How Can Copper Tube Manufacturers Navigate the Challenges and Seize Opportunities Amid Soaring Copper Prices?

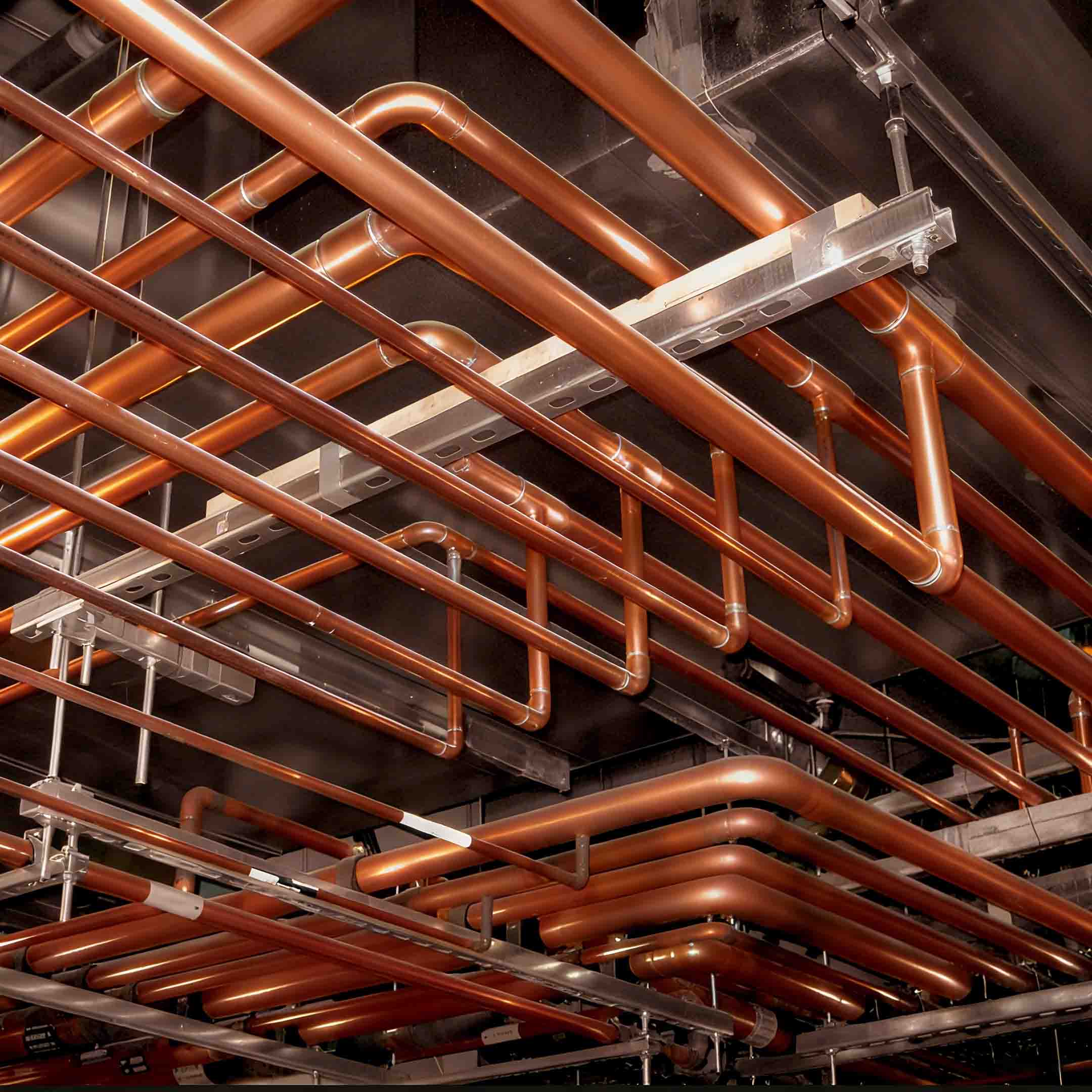

The recent surge in global copper prices, consistently reaching record highs, has caused significant disruptions across global manufacturing supply chains. As a core material in industries like HVAC systems, building plumbing, refrigeration equipment, and other industrial applications, copper is indispensable. This price spike is placing substantial pressure on the copper tube industry, especially copper tube manufacturer and copper tube factory that rely on copper as a primary raw material.

While the rising costs present challenges, they also bring opportunities for copper tube manufacturers to innovate. To navigate this crisis, copper tube factories are increasingly turning to technological advancements, product upgrades, and market diversification. By leveraging cutting-edge manufacturing technologies and exploring alternative materials, the industry is not only working to mitigate cost increases but also aiming to improve product performance and sustainability.

