How Copper Tubes are Revolutionizing HVAC Systems in Commercial Buildings: Insights from Copper Tube Manufacturers and Suppliers

As the demand for energy-efficient and sustainable building solutions grows, one material remains at the forefront of HVAC (Heating, Ventilation, and Air Conditioning) innovation—copper tubes. These tubes are not only essential for the efficient functioning of HVAC systems in commercial buildings but are also pivotal in shaping the future of green building technologies. Copper tube manufacturers and suppliers play a crucial role in ensuring that businesses, construction companies, and HVAC specialists have access to high-quality, reliable copper products.

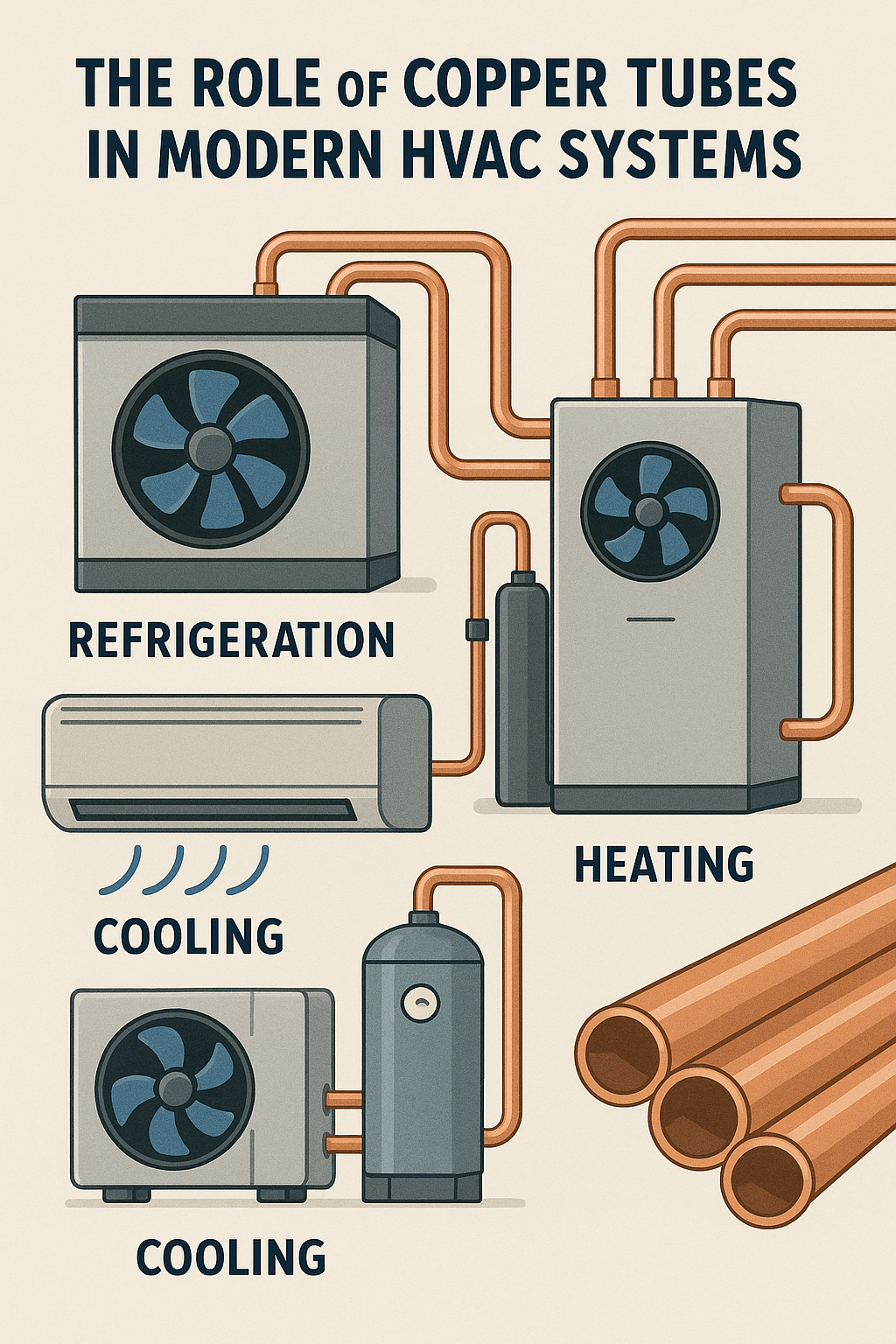

The Role of Copper Tubes in Modern HVAC Systems

Copper tubes have long been recognized as a critical component in HVAC systems, especially in the realms of refrigeration, cooling, and heating. Their role in the efficient transfer of heat, flexibility, and resistance to corrosion makes them an optimal choice for a wide range of HVAC applications. Whether in air conditioning units, heat pumps, refrigeration systems, or district heating networks, copper tubes provide unparalleled performance.

Superior Thermal Conductivity: Copper is known for its excellent thermal conductivity, meaning it can transfer heat much more efficiently than most other materials. HVAC systems that utilize copper tubes in their construction benefit from quicker heat exchange, ensuring faster cooling or heating in commercial environments. Whether cooling office spaces or maintaining optimal temperatures in industrial buildings, copper tubes ensure HVAC systems work with minimal energy expenditure.

Durability and Corrosion Resistance: One of copper's standout properties is its resistance to corrosion, which is particularly important for HVAC systems exposed to high moisture or changing temperatures. Copper tubes can withstand the harshest environmental conditions, from extreme heat to humidity, making them ideal for both indoor and outdoor HVAC installations. Over time, this durability reduces the likelihood of system failures and costly repairs, which is why copper tubes are favored for long-term commercial HVAC use.

Energy Efficiency and Cost Savings: HVAC systems account for a significant portion of energy consumption in commercial buildings. By incorporating copper tubes into these systems, businesses can significantly reduce energy use and operating costs. Copper tubes enable more efficient heat transfer, which leads to systems that consume less energy to achieve the desired temperatures. For building owners and facility managers focused on reducing operating costs and achieving sustainability goals, investing in copper tubes is a wise choice.

