Only a thin protective layer makes the difference: Why do some copper tubes last 15 years, while others corrode and leak after only 3 years?

“Both are copper tubes used in seawater desalination equipment, but the products we treated with conventional pickling and passivation showed pitting corrosion and leakage in less than 3 years in the marine environment; while the competitor's product, treated with vacuum ion plating technology, has a service life of over 15 years, and its unit price is 30% higher than ours.” Mr. Liu, the technical director of a copper alloy tube company in Qingdao, held up two sections of discarded and intact copper tubes, revealing the hidden value of surface treatment technology. Surface treatment, as the final step in copper tube production, may seem like a simple auxiliary operation of "rust removal and coating," but it directly determines the product's corrosion resistance, wear resistance, and service life, and further impacts its market positioning and added value. Currently, most domestic copper tube manufacturers still rely on traditional surface treatment processes such as pickling and ordinary passivation, making their products unsuitable for demanding environments such as marine, chemical, and high-end water treatment; a few companies, however, have upgraded their refined surface treatment technologies, allowing their copper tubes to maintain stable performance in extreme environments and easily capture the high-end market. This thin "protective film" is becoming a core detail that differentiates the competitiveness of copper tube products, and it also holds the key to the industry's upgrade from "qualified" to "high-quality."

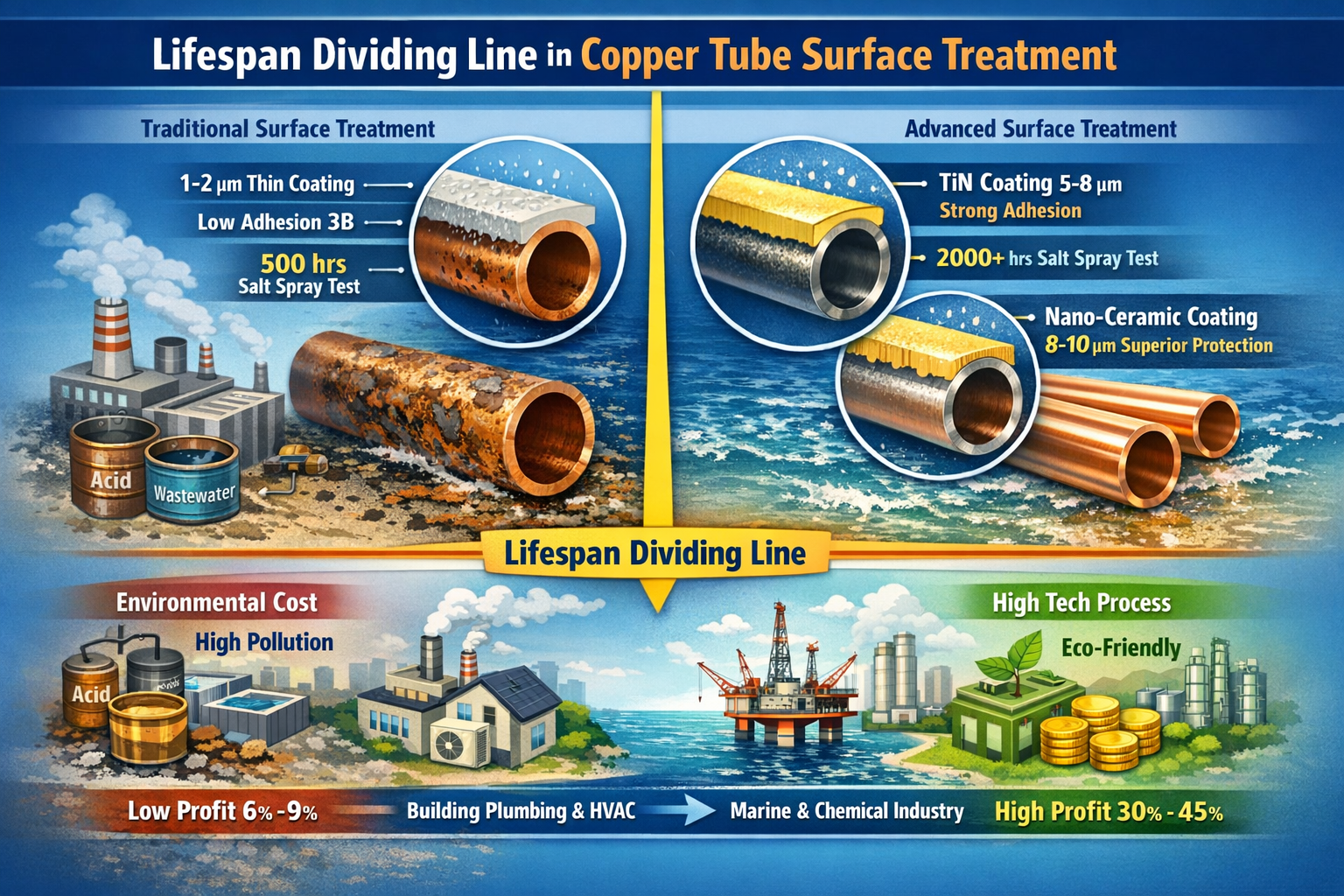

Detailed Analysis: The "Lifespan Dividing Line" in Surface Treatment

The core value of copper tube surface treatment lies in forming a protective layer on the surface through physical or chemical means, isolating it from corrosive sources such as air, moisture, and acid-base media, while simultaneously optimizing surface roughness and improving product compatibility. The protective layers formed by different processes vary significantly in thickness uniformity, adhesion, and corrosion resistance, ultimately directly impacting product lifespan. Data from accelerated aging tests conducted by the China Nonferrous Metals Processing Industry Association shows that: Copper tubes using the traditional pickling and passivation process have a protective layer thickness of only 1-2 μm, an adhesion rating of 3B (easily detached), and an accelerated corrosion test life of approximately 500 hours in a 5% salt water environment, corresponding to an actual service life of 3-5 years; Copper tubes using the vacuum ion plating (TiN coating) process have a protective layer thickness of 5-8 μm, an adhesion rating of 1B (strong adhesion), and a test life exceeding 2000 hours in the same salt water environment, with an actual service life of over 15 years; while copper tubes using the electrochemical polishing + nanoceramic coating process offer even better protective performance, with an actual service life exceeding 20 years, perfectly suited for highly corrosive chemical environments.

