Why DHP Copper Tubes Are Gaining Popularity in the Refrigeration Industry

In recent years, DHP copper tubes have seen a surge in demand within the refrigeration industry. This growing trend is not coincidental. DHP, or Deoxidized High-Phosphorus copper, is a specialized form of copper that possesses distinct advantages over traditional copper in specific industrial applications. With refrigeration systems becoming increasingly advanced and energy-efficient, materials like DHP copper tubes are essential for achieving optimal performance and durability.

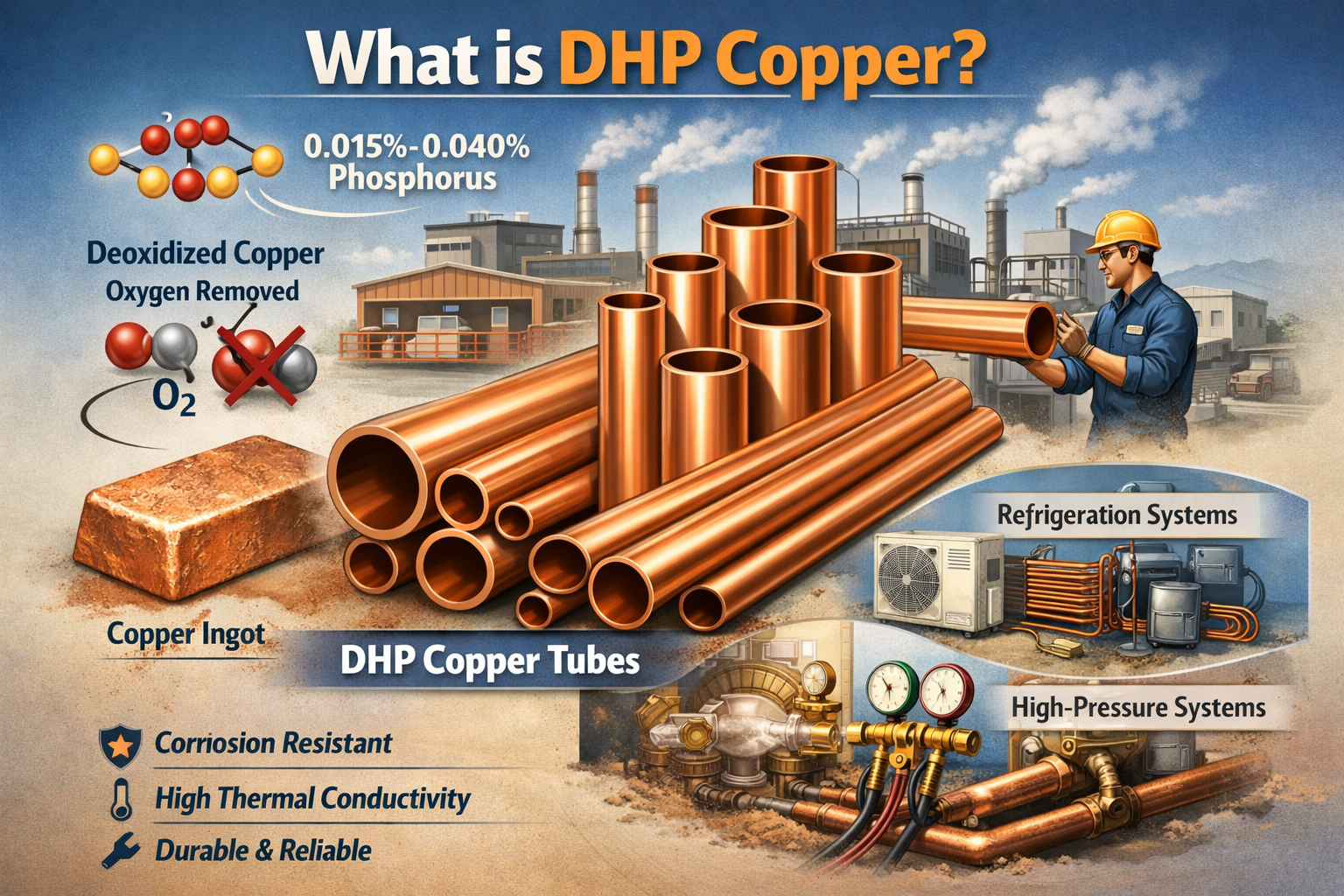

What is DHP Copper?

