost-effective choice. Over time, these factors contribute to substantial savings, particularly in large-scale industrial applications.

Applications Across Various Industries

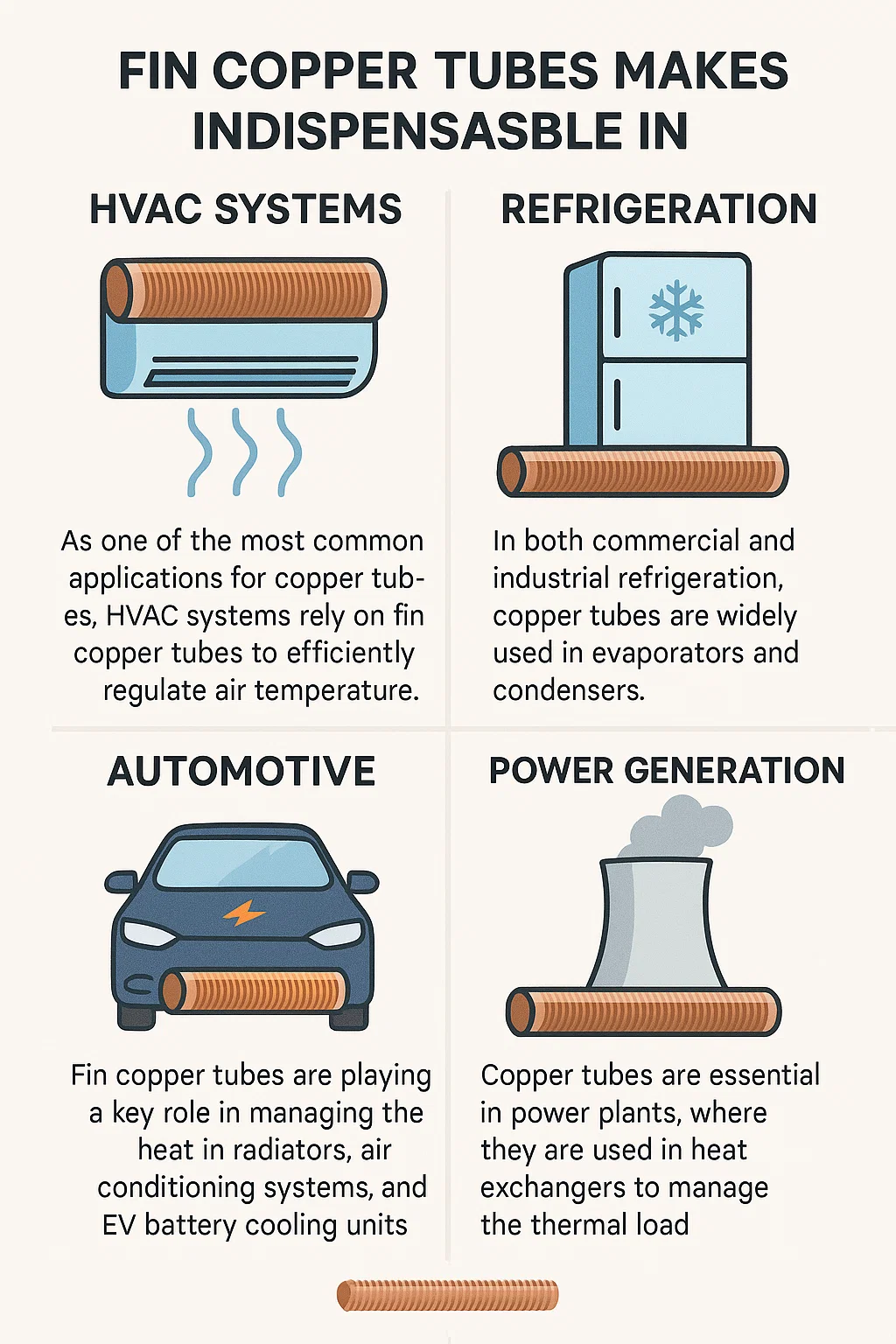

The versatility of fin copper tubes makes them indispensable in numerous industries, such as:

HVAC Systems: As one of the most common applications for copper tubes, HVAC systems rely on fin copper tubes to efficiently regulate air temperature. Copper's thermal conductivity ensures fast and reliable heat transfer in heating and cooling units.

Refrigeration: In both commercial and industrial refrigeration, copper tubes are widely used in evaporators and condensers. Their superior heat transfer properties allow these systems to operate efficiently, lowering energy consumption and reducing the environmental impact of refrigeration processes.

Automotive: As vehicles, especially electric vehicles (EVs), require increasingly sophisticated cooling systems, fin copper tubes are playing a key role in managing the heat in radiators, air conditioning systems, and EV battery cooling units. The enhanced thermal performance of copper helps prevent overheating, which is vital for the longevity and safety of these systems.

Power Generation: Copper’s high thermal conductivity also makes copper tubes essential in power plants, where they are used in heat exchangers to manage the thermal load in steam turbines and cooling towers. The durability and efficiency of fin copper tubes ensure that these systems run at optimal performance for extended periods.

The Role of Copper Tube Manufacturers in Innovation

The demand for high-performance heat exchangers has prompted copper tube manufacturers to continue innovating, improving the design and production processes of fin copper tubes. Advanced manufacturing techniques are now allowing for the production of copper tubes with optimized fin geometries that increase surface area while reducing material costs.

Moreover, there has been growing interest in improving the sustainability of fin copper tubes. Manufacturers are exploring ways to make copper tube production more eco-friendly, such as using recycled copper and developing energy-efficient manufacturing processes. These efforts not only enhance the environmental footprint of fin copper tubes but also align with the global shift towards greener industrial practices.

Product Category

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文