What Are the Multiple Applications of Copper Tube in Different Industrial Fields?

Copper tubes have long been a cornerstone in various industrial sectors due to their superior durability, excellent thermal conductivity, and corrosion resistance. As industries continue to innovate and pursue higher efficiency, the demand for copper tubes has surged.

HVAC and Refrigeration Systems

One of the most well-known applications of copper tubes is in heating, ventilation, air conditioning (HVAC) and refrigeration systems. Copper’s exceptional thermal conductivity allows for efficient heat transfer, making it the material of choice for air conditioning and refrigeration systems. Copper Tube Manufacturers worldwide produce high-quality tubes for use in condensers, evaporators, and refrigerant lines, ensuring optimal energy efficiency and maintaining low maintenance costs. The material's resistance to corrosion, especially in humid environments, further increases the reliability and longevity of these systems.

The global demand for copper tubes in HVAC and refrigeration continues to rise, with key markets in Southeast Asia, Europe, Africa, and the Middle East showing robust growth. Although the air conditioning industry’s growth rate has slightly slowed, the demand for copper tubes remains on an upward trajectory. Copper Tube Factories in Asia, which are the world’s largest producers, continue to meet the growing need for copper components in this sector. Despite slight market slowdowns in certain regions, ongoing infrastructure expansion in developing nations promises sustained demand.

|

Industry Sector |

Main Applications of Copper Tubes |

Market Trends and Demand |

|

HVAC and Refrigeration |

Used in air conditioning and refrigeration systems (condensers, evaporators, refrigerant lines). |

Asia is the largest producer of copper tubes. Despite a slowdown in the air conditioning industry, demand for copper tubes continues to grow, especially in Southeast Asia, Europe, Africa, and the Middle East. |

|

Plumbing Systems |

Used for potable water pipes, gas lines, and heating systems, offering corrosion resistance and antimicrobial properties. |

Copper remains the material of choice in developed countries (e.g., US, UK) for plumbing, with stable demand driven by high-end construction and sustainable building projects. |

|

Solar Thermal Systems |

Copper tubes are used in solar water heaters for efficient heat transfer. |

As renewable energy demand rises, the need for copper tubes in solar thermal systems grows, with manufacturers ramping up production to meet demand. |

|

Automotive Industry |

Used in automotive cooling systems, air conditioning, and brake lines. |

Copper tubes are essential for automotive systems, especially in air conditioning and power steering, offering durability and high-pressure resistance. |

|

Electronics and Electrical |

Used in heat dissipation systems for high-power components (e.g., heat sinks, cooling loops). |

With the increasing need for efficient cooling in electronic devices, demand for copper tubes in electronics continues to rise, particularly in high-performance computing and power equipment. |

|

Oil and Gas Industry |

Used for fluid and gas transmission, pressure sensors, and temperature sensors. Copper's corrosion resistance is key. |

Copper tubes are in steady demand for oil and gas operations, especially in offshore drilling platforms and harsh environments. |

|

Medical and Healthcare |

Used in medical devices such as infusion pumps, respiratory equipment, and surgical tools. Copper's antimicrobial properties are crucial. |

The healthcare industry is increasing its use of copper tubes, especially in precision instruments and medical cooling systems. |

|

Food and Beverage Industry |

Used in heat exchangers and cooling systems, essential for temperature control during processes like pasteurization and fermentation. |

Copper tubes continue to see growth in food processing and beverage production, especially in cooling systems used in brewing and distillation. |

|

Construction and Architecture |

Used in plumbing, heating systems, and decorative architectural elements. Copper's longevity, corrosion resistance, and aesthetic appeal make it popular. |

In developed markets, copper tubes remain the material of choice for high-quality plumbing and heating systems. In emerging markets, demand is increasing as urbanization and construction grow. |

|

Desalination and Marine Engineering |

Copper alloys (e.g., copper-nickel tubes) are used in seawater desalination and marine engineering projects due to excellent corrosion resistance and heat transfer properties. |

With the growing demand for desalination technologies, copper tubes are crucial for seawater desalination and marine equipment, despite higher production costs. |

Plumbing Systems

Copper tubes have been a staple in plumbing systems for decades. Known for their ability to resist corrosion and microbial growth, copper pipes are ideal for delivering clean water and gas. In residential, commercial, and industrial buildings, copper tubes are used for potable water systems, heating systems, and gas lines. Their ability to withstand extreme temperatures and pressures makes them a long-lasting and safe choice, especially in areas where water quality is a concern. Furthermore, copper pipes are highly recyclable, making them an eco-friendly option.