DHP copper is a high-quality, deoxidized copper alloy that contains a small amount of phosphorus, typically between 0.015% and 0.040%. The primary characteristic of this copper is that it has been treated to remove oxygen, a process that improves its resistance to corrosion and ensures better performance in high-pressure systems. The phosphorus content further enhances its properties, making it ideal for use in applications where durability, heat conductivity, and strength are critical.

Unlike other forms of copper, DHP copper is specifically designed for applications where high levels of cleanliness and the prevention of oxidation are important. This makes it a preferred choice for refrigeration systems, where the need for long-lasting, reliable performance is crucial. A copper tube factory that specializes in DHP copper tubes ensures that each tube is manufactured to the highest standards, using advanced techniques to guarantee uniform quality and performance.

(This image was generated by AI.)

The Importance of Copper in Refrigeration Systems

Copper has long been a material of choice in the manufacturing of refrigeration tubes. Its excellent thermal conductivity ensures efficient heat transfer, which is essential for the cooling process in refrigeration systems. Copper is also highly resistant to corrosion, particularly in low-oxygen environments, which is common in many refrigeration applications. This corrosion resistance is especially important because it helps maintain the integrity of the system and prevents leaks that could lead to costly repairs.

As refrigeration technology advances, so too does the need for more reliable and durable materials. While traditional copper tubes have been widely used for decades, DHP copper tubes offer several distinct advantages that make them a more effective choice for modern refrigeration systems.

Advantages of DHP Copper Tubes in Refrigeration

| Advantage | Description |

| Enhanced Corrosion Resistance | DHP copper is less prone to corrosion due to the deoxidation process and added phosphorus, improving system reliability and reducing the need for frequent repairs. |

| Improved Heat Transfer Efficiency | DHP copper’s high thermal conductivity ensures efficient cooling and heating, improving the overall performance of refrigeration systems. |

| Stronger and More Durable | DHP copper tubes offer better mechanical strength, making them ideal for high-pressure systems that require long-lasting durability. |

| Easier to Work With | DHP copper tubes are easier to bend, solder, and weld, allowing for quicker and more efficient installation in complex refrigeration systems. |

| Environmental Benefits | DHP copper is highly recyclable, reducing waste and supporting sustainability in refrigeration system design and operation. |

Enhanced Corrosion Resistance

One of the primary reasons DHP copper tubes are becoming increasingly popular in refrigeration applications is their superior resistance to corrosion. Traditional copper can suffer from oxidation over time, which can lead to the formation of copper oxide and other compounds that compromise the material's structural integrity. DHP copper, on the other hand, is less prone to corrosion due to the deoxidation process and the addition of phosphorus. This makes it an excellent choice for refrigeration systems, where exposure to moisture and various chemicals is common.

Additionally, the corrosion resistance of DHP copper ensures that the refrigeration system remains efficient over its lifetime, reducing the likelihood of expensive repairs and replacements. A reliable copper tube factory ensures that their DHP copper tubes meet industry standards, offering peace of mind to users.

Improved Heat Transfer Efficiency

Heat transfer efficiency is critical in refrigeration systems, where maintaining a precise temperature is key to energy savings and performance. DHP copper tubes excel in this area due to their superior thermal conductivity. The high heat transfer rate of DHP copper ensures that refrigeration systems can cool and heat up more quickly, which leads to better overall performance.

Moreover, the improved heat transfer efficiency also contributes to the reduction of energy consumption. As energy efficiency becomes an increasingly important factor in the design and operation of refrigeration systems, DHP copper tubes play a crucial role in helping businesses reduce their environmental impact while also lowering operating costs.

Stronger and More Durable

DHP copper tubes are stronger and more durable than standard copper tubes. This added strength is crucial in refrigeration systems, which often operate under high pressure and extreme conditions. DHP copper’s enhanced mechanical properties make it more resistant to deformation and rupture, ensuring that the system remains intact under demanding operational scenarios.

