CW024A Copper Tube: Properties, Applications, and Benefits

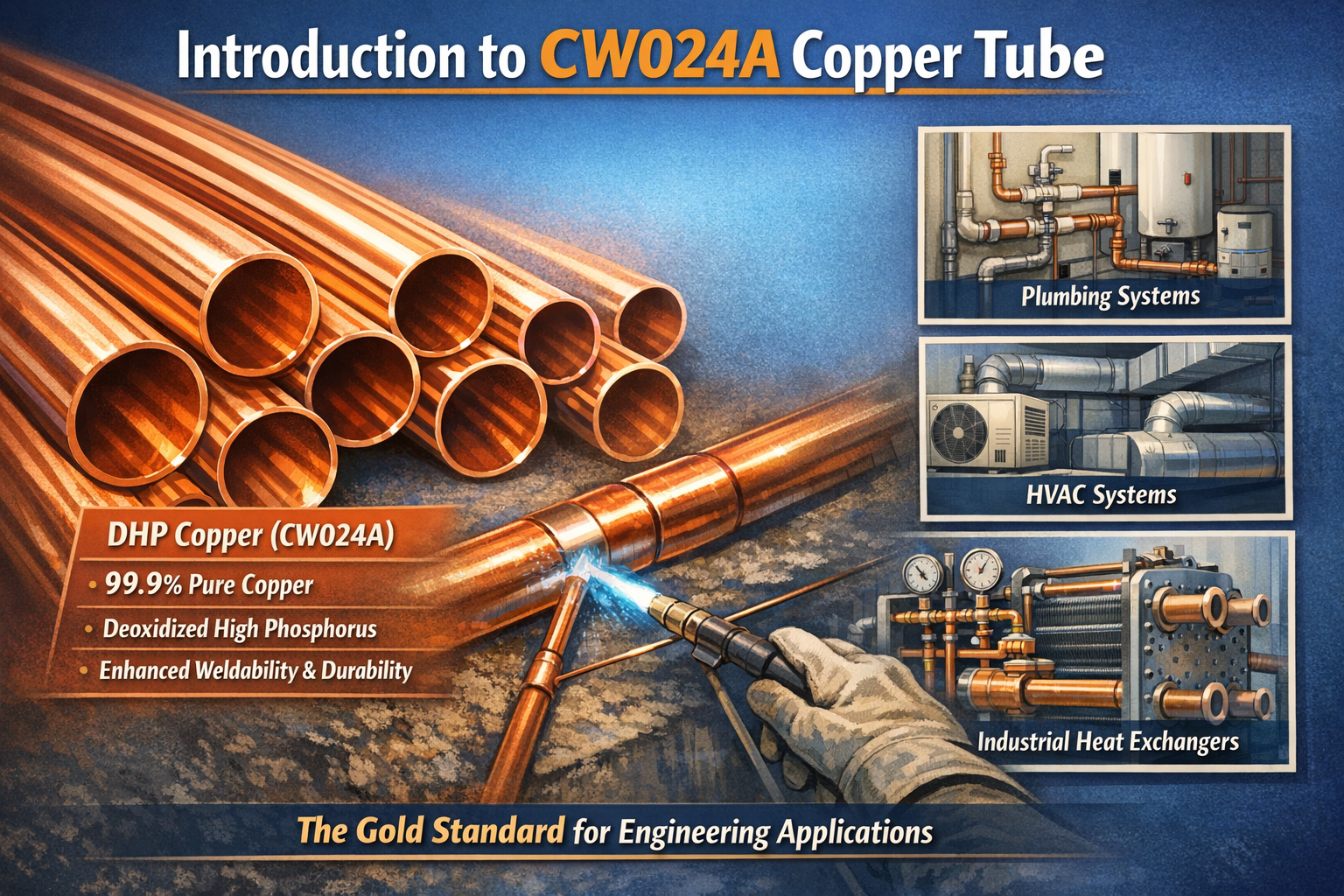

Introduction to CW024A Copper Tube

In the world of metallurgy and industrial engineering, CW024A is more than just a code—it is the industry standard for high-quality copper piping. Specifically known as DHP Copper (Deoxidized High Phosphorus), CW024A is a material engineered to overcome the historical limitations of pure copper, particularly regarding weldability and long-term durability.