In developed countries like the U.S. and the UK, Copper Tube Manufacturers continue to supply high-quality copper pipes for plumbing applications, especially in the real estate and construction sectors. While there has been a slight decline in copper pipe consumption in recent years, driven by the increasing use of alternative materials, copper pipes remain essential in premium, high-quality construction projects. As the demand for sustainable and durable building materials grows, Copper Tube Factories are increasing their production capacity to meet the needs of developing countries, further boosting global market demand.

Solar Thermal Systems

With the rising demand for renewable energy, copper tubes are gaining prominence in solar thermal systems. Copper’s excellent heat conductivity makes it an ideal material for collecting solar energy and converting it into thermal energy for water heating. The use of copper tubes in solar collectors enhances efficiency and performance, helping to reduce reliance on conventional energy sources and contributing to greener, more sustainable living. The corrosion-resistant properties of copper ensure the longevity and reliability of solar thermal systems.

Copper Tube Manufacturers are expanding their production of copper tubes specifically designed for use in solar thermal applications, contributing to the growing renewable energy market. As more regions adopt sustainable energy solutions, the demand for copper tubes in these systems is expected to rise.

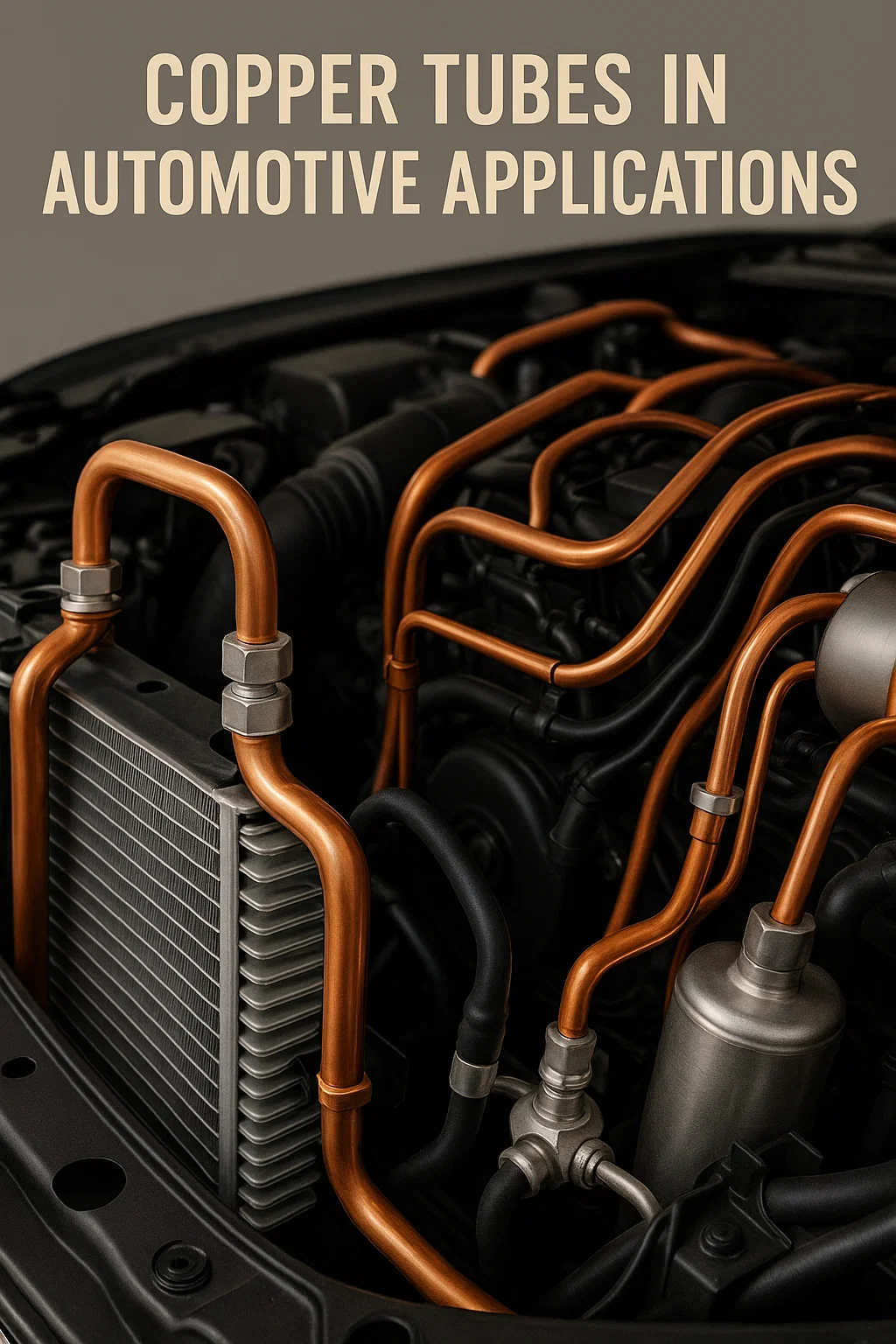

Automotive Industry

Copper tubes have found numerous applications in the automotive industry, particularly in cooling systems, heat exchangers, and brake lines. Copper Tube Manufacturers are at the forefront of producing precision tubes for automotive applications, ensuring the highest standards of durability and performance. In modern vehicles, copper tubes are used for engine cooling, air conditioning, and power steering systems, ensuring optimal performance even under high stress. The durability and flexibility of copper tubes make them a preferred choice in the automotive sector, as they can withstand the harsh conditions under the hood, including high temperatures and pressure variations.

Electronics and Electrical Equipment

In the electronics and electrical industries, copper tubes are used in heat dissipation systems, especially for high-power components that generate significant heat. Copper’s high thermal conductivity is leveraged to design cooling solutions such as heat sinks and cooling loops that ensure the optimal functioning of sensitive electronic devices. Additionally, copper’s high electrical conductivity makes it essential in the manufacturing of power cables and components within electrical equipment, where precise and efficient power transmission is necessary.

Copper Tube Factories play a pivotal role in the electronics sector by providing high-quality copper tubes used in thermal management systems and power transmission components. As electronic devices continue to get smaller and more powerful, the demand for efficient cooling solutions has led to a steady increase in the need for copper tubes.

Oil and Gas Industry

Copper tubes are commonly used in the oil and gas industry, particularly for fluid and gas transmission, as well as for safety and control systems. The corrosion resistance of copper ensures that pipelines and equipment remain intact in harsh environments, such as offshore drilling platforms and deep-sea operations. Copper Tube Manufacturers produce specialized tubes to meet the rigorous demands of the oil and gas sector, including in pressure gauges, temperature sensors, and control lines.