The global demand for copper tube remains strong, and this period of disruption could act as a catalyst for industry-wide transformation. For copper tube manufacturers, embracing innovation and diversification could lead to long-term growth and increased market share, positioning them for success in a rapidly changing market.

Challenges Facing Copper Tube Manufacturers: Cost Pressure and Market Contraction

The copper raw material cost typically represents over 70% of the total production cost for a copper tube manufacturer. Therefore, any fluctuations in copper prices directly affect the profitability and stability of copper tube factories. The current high-price environment is creating a series of challenges for copper tube manufacturers:

1. Sharply Reduced Profit Margins

As copper tube manufacturers face the dilemma of "expensive raw materials," they are struggling to maintain profit margins. While some of the increased costs can be passed downstream, the fierce competition in the copper tube industry restricts the ability to raise prices. This is especially difficult for small and medium-sized enterprises, where profit margins are squeezed to critical levels.

2. Cash Flow Strain

High raw material prices require copper tube manufacturers to allocate more working capital to maintain the same level of production and inventory. This puts significant pressure on corporate cash flow. Without efficient cash management, businesses may find themselves in a difficult financial position, affecting their ability to stay competitive in the market.

3. Increased Order Uncertainty

End customers, including air conditioner manufacturers and construction developers, may delay or cancel projects due to high material costs, creating a ripple effect for copper tube manufacturers. This uncertainty leads to a reduction in new orders and heightens the risks of price volatility for existing contracts, making it harder for copper tube factories to plan and maintain steady revenue streams.

Opportunities for Copper Tube Manufacturers: Driving Industrial Upgrading and Innovation

Despite the unprecedented challenges posed by rising copper prices, this cost crisis is also acting as a catalyst for industry consolidation and a shift towards high-quality development in the copper tube industry. Forward-thinking copper tube manufacturers are seizing new opportunities for technological innovation, market expansion, and enhanced product offerings in the following key areas:

1. Technological Innovation and Process Optimization

To cope with rising raw material costs, copper tube manufacturers are increasing their R&D investments to improve production processes. Techniques such as continuous casting and rolling are being optimized to enhance material utilization and yield rates. This enables manufacturers to "squeeze" profits from within by producing high-efficiency, thin-walled copper tubes. Such innovations have become a focal point for R&D, helping companies improve their cost structure while maintaining product quality.

2. Research and Application of Alternative Materials

In certain high-value or specialized applications, the development and use of alternative materials, like aluminum or stainless steel tubes, are accelerating. While this brings new competition, it also forces copper tube manufacturers to emphasize their unique advantages: superior thermal conductivity, antibacterial properties, and reliability. By focusing on these benefits, companies can retain a competitive edge and serve markets where copper’s unique properties remain essential.

3. Exploring High-Value-Added Markets

As copper tube manufacturerslook to reduce their reliance on traditional markets, they are turning to emerging sectors with higher profit margins and less price sensitivity. These include the development of ultra-pure copper tubes for semiconductor manufacturing, high-efficiency cooling systems for green buildings, and thermal management systems for new energy vehicles. These blue ocean markets offer opportunities for significant growth, with the potential to generate higher revenues and long-term stability.

4. Circular Economy and Green Development

The growing emphasis on sustainability has made copper recycling more economically viable. The 100% recyclability of copper significantly enhances the economics of recycling scrap copper, benefiting the recycled copper industry. Leading copper tube manufacturers are building a "production-use-recycling-reproduction" closed-loop system to reduce reliance on primary copper ores. This not only lowers costs but also aligns with global trends toward green development and a circular economy.

Industry Outlook for Copper Tube Manufacturers: Resilient Development and Value Creation

Industry analysts predict that copper prices are likely to remain high and volatile in the short term. This environment will require copper tube manufacturers to develop stronger risk management strategies and cost-pass-through capabilities. However, the longer-term impact of these price fluctuations could accelerate industry consolidation, with companies lacking core competitiveness being gradually eliminated. On the other hand, copper tube manufacturers that prioritize technology, management, and sustainable development will emerge stronger from this crisis.

A Stress Test and Transformation Opportunity

"This is both a stress test and a transformation opportunity," said a senior industry analyst. "The copper tube industry is shifting from extensive growth reliant on scale expansion to intensive growth driven by technological innovation and value creation. In the future, companies capable of providing high-performance, customized, and green solutions will hold a more favorable position in the market."

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文