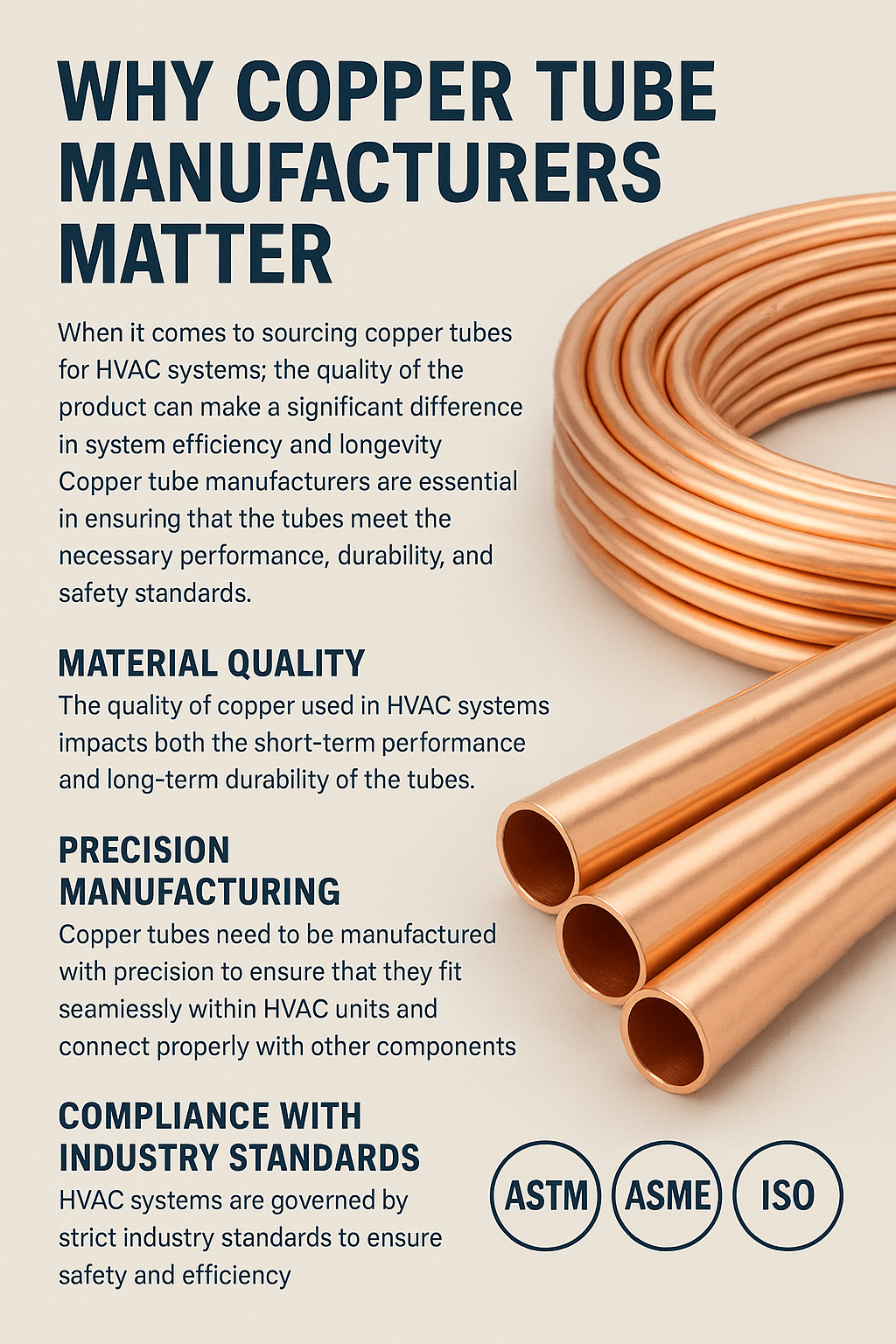

Why Copper Tube Manufacturers Matter

When it comes to sourcing copper tubes for HVAC systems, the quality of the product can make a significant difference in system efficiency and longevity. Copper tube manufacturers are essential in ensuring that the tubes meet the necessary performance, durability, and safety standards.

Material Quality: The quality of copper used in HVAC systems impacts both the short-term performance and long-term durability of the tubes. Trusted copper tube manufacturers ensure that only high-quality copper—often certified for use in HVAC and refrigeration systems—is used in the production of their products. This guarantees that the tubes will perform efficiently and withstand the rigorous demands of HVAC systems.

Precision Manufacturing: Copper tubes need to be manufactured with precision to ensure that they fit seamlessly within HVAC units and connect properly with other components. Leading manufacturers provide tubes with the correct diameter, thickness, and length to ensure compatibility with various systems. Moreover, specialized production techniques allow for the creation of bent or coiled copper tubes, ideal for more complex HVAC setups that require unique configurations.

Compliance with Industry Standards: HVAC systems are governed by strict industry standards to ensure safety and efficiency. Reputable copper tube manufacturers ensure that their products are compliant with international standards such as ASTM (American Society for Testing and Materials), ASME (American Society of Mechanical Engineers), and ISO (International Organization for Standardization). This compliance guarantees that copper tubes meet high-quality standards and are safe to use in HVAC systems.

The Role of Copper Tube Suppliers

Once copper tube manufacturers produce high-quality products, copper tube suppliers play a vital role in delivering these materials to businesses, contractors, and HVAC system designers. Copper tube suppliers help to ensure that HVAC professionals and building owners have timely access to the materials they need for installation, maintenance, and system upgrades.

Supply Chain Efficiency: Copper tube suppliers are essential in managing the flow of materials from manufacturers to end-users. A reliable supplier ensures that HVAC contractors can access copper tubes quickly, minimizing delays in system installation or repair. For commercial buildings with large HVAC demands, this ability to procure copper tubes in various sizes and quantities is key to keeping projects on track.

Customization and Flexibility: Many HVAC installations require custom-sized copper tubes, especially in large commercial projects. Suppliers that offer a wide range of tubing sizes and customization options enable HVAC designers to source exactly what they need. Whether the job requires longer tubes, specific wall thicknesses, or pre-bent copper tubes, experienced suppliers can meet these specialized needs.