Characterized by its minimum copper content of 99.9%, this alloy is "deoxidized" through the strategic addition of phosphorus. This small but vital chemical adjustment prevents the material from becoming brittle when heated, making CW024A the "gold standard" for applications requiring brazing, welding, or intricate bending.

Whether you are looking into domestic plumbing systems, high-pressure HVAC (Heating, Ventilation, and Air Conditioning) units, or complex industrial heat exchangers, understanding the unique characteristics of CW024A is essential for ensuring system integrity and efficiency. In this guide, we will dive deep into why this specific alloy remains the preferred choice for engineers and contractors worldwide.

(This image was generated by AI.)

Composition and Properties

The reliability of CW024A copper tubes stems from a precise chemical balance. Unlike "tough pitch" copper (CW004A), which contains oxygen, CW024A is deoxidized to ensure it remains stable under the high temperatures of a welder's torch.

Chemical Composition

According to the EN 12449 and EN 1057 standards, the chemical makeup of CW024A is strictly controlled:

- Copper (Cu): Minimum 99.90%

- Phosphorus (P): 0.015% to 0.040%

The phosphorus acts as a "scavenger," removing oxygen during the melting process. This prevents hydrogen embrittlement, a phenomenon where steam forms inside the metal during welding, leading to internal cracks and catastrophic failure.

Physical and Mechanical Properties

The performance of the tube varies based on its temper (material status). In the European system, these are designated by the letter "R" followed by the minimum tensile strength.

| Property | R220 (Soft/Annealed) | R250 (Half-Hard) | R290 (Hard) |

| Tensile Strength (Rm) | ≥220MPa | ≥250MPa | ≥290MPa |

| Yield Strength (Rp0.2) | ≈40 -100MPa | ≥150MPa | ≥250MPa |

| Elongation (A5) | ≥40% | ≥15% | ≥3% |

| Hardness (HV) | 40 – 70 | 75 – 100 | ≥100 |

Key Performance Characteristics

- Thermal Conductivity: At approximately 305 W/(m·K), it offers excellent heat transfer, though slightly lower than oxygen-free copper due to the phosphorus content.

- Electrical Conductivity: Roughly 80% IACS (International Annealed Copper Standard). While good, it is primarily chosen for thermal and mechanical use rather than high-end electrical conductivity.

- Corrosion Resistance: It forms a stable, protective "patina" (oxide layer) when exposed to water and oxygen, which shields the metal from further degradation.

Why "Tempers" Matter

When sourcing CW024A, the temper is as important as the alloy itself. If you are installing a residential underfloor heating system, you would choose R220 (Soft) because it can be easily coiled and bent. For straight, rigid vertical risers in a building, R290 (Hard) is preferred for its structural strength.

Manufacturing and Standards

The production of CW024A copper tubes is a journey from high-heat casting to precision cold-drawing. Because these tubes often carry high-pressure refrigerants or potable water, there is zero margin for structural flaws.

The Manufacturing Process: Seamless Production

Unlike welded tubes, CW024A is typically manufactured as a seamless tube. This eliminates the "weak link" of a longitudinal seam.

- Melting and Casting: High-purity copper is melted, and phosphorus is added to "deoxidize" the melt. It is then cast into solid billets.

- Extrusion: The billet is heated and forced through a die to create a hollow "mother tube."

- Cold Drawing: The tube is pulled through a series of smaller dies at room temperature. This process achieves the precise wall thickness and diameter required while also "work-hardening" the metal to the desired temper (e.g., R250 or R290).

- Annealing: If a "Soft" (R220) temper is needed, the tube is placed in a furnace for controlled heating and cooling to restore flexibility.

Key Industry Standards

To ensure global compatibility and safety, CW024A must adhere to specific European (EN) standards. When sourcing, you will most commonly see:

- EN 1057: The standard for copper tubes used in water and gas applications (plumbing and heating). It specifies wall thicknesses and dimensions.