From the perspective of application scenarios and added value, the differences in surface treatment processes directly determine the market level of the product. Copper tubes used in conventional building plumbing and ordinary air conditioning and refrigeration systems have low requirements for corrosion resistance, and traditional pickling and passivation processes are sufficient. The gross profit margin for these products is only 6%-9%. However, copper tubes used in marine engineering, chemical pipelines, and high-end water purification equipment need to withstand harsh environments such as salt, alkali, and acid for a long time, requiring refined surface treatment processes. These products can achieve a gross profit margin of 30%-45%, and the market demand is stable. The procurement standards of a marine engineering equipment manufacturer show that their matching copper tubes must pass a 1000-hour neutral salt spray test without corrosion, and the surface roughness must be ≤Ra0.2μm. Only 3-5 domestic companies using high-end surface treatment processes can meet these standards; most companies relying on traditional processes miss out on these orders.

(This image was generated by AI.)

From a practical business perspective, the differences in surface treatment processes are also reflected in environmental costs and production efficiency. Traditional pickling and passivation processes rely on strong acids and bases, which not only generate a large amount of wastewater containing heavy metals, resulting in high environmental treatment costs (approximately 300 yuan per ton of copper tube), but also suffer from problems such as uneven surface corrosion and protective layer peeling, requiring frequent maintenance. Fine-tuned processes such as vacuum ion plating and electrochemical polishing utilize zero-emission technologies or low-pollution reagents, reducing environmental treatment costs to 80-120 yuan per ton of copper tube. Furthermore, these processes offer better uniformity and adhesion of the protective layer, eliminating the need for additional maintenance. Although the initial equipment investment is higher, the long-term overall cost is lower, and the product's premium pricing potential is significantly enhanced.

|

Surface treatment process |

Core equipment/reagents |

Protective layer parameters |

Corrosion resistance (salt spray test) |

Applicable scenarios |

Total cost (yuan/ton) |

Product premium rate |

|

Traditional pickling and passivation |

A mixture of hydrochloric acid and nitric acid, used in an acid pickling tank. |

Thickness: 1-2 μm, Adhesion: 3B, Roughness: Ra 0.8-1.2 μm |

≤500 hours, susceptible to pitting corrosion. |

General building plumbing and drainage, household air conditioning copper tube |

450-550 |

0%-5% |

|

Vacuum ion plating (TiN coating) |

Vacuum ion plating machine, titanium target material |

Thickness: 5-8 μm, Adhesion: 1B, Roughness: Ra 0.2-0.4 μm |

1500-2000 hours, no corrosion. |

Copper tubes for marine engineering and shipbuilding applications. |

800-900 |

25%-30% |

|

Electrochemical polishing + nanocrystalline ceramic coating |

Electrochemical polishing tank, nano-ceramic coating agent |

Thickness: 8-10 μm, Adhesion: 1A, Roughness: Ra ≤ 0.2 μm |

≥2000 hours, extremely strong corrosion resistance |

Chemical pipelines, high-end water purification equipment, copper tubes |

1200-1500 |

35%-45% |

Table 1: Comparison of Key Parameters and Application Value of Three Surface Treatment Processes

Detailed breakdown: The three core issues behind the differences in surface treatment processes.