The material’s resistance to corrosion and scale build-up improves the overall efficiency and safety of operations in the oil and gas sector, making copper tubes a critical component in these industries.

Medical and Healthcare Equipment

The medical industry has long relied on copper tubes for a range of applications. Copper’s natural antimicrobial properties make it an excellent material for medical devices that require hygiene and safety, such as infusion pumps, respiratory equipment, and surgical tools. Copper Tube Manufacturers supply medical-grade copper tubes that are essential for applications in heat exchangers, medical cooling systems, and precision instruments. Copper’s ability to resist corrosion ensures the longevity and effectiveness of these medical devices.

Food and Beverage Industry

In the food and beverage industry, copper tubes are used in heat exchangers and cooling systems to maintain the correct temperature during production processes. Copper’s thermal efficiency helps speed up heat transfer, making it essential in pasteurization, fermentation, and refrigeration processes. The material is also used in the creation of equipment such as distillation columns, ensuring quality control and efficiency in processes like brewing and beverage production. Furthermore, copper’s non-reactive nature with food ensures that there is no contamination, maintaining the purity of the products.

Construction and Architecture

In the construction industry, copper tubes are used for both functional and aesthetic purposes. In architectural designs, copper is valued for its attractive appearance, especially when exposed to weathering, which gives it a distinct patina. Copper tubes are commonly used in roofing, drainage systems, and decorative features. Copper’s longevity, coupled with its resistance to weathering, corrosion, and fire, ensures that buildings equipped with copper elements maintain their structural integrity and aesthetic appeal over time.

In both the developed and developing world, Copper Tube Manufacturers continue to provide essential materials for the construction sector. Despite competition from alternative materials, copper remains a top choice in high-end residential, commercial, and sustainable building projects. The demand for copper in real estate development and construction is expected to rise, particularly in emerging markets.

Desalination and Marine Engineering

Copper alloys, particularly copper-nickel tubes, have gained significant traction in seawater desalination and marine engineering projects. The excellent electrical conductivity, heat transfer efficiency, and corrosion resistance of copper make it ideal for applications in desalination plants and offshore oil rigs, where exposure to saltwater can quickly degrade other materials. Copper tubes are used in the cooling systems of desalination plants and marine equipment, offering reliability and durability in harsh marine environments.

As the global demand for desalination technology rises, driven by the need to address water scarcity, the role of Copper Tube Manufacturers in supplying specialized copper tubes for these applications will become increasingly important. The long-term viability of these high-performance copper products will continue to make them essential in marine and desalination projects.

Product Category

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文