- EN 12735-1: Specifically for Air Conditioning and Refrigeration (ACR). These tubes have higher requirements for internal cleanliness to prevent oil contamination in HVAC systems.

- EN 13348: The strict standard for Medical Gas systems, requiring extremely low carbon content on the internal surface.

Quality Control and Testing

To meet these standards, manufacturers perform several non-destructive tests:

- Eddy Current Testing: An electromagnetic test to detect microscopic cracks or pinholes in the tube wall.

- Hydrostatic Testing: Pressurizing the tube with water to ensure it doesn't burst under extreme load.

- Dimensional Checks: Using micrometers to verify that the wall thickness is consistent (crucial for high-pressure safety).

The "Cleanliness" Factor

A key differentiator in CW024A manufacturing is internal cleanliness. For HVACR applications, even a tiny speck of carbon or dust inside the tube can clog an expansion valve or damage a compressor. This is why many CW024A tubes are capped at both ends immediately after production.

Applications of CW024A Copper Tube

CW024A is a highly versatile alloy. While you might find it in a simple kitchen sink setup, it is equally at home in high-tech industrial cooling systems.

Plumbing and Potable Water Systems

This is the most common use for CW024A (specifically under the EN 1057 standard).

- Safe Drinking Water: Copper is naturally biostatic, meaning it inhibits the growth of bacteria (like Legionella).

- Corrosion Resistance: It handles both hot and cold water cycles without degrading or leaching harmful chemicals into the water supply.

- Durability: A properly installed CW024A plumbing system can last 50 to 100 years.

HVAC and Refrigeration (ACR)

In the HVACR industry, CW024A is prized for its thermal conductivity and ability to handle high-pressure refrigerants.

- Air Conditioning Units: It acts as the conduit for refrigerant gas. Its seamless nature is critical here to prevent leaks of expensive and environmentally sensitive gases.

- Heat Exchangers: Because it transfers heat so efficiently, it is used in the coils of both evaporators and condensers.

- Cleanliness: Under the EN 12735-1 standard, these tubes are delivered with sealed ends to ensure the interior is bone-dry and oil-free.

Industrial and Engineering Applications

Beyond the home, CW024A serves heavy industry:

- Solar Thermal Panels: Used in the absorber plates and manifolds of solar water heaters due to its ability to soak up and transfer solar heat rapidly.

- Medical Gas Pipelines: Under the EN 13348 standard, CW024A is the only choice for delivering oxygen and anesthetic gases in hospitals, where internal purity is a matter of life and death.

- Fuel and Oil Lines: Its resistance to vibration and ease of flaring make it ideal for hydraulic and fuel lines in machinery.

Sustainable Construction (Renewables)

As the world shifts toward "green" energy, CW024A is seeing a surge in:

- Geothermal Heating: The tubes are buried underground to exchange heat with the earth.

- District Heating: Large-scale insulated copper piping networks that heat entire neighborhoods.

Why not use plastic?

While PEX or PVC are cheaper, engineers choose CW024A for these applications because it doesn't melt in a fire, doesn't give off toxic fumes, is oxygen-impermeable (preventing rust in boilers), and is 100% recyclable.

Advantages of Using CW024A Copper Tube

Choosing CW024A isn't just about following tradition; it’s about the unique technical "edge" that phosphorus-deoxidized copper provides over other metals and plastics.

Exceptional Corrosion Resistance

Copper is a "noble" metal, meaning it is naturally resistant to the elements.

- The Patina Effect: When exposed to water and air, CW024A forms a stable protective oxide layer (the "patina"). This layer acts as a shield, preventing deep corrosion and "pitting" that often plagues lower-quality alloys or steel.

- Chemical Stability: It is highly resistant to most organic compounds and can withstand the harsh chemicals often found in domestic water treatments.

Superior Thermal Efficiency

With a thermal conductivity of approximately 305 W/(m·K), CW024A is a master of heat transfer.

- Energy Savings: In HVAC and heating systems, copper allows for faster heat exchange. This means your boiler or air conditioner doesn't have to work as hard, leading to lower energy bills and a smaller carbon footprint.