What seems like a subtle difference in "protective layer thickness" actually reflects a significant gap in capabilities across three core areas: equipment technology, process control, and reagent formulation. In-depth factory investigations reveal that the gap in surface treatment processes among domestic companies is not simply a matter of equipment selection, but rather a difference in the ability to precisely control and optimize process details. These three key issues collectively lead to the divergence in product corrosion resistance and added value.

Problem 1: Equipment and technological barriers; domestic equipment lacks sufficient precision and stability.

The core technologies of sophisticated surface treatment equipment have long been monopolized by German and Swiss companies. Although domestic equipment manufacturers can produce basic coating and polishing equipment, there are significant gaps in coating uniformity control, ion beam intensity adjustment, and polishing precision. Imported vacuum ion plating machines utilize multi-target collaborative sputtering technology, coupled with a laser thickness measurement system, which can control the protective layer thickness error within ±0.1μm and achieve 100% coating coverage; while similar domestic equipment mostly uses single-target sputtering, with thickness measurement primarily relying on manual inspection, resulting in a thickness error of up to ±0.5μm. This often leads to problems such as incomplete coating and uneven thickness, failing to meet the requirements of high-end products.

More importantly, the intelligent control system accompanying the imported equipment enables precise digital control of process parameters. It automatically optimizes parameters such as ion beam intensity, coating time, and polishing current for different materials and specifications of copper tubes. In contrast, domestic equipment often lacks intelligent control functions, relying entirely on worker experience for parameter adjustment, resulting in poor consistency in the performance of the protective layer across different batches of products. "For copper tubes of the same specifications, those processed with domestic equipment sometimes pass the salt spray test for 800 hours, while others only last 400 hours. We simply can't deliver high-end orders in bulk," said Engineer Liu. He added that the company had tried to debug the vacuum ion plating process using domestic equipment, but after two months, they still couldn't achieve stable results, ultimately forcing them to spend over 12 million yuan on imported equipment.

Problem 2: Crude process control, lacking standardized and detailed management.

The precise control of surface treatment processes relies on standardized operations throughout the entire process. However, most small and medium-sized copper tube enterprises in China still rely on extensive production methods, lacking a systematic process control system. For example, in traditional pickling and passivation processes, subtle changes in acid concentration, pickling temperature, and passivation time can affect the adhesion of the protective layer. However, most companies lack clear parameter control standards; acid concentration is judged by workers' visual inspection, and temperature fluctuations can reach ±5℃, leading to unstable protective layer performance. In the electrochemical polishing stage, electrode spacing and current density affect surface roughness, but most companies lack fixed standards, relying entirely on workers' experience for adjustments, resulting in roughness deviations of up to ±0.3μm within the same batch of products.

In contrast, companies employing refined processes have established a standardized control system throughout the entire process. From real-time monitoring of acid concentration and digital control of plating parameters to laser thickness measurement and adhesion testing of the finished protective layer, each step has clear parameter standards and testing procedures, and all data is traceable throughout the process. Process documents from a high-end copper tube company show that its electrochemical polishing process requires the current density to be stable at 20-22 A/dm², the temperature controlled at 45±1℃, and the acid concentration checked every 10 minutes to ensure consistent surface roughness and qualified protective layer performance.

Problem 3: Outdated reagent formulations; difficulty in balancing environmental protection and performance.

The surface treatment reagent formula directly determines the performance and environmental friendliness of the protective layer. However, most domestic companies still use traditional reagent formulas, making it difficult to balance corrosion resistance and environmental requirements. Traditional pickling and passivation processes use a high-concentration mixture of hydrochloric acid and nitric acid, which can quickly remove surface oxide scale, but is highly corrosive, easily leading to microcracks on the copper tube surface, reducing product strength. Furthermore, wastewater treatment is difficult and costly; while domestically developed refined treatment reagents have improved environmental performance, they lag behind imported reagents in terms of coating adhesion and corrosion resistance. Imported nanoceramic coating agents can form a dense protective film on the copper tube surface, with acid and alkali corrosion resistance more than twice that of domestic reagents.

At the same time, most companies lack the ability to optimize reagent formulations and cannot adjust reagent components according to downstream needs. For example, to address the high-salt corrosion characteristics of marine environments, specialized corrosion-resistant factors need to be added to coating reagents. However, domestic companies struggle to accurately control the addition ratio, only able to copy general formulas, resulting in significantly reduced protective effects. In contrast, imported reagent manufacturers can customize formulations according to customer needs and provide exclusive process solutions to ensure product suitability for specific harsh environments.

The path to breaking the deadlock: An upgrade path from "crude processing" to "precise protection" in manufacturing processes.

While often overlooked compared to core production processes, upgrades to surface treatment technologies, despite requiring relatively low investment, can significantly boost product added value and become a key factor for companies to capture the high-end market. For domestic copper tube companies, there's no need to blindly pursue imported equipment and reagents; instead, they can gradually achieve refined surface treatment through gradual equipment upgrades, standardized process control, and reagent formula optimization, thus breaking down the invisible barriers to the high-end market.