Furthermore, DHP copper’s durability means that refrigeration systems made with this material are more reliable over the long term. This translates into reduced downtime, fewer maintenance requirements, and a longer lifespan for the entire system. A copper tube factory that specializes in DHP copper tubes ensures that these tubes are manufactured with high-quality materials and precise specifications to meet the demanding needs of refrigeration systems.

Easier to Work With

Another advantage of DHP copper is that it is easy to work with, particularly when it comes to bending, soldering, and welding. The high phosphorous content of DHP copper allows for more flexibility during installation, which is especially beneficial in tight spaces or complex configurations that are common in refrigeration systems.

The ease of fabrication also reduces labor costs and increases installation speed, making DHP copper tubes an attractive option for businesses that need to install refrigeration systems quickly and efficiently. A well-equipped copper tube factory can ensure that the manufacturing process is streamlined to produce tubes with the best possible shape and strength.

Environmental Benefits

As sustainability becomes a higher priority across industries, the environmental benefits of using DHP copper cannot be overlooked. DHP copper tubes are highly recyclable, contributing to the circular economy by reducing the need for new raw materials. Additionally, the long-lasting nature of DHP copper ensures that refrigeration systems require fewer replacements, further decreasing the environmental impact over time.

The ability to recycle DHP copper tubes also means that copper tube factories play a key role in reducing waste and ensuring that the materials used in refrigeration systems have a minimal environmental footprint.

Applications of DHP Copper Tubes in Refrigeration

The versatility of DHP copper tubes makes them suitable for a wide range of refrigeration applications. Let’s take a look at some of the most common uses in the industry:

| Application | Description |

| Commercial Refrigeration Systems | DHP copper tubes are used in refrigeration units in supermarkets, cold storage facilities, and air conditioning systems to ensure reliable performance and long-term durability. |

| HVAC Systems | In HVAC systems, DHP copper tubes improve heat exchange efficiency, making them an essential component for both residential and commercial applications. |

| Automotive Air Conditioning | DHP copper tubes are used in automotive systems to maintain reliable performance in air conditioning units, offering superior corrosion resistance and durability. |

| Food & Beverage Industry | Used in food processing and storage, DHP copper tubes maintain temperature control, ensuring the freshness and safety of perishable goods. |

| Marine Refrigeration Systems | In marine refrigeration, DHP copper tubes are highly valued for their ability to resist saltwater corrosion, making them ideal for ships and offshore platforms. |

Commercial Refrigeration Systems

DHP copper tubes are widely used in commercial refrigeration systems, including supermarket refrigeration units, cold storage facilities, and large-scale air conditioning systems. The excellent corrosion resistance and heat transfer properties of DHP copper make it ideal for these high-demand applications, where long-term reliability and efficiency are paramount.

HVAC Systems

DHP copper tubes are also a popular choice in HVAC (heating, ventilation, and air conditioning) systems. These systems rely on efficient heat exchange, and DHP copper tubes help ensure that HVAC systems operate smoothly and with optimal energy efficiency. Whether in residential or commercial settings, HVAC systems benefit greatly from the durability and performance of DHP copper tubes.

Automotive Air Conditioning

DHP copper tubes are used in automotive air conditioning systems to maintain vehicle cabin comfort. Due to their corrosion resistance and ability to withstand high-pressure environments, these tubes are an excellent choice for automotive manufacturers looking to improve the reliability and longevity of their air conditioning systems.

Refrigeration in the Food and Beverage Industry

The food and beverage industry relies heavily on refrigeration for everything from storage to transportation. DHP copper tubes ensure that refrigeration systems remain operational in environments where temperature control is critical. Whether used in food processing plants, distribution centers, or retail locations, DHP copper tubes help maintain the quality and safety of perishable goods.

Marine Refrigeration Systems

In marine environments, refrigeration systems are exposed to saltwater and humid conditions that can quickly cause traditional materials to corrode. DHP copper tubes offer the ideal solution for these conditions, providing the durability and resistance needed for marine refrigeration applications.

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文