- Compact Design: Because copper is so efficient at transferring heat, engineers can use smaller, thinner tubes to achieve the same cooling or heating effect as much larger pipes made of other materials.

Ease of Fabrication and Joining

This is where the "Phosphorus-Deoxidized" (DHP) nature of CW024A truly shines.

- Brazing & Welding: Because the oxygen has been removed, CW024A can be brazed or welded without the risk of hydrogen embrittlement. This ensures high-strength joints that won't crack under pressure.

- Formability: CW024A is highly ductile. It can be bent into complex shapes (especially in the R220 soft temper) without kinking or thinning out dangerously, reducing the need for expensive elbow fittings.

100% Recyclability and "Green" Credentials

In an era of sustainable building, CW024A is an environmental champion.

- Infinite Lifecycle: Copper can be recycled over and over again with zero loss in quality.

- Value Retention: Unlike plastic, which often ends up in a landfill, scrap copper has high monetary value, making the "end-of-life" of a building's plumbing system a profitable asset rather than a waste problem.

Health and Safety

- Antimicrobial Surface: Copper surfaces naturally kill of bacteria within two hours of contact. This makes CW024A a safer choice for potable water systems compared to plastic pipes, which can sometimes harbor "biofilms."

- Fire Safety: Copper has a high melting point (). It does not burn, does not support combustion, and does not release toxic smoke during a building fire.

The Professional’s Verdict

CW024A offers a "fit-and-forget" peace of mind. While the initial material cost might be higher than synthetic alternatives, the combination of durability, ease of installation, and zero maintenance makes it the most cost-effective solution over the life of a building.

Comparison with Other Copper Alloys

While CW024A is the most common alloy for tubing, it exists alongside other grades like CW004A (ETP) and CW008A (OF). Understanding the subtle differences in their chemistry is key to selecting the right material for your project.

CW024A vs. CW004A (Electrolytic Tough Pitch - ETP)

CW004A is the most common grade for electrical applications (busbars, wires) because of its incredibly high conductivity. However, it contains a small amount of oxygen.

- The Welding Trap: If you try to weld or brazed CW004A, the oxygen reacts with hydrogen in the flame to cause hydrogen embrittlement. The joints will look fine but will be brittle and prone to cracking.

- The CW024A Advantage: Because CW024A is phosphorus-deoxidized, it is perfectly weldable. While its electrical conductivity is slightly lower ( vs IACS), it is the only safe choice for pressurized plumbing and HVAC systems.

CW024A vs. CW008A (Oxygen-Free - OF)

CW008A is "Oxygen-Free" copper. It is very pure and has no residual deoxidants like phosphorus.

- Performance: CW008A has higher electrical conductivity than CW024A and is also safe for welding.

- The Cost Factor: CW008A is much more expensive to produce.

- The CW024A Advantage: For 99% of mechanical and plumbing applications, CW024A provides the same welding benefits as Oxygen-Free copper but at a significantly lower price point.

Summary Comparison Table

| Feature | CW024A (DHP) | CW004A (ETP) | CW008A (OF) |

| Common Use | Tubes, HVAC, Plumbing | Electrical Wiring, Busbars | High-end Audio, Electronics |

| Weldability | Excellent | Poor (Embrittlement risk) | Excellent |

| Conductivity | Moderate (~80% IACS) | Maximum (100% IACS) | High (>100% IACS) |

| Cost | Economical for Tubing | Lowest | Highest |

When to Choose CW024A

You should specify CW024A whenever your project involves:

- Brazing or Welding: Any joint involving a torch.

- Pressure: Carrying gases (refrigerants) or liquids (water).

- Complex Bending: Where you need the material to remain ductile after being worked.

Pro Tip: Check the Stamp

Most reputable CW024A tubes will be laser-etched or stamped with the alloy code and the standard (e.g., EN 1057 CW024A). If you see "ETP" or "CW004A" on a tube intended for high-pressure HVAC, stop the installation—that material is not designed for those stress levels.

Installation and Maintenance

Installing CW024A requires a mix of traditional craftsmanship and modern precision. Because this alloy is deoxidized, it is exceptionally forgiving during the joining process, but there are still "golden rules" to follow.

