Is There a Great Divide Between Scale and Agility in the Global Copper Tube Industry?

Subtitle: As downstream demand fragments, copper tube manufacturers face a strategic crossroads: embrace high-volume standardization or pivot to high-value customization. The choice will redefine their competitive landscape.

Introduction

The copper tube, a foundational component in construction, HVAC, and industrial systems, is often perceived as a simple commodity. However, beneath this veneer of uniformity lies a deepening schism. The industry is splitting into two distinct paradigms: one driven by economies of scale and the other by agile, value-driven customization. This divergence is not merely about product specifications but reflects fundamental differences in production philosophy, market positioning, and future viability.

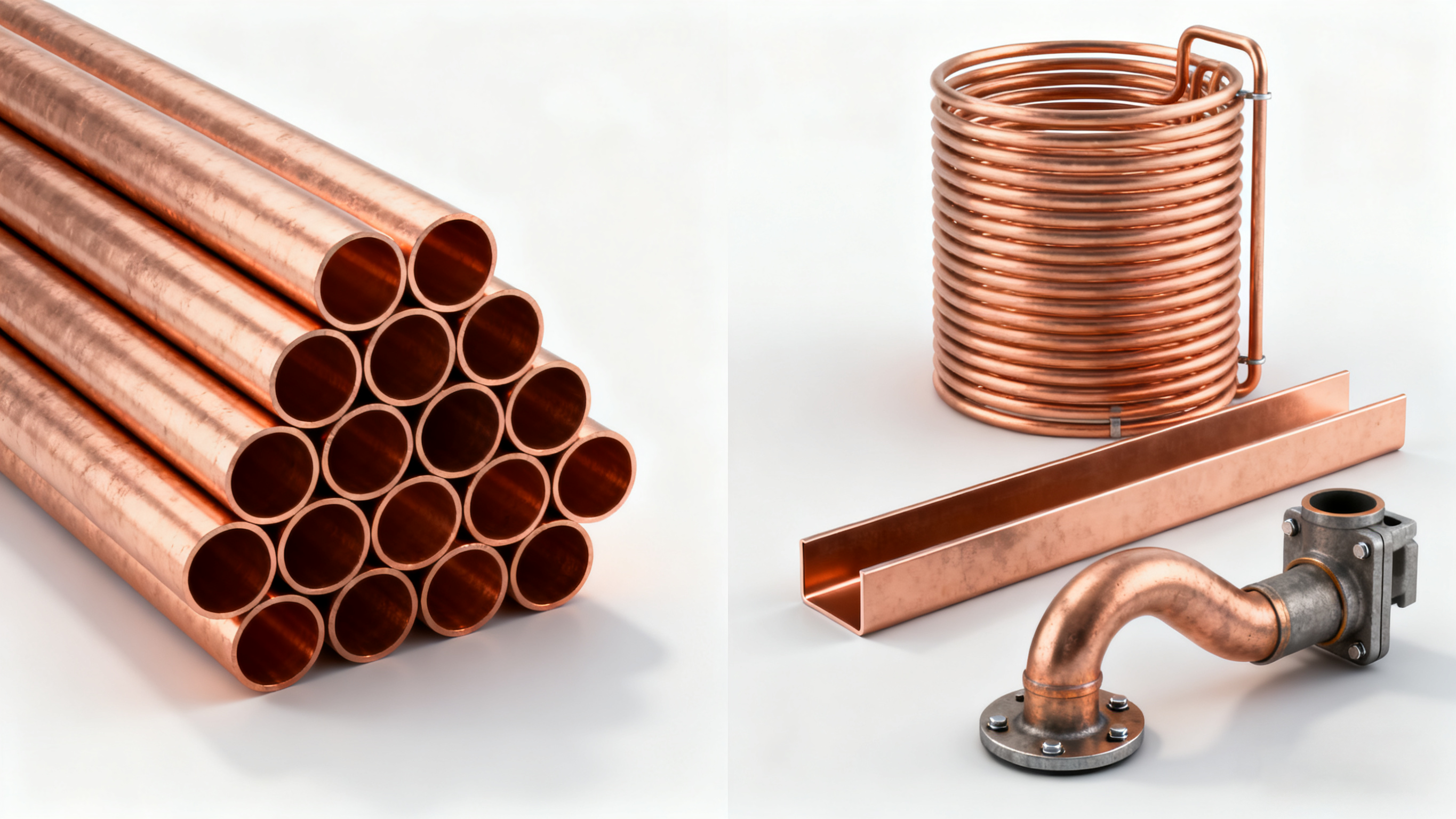

Caption: The strategic crossroads: Copper tube manufacturers must choose between the well-paved highway of volume production and the dynamic, winding path of specialized value creation.