Logistical Support: Copper tube suppliers often provide more than just the materials—they also offer logistical services to ensure smooth deliveries. With businesses increasingly demanding just-in-time deliveries to reduce inventory costs, suppliers who can meet tight deadlines and manage complex orders are highly valued in the HVAC industry. Additionally, suppliers may offer technical advice on the best copper tube options for different applications, helping customers make informed decisions.

Cost and Volume Discounts: Copper tubes, especially for large-scale commercial projects, can be a significant investment. Suppliers often work with businesses to offer bulk purchase discounts, which can make sourcing copper tubes more cost-effective. Furthermore, some suppliers may provide flexible pricing based on long-term relationships or regular orders, enabling businesses to reduce overall costs.

Emerging Trends in Copper Tube Use for HVAC Systems

As the building and HVAC industries evolve, new trends are shaping how copper tubes are used in commercial HVAC systems. Copper tube manufacturers and suppliers are increasingly adapting to meet these demands.

Integration of Smart Technologies: As smart building technologies become more prevalent, copper tubes are increasingly being used in HVAC systems that feature advanced sensors, automated temperature control, and energy-saving algorithms. These systems can adjust heating and cooling needs based on occupancy, weather, and real-time energy consumption data, enhancing the efficiency of copper tube-based HVAC systems.

Sustainability and Green Building: Sustainability continues to be a key focus in modern construction. Copper’s recyclability, coupled with its energy-efficient properties, makes it a go-to material for green building projects. Commercial buildings striving for LEED (Leadership in Energy and Environmental Design) certification or other sustainability certifications often rely on copper tube HVAC systems as part of their eco-friendly infrastructure.

Global Demand for Copper: The growing global demand for copper is driving manufacturers and suppliers to expand their production capacity and ensure steady supply chains. The rise of emerging markets in Asia, Latin America, and Africa is contributing to a surge in copper usage for HVAC systems. This global demand also encourages the development of new copper alloys and treatments that improve performance in specialized applications.

Reduced Environmental Impact: Innovations in copper tube manufacturing processes are helping to reduce the environmental impact of copper production. For example, some manufacturers are adopting low-energy or eco-friendly techniques to reduce carbon emissions during production. This trend aligns with the broader push for sustainability in the HVAC sector, as more businesses seek to minimize the environmental footprint of their operations.

|

Feature/Material |

Copper Tubes |

Aluminum Tubes |

Steel Tubes |

|

Thermal Conductivity |

Excellent, one of the best in materials |

Lower, less efficient than copper |

Very low, not suitable for heat exchange |

|

Corrosion Resistance |

High, resists most corrosive factors |

Poor, prone to oxidation and corrosion |

Poor, prone to rusting |

|

Durability |

High, long lifespan |

Lower, tends to wear out faster |

Good, but sensitive to environmental factors |

|

Weight |

Heavier |

Lighter, easier to handle |

Heavy, increases transport and installation costs |

|

Maintenance Costs |

Low, due to resistance to corrosion and wear |

High, requires frequent maintenance |

High, rust leads to frequent replacements |

|

Energy Efficiency |

Very high, excellent heat exchange |

Lower, less efficient than copper |

Very low, inefficient compared to copper and aluminum |

|

Environmental Impact |

Fully recyclable, low carbon footprint |

Recyclable, but higher production energy |

Recycling is more energy-intensive and carbon-heavy |

|

Cost |

Higher upfront, but low operating costs |

Lower upfront, but higher maintenance |

Lower upfront, but higher operating and maintenance costs |

Choosing the Right Copper Tube Manufacturer and Supplier

For HVAC professionals and building owners, selecting the right copper tube manufacturer and supplier is crucial. When making a choice, it’s important to consider the following factors:

- Reputation and Experience: Look for manufacturers and suppliers with a solid reputation for producing high-quality copper products. Experienced players in the market often have the technical knowledge to recommend the right copper tubes for specific HVAC applications..

- Product Range: Ensure that the supplier offers a wide range of copper tubes in various sizes, thicknesses, and forms (e.g., straight, coiled, or bent tubes) to suit different types of HVAC installations.

- Customer Service: Reliable customer service is key, especially for businesses that need timely deliveries or technical support.

- Sustainability Practices: If sustainability is a priority, choose manufacturers and suppliers that adhere to eco-friendly production methods and offer recyclable copper products.

Product Category

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文