Proper Installation Techniques

Depending on the application (Plumbing vs. HVAC), there are three primary ways to join CW024A:

- Brazing and Soldering: Since CW024A is phosphorus-deoxidized, it is ideal for high-temperature brazing.

- Tip: Use a nitrogen purge when brazing HVAC lines to prevent "black oxide" scale from forming inside the tube, which can clog sensitive valves.

- Press-Fit Systems: A modern, "flame-free" alternative. This uses a mechanical tool to crimp a fitting onto the tube. CW024A’s consistent wall thickness makes it perfect for this high-speed installation method.

- Bending: For soft (R220) or half-hard (R250) tempers, use a bending spring or mechanical pipe bender. CW024A's ductility allows for tight radiuses without the metal "necking" or thinning.

Best Practices for Maintenance

CW024A is largely "fit and forget," but it isn't invincible. To maximize its lifespan:

1. Flush the System: After installation, always flush the system with clean water. Leftover soldering flux is acidic and can cause "pitting corrosion" if left sitting in the pipe for weeks before the building is occupied.

2. Monitor Flow Velocity: To prevent "erosion-corrosion," water velocity should generally be kept below 2.0 meters per second for cold water and 1.5 meters per second for hot water.

3. Avoid Dissimilar Metals: Never connect copper directly to galvanized steel or aluminum without a "dielectric union" or brass fitting in between. This prevents galvanic corrosion, where the less noble metal is eaten away by an electrochemical reaction.

Troubleshooting Common Issues

- Green Staining: This is usually caused by slightly acidic water (low pH). Installing a water neutralizer can protect the internal "patina" of the CW024A tube.

- Water Hammer: If you hear banging sounds when valves close, it’s a pressure surge. Installing a water hammer arrestor protects the copper joints from fatigue over time.

The Professional Shortcut

When installing CW024A for Medical Gas or Refrigeration, always verify that the tube ends remained capped until the moment of installation. This preserves the internal cleanliness standard (EN 13348 or EN 12735-1) that you paid for.

Sourcing and Purchasing

Buying CW024A copper tube involves more than just checking the price per meter. To ensure the integrity of your installation, you must verify the material's origin, its temper, and its compliance with international standards.

Available Sizes and Forms

CW024A is typically available in two main formats depending on your installation needs:

- Straight Lengths (3m or 6m): Usually supplied in Hard (R290) or Half-Hard (R250) tempers. These are ideal for exposed, rigid pipework in plant rooms or commercial plumbing.

- Pancake or Level-Wound Coils (15m to 50m): Usually supplied in Soft (R220) temper. These are preferred for air conditioning lines and underfloor heating where continuous runs and manual bending are required.

Common outside diameters (OD) range from 6mm for capillary tubes up to 108mm for large-scale industrial mains, with wall thicknesses typically between 0.7mm and 3.0mm.

What to Look for in a Supplier

When selecting a vendor, use this checklist to avoid "counterfeit" or sub-standard alloys:

- Material Certification: Always ask for a Mill Test Certificate (MTR) or an EN 10204 3.1 certificate. This document proves the chemical composition (the 99.9% Cu and 0.015-0.04% P) and the mechanical strength of that specific batch.

- Permanent Markings: High-quality CW024A tubes are laser-etched or stamped with the manufacturer’s name, the alloy code (CW024A), the standard (e.g., EN 1057), and the production date. If the markings are missing or wipe off easily, the quality is suspect.

- End-Capping: For HVAC and medical applications, ensure the supplier delivers the tubes with factory-sealed ends. This prevents moisture and dust from contaminating the internal surface during transport.

Factors Affecting Price

- LME Copper Price: Like gold or oil, copper is a commodity traded on the London Metal Exchange. Prices fluctuate daily.

- Fabrication Markup: The thinner the wall or the smaller the diameter (like capillary tubes), the higher the manufacturing cost relative to the weight of the copper.

- Temper Processing: Soft (annealed) copper often costs slightly more than hard copper because of the extra heat-treatment step required at the factory.

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文