The Reign of Scale: Standardized Copper Tube Production

Standardized copper tubes dominate global supply chains, serving high-volume applications where cost and consistency are paramount. These products—typically round, straight tubes of common alloys like T2 or TP2—are the lifeblood of residential plumbing and conventional HVAC systems.

Production Logic and Efficiency

- Highly Automated Lines: Integrated mills operate continuous casting, extrusion, and drawing lines optimized for minimal downtime.

- Cost Leadership: Competitive advantage hinges on raw material procurement, energy efficiency, and logistical optimization.

- Market Stability: Orders are often predictable, with pricing transparency and thin margins.

- Key Insight: A production manager at a leading mill notes, “Our goal is to deliver metric tons per hour, not meters per day. Variability is the enemy of efficiency.”

Limitations of Scale

- Limited Flexibility: Switching specifications requires costly line adjustments.

- Price Sensitivity: Vulnerable to commodity cycles and input cost fluctuations.

- Commoditization Pressure: Competition revolves primarily around price, not innovation.

The Rise of Agility: Customized Copper Tube Solutions

Driven by demand from sectors like electric vehicles, semiconductors, and specialized industrial equipment, customized tubes represent a high-growth niche. These products include:

- Shaped Tubes: Rectangular, multi-port, or coiled designs for compact heat exchangers.

- Advanced Alloys: CuNi, CuCrZr, or oxygen-free grades for corrosion resistance or high thermal conductivity.

- Precision Engineering: Tolerances within ±0.05mm and ultra-smooth surfaces for critical applications.

Caption: A tale of two tubes: The homogeneous world of standardized products (left) versus the diverse, application-specific universe of customized solutions (right).

Technological Enablers

- Flexible Manufacturing Cells: CNC bending, laser cutting, and non-destructive testing allow small-batch production.

- Digital Prototyping: Simulation tools optimize tube geometry for performance before physical production.

- Value-Based Pricing: Margins are shielded from commodity markets by technical differentiation.

Market Dynamics

- Collaborative Design: Manufacturers work directly with engineers to solve application-specific challenges.

- Lead Time vs. Cost: While production cycles are longer, customers prioritize reliability over speed.

Comparative Analysis: Scale vs. Agility

|

Dimension |

Standardized Tubes |

Customized Tubes |

|

Primary Driver |

Cost per meter |

Performance per application |

|

Production Focus |

Volume optimization |

Flexibility and precision |

|

Customer Relationship |

Transactional |

Collaborative partnership |

|

Innovation |

Incremental process improvements |

Material and design breakthroughs |

|

Risk Exposure |

Commodity price volatility |

Technological obsolescence |

Hybrid Strategies and Industry Evolution

Some manufacturers are blending both models by:

- Modular Platforms: Using standardized base tubes with customizable end-fittings.

- Regional Flexibility: Operating large-scale mills for volume and regional hubs for customization.

- Digital Integration: IoT-enabled production tracking for both batch and bespoke orders.

Challenges and Future Outlook

Scalability of Customization

- Skill Gaps: Demand for metallurgists and data analysts outstrips supply.

- Supply Chain Complexity: Sourcing small quantities of specialty alloys increases costs.

Sustainability Pressures

- Recyclability: Standardized tubes benefit from established recycling streams; customized alloys require new circular economy models.

- Carbon Footprint: Localized customization may reduce logistics emissions but increase energy use per unit.

Conclusion

The copper tube industry’s divergence into scale-driven and agility-driven models reflects broader trends in manufacturing. While standardized production will continue to anchor mass markets, the future of growth and innovation lies in customization. Success will require manufacturers to clearly choose their strategic path—or master the delicate balance of both.

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文