Path 1: Upgrade equipment in stages, balancing cost and performance requirements.

Companies can choose tiered equipment upgrade solutions based on their product positioning. For small and medium-sized enterprises (SMEs) with limited capital and focusing on conventional products, existing pickling equipment can be modified by adding automatic acid concentration monitors and temperature control systems, optimizing the pickling and passivation processes. This controls the protective layer thickness error to within ±0.3μm, meeting low-to-medium-end corrosion resistance requirements. The modification cost is only 1/15 of that of imported equipment. For companies targeting the mid-range market, domestically produced mid-range vacuum coating equipment can be purchased, combined with imported core thickness measurement systems, ensuring stable protective layer performance while controlling costs. For companies in the high-end market, targeted procurement of imported precision equipment can achieve ultimate control of the protective layer, offsetting equipment costs through product premium pricing.

The transformation practices of a medium-sized copper tube company in Ningbo are highly instructive. The company invested 800,000 RMB to equip its existing pickling and passivation production line with an automatic temperature control and concentration monitoring system, optimizing the passivation reagent formula. This improved the protective layer adhesion from 3B to 2B, and increased the salt spray test life from 500 hours to 800 hours, successfully entering the mid-range marine equipment market. The product premium reached 15%, and the return on investment exceeded 180%.

Path 2: Establish a standard system to regulate and control all process details.

Companies should abandon extensive production methods and establish a standardized control system for surface treatment processes. They should identify key control points in each stage, such as pickling, polishing, coating, and testing, and develop clear parameter standards and operating procedures, forming standardized operating procedures (SOPs). For example, clearly defining core parameters such as pickling time, acid concentration, and coating temperature for different copper tube materials ensures consistent operation. Simultaneously, they should strengthen process monitoring, introducing laser thickness gauges and adhesion testers to conduct sample testing of the protective layer thickness, roughness, and adhesion of each batch of products, promptly identifying problems and adjusting the process.

Companies should also strengthen worker training, enabling workers to master parameter adjustment, equipment maintenance, and testing methods, rather than solely relying on experience. One company, through establishing a standardized system and training mechanism, reduced the product defect rate in the surface treatment process from 8% to 1.5%, and improved the consistency of protective layer performance by 60%.

Path 3: Optimize reagent formulations, considering both environmental protection and corrosion resistance.

Companies can optimize surface treatment reagent formulations through independent research and development and collaborative R&D. For traditional process companies, they can gradually reduce acid concentration, add corrosion inhibitors and stabilizers to reduce the generation of microcracks on the copper tube surface, while also reducing wastewater treatment costs. For companies with sophisticated processes, they can collaborate with universities and research institutions to develop specialized reagents adapted to specific scenarios, such as developing high salt-resistant coating reagents for marine environments and acid-base resistant reagents for chemical industry scenarios, thereby enhancing the targeted competitiveness of their products.

In addition, companies can adopt the "imported reagents + domestically developed adaptation" model. While using imported reagents for core components, they can independently formulate auxiliary components, balancing performance and cost. For example, one company uses imported products for the core ceramic factors in its nano-ceramic coating process, while independently developing the auxiliary components. This not only guarantees corrosion resistance but also reduces reagent costs by 30%.

Adding value through meticulous details, and superior surface finishing techniques underpin high-end competitiveness.

A mere "protective film" makes all the difference in product lifespan and added value. This detail reflects the core logic behind the transformation of China's copper tube industry from "scale priority" to "quality priority"—the competition in high-end manufacturing often lies in seemingly insignificant finishing processes. Surface treatment, precision testing, and packaging protection, seemingly auxiliary steps, are crucial for improving product stability and extending service life, and are also the invisible levers for companies to break through low-end competition and seize high-end markets.

For Chinese copper tube manufacturers, it's not necessary to blindly pursue upgrades of core production equipment. By focusing on detailed processes such as surface treatment, and through equipment modification, standardized management, and formula optimization, they can improve product competitiveness at a lower cost and achieve a doubling of added value. When more and more companies begin to pay attention to refining these "hidden processes," the Chinese copper tube industry can truly escape the predicament of "low-price competition," transforming from a major production country to a manufacturing powerhouse, and establishing a firm foothold in the global high-end supply chain.

Product Category

Content

- Detailed Analysis: The "Lifespan Dividing Line" in Surface Treatment

- Detailed breakdown: The three core issues behind the differences in surface treatment processes.

- The path to breaking the deadlock: An upgrade path from "crude processing" to "precise protection" in manufacturing processes.

- Adding value through meticulous details, and superior surface finishing techniques underpin high-end competitiveness.

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文