Both use the same annealing process: why is the ductility of domestically produced copper tubes 30% lower, and why do high-end orders rely entirely on imported equipment?

“Even with the same copper tube annealing process, the tensile strength of the products processed with our domestically produced equipment is consistently inconsistent, and the toughness is 30% worse than those processed with imported equipment. We simply can't take on high-end orders for semiconductors and new energy vehicles.” Zhang, a production supervisor at a precision copper tube company in Jiangsu, pointed to two annealing furnaces in the workshop, highlighting a pain point in the industry. The annealing process, as a core post-processing step in copper tube production, directly determines key performance characteristics such as toughness, hardness, and thermal conductivity. What seems like a simple "heating-cooling" operation actually holds the key to mass-producing high-end copper tubes. Currently, most small and medium-sized copper tube manufacturers in China still rely on traditional annealing equipment and empirical operations, resulting in insufficient product performance stability; a few high-end manufacturers, however, have firmly secured the high-end order market by utilizing imported precision annealing equipment and digital temperature control technology. The same copper tube raw materials, due to subtle differences in the annealing process, lead to vastly different product competitiveness. This "detail process," overlooked by most companies, is becoming an invisible barrier hindering the Chinese copper tube industry from moving towards the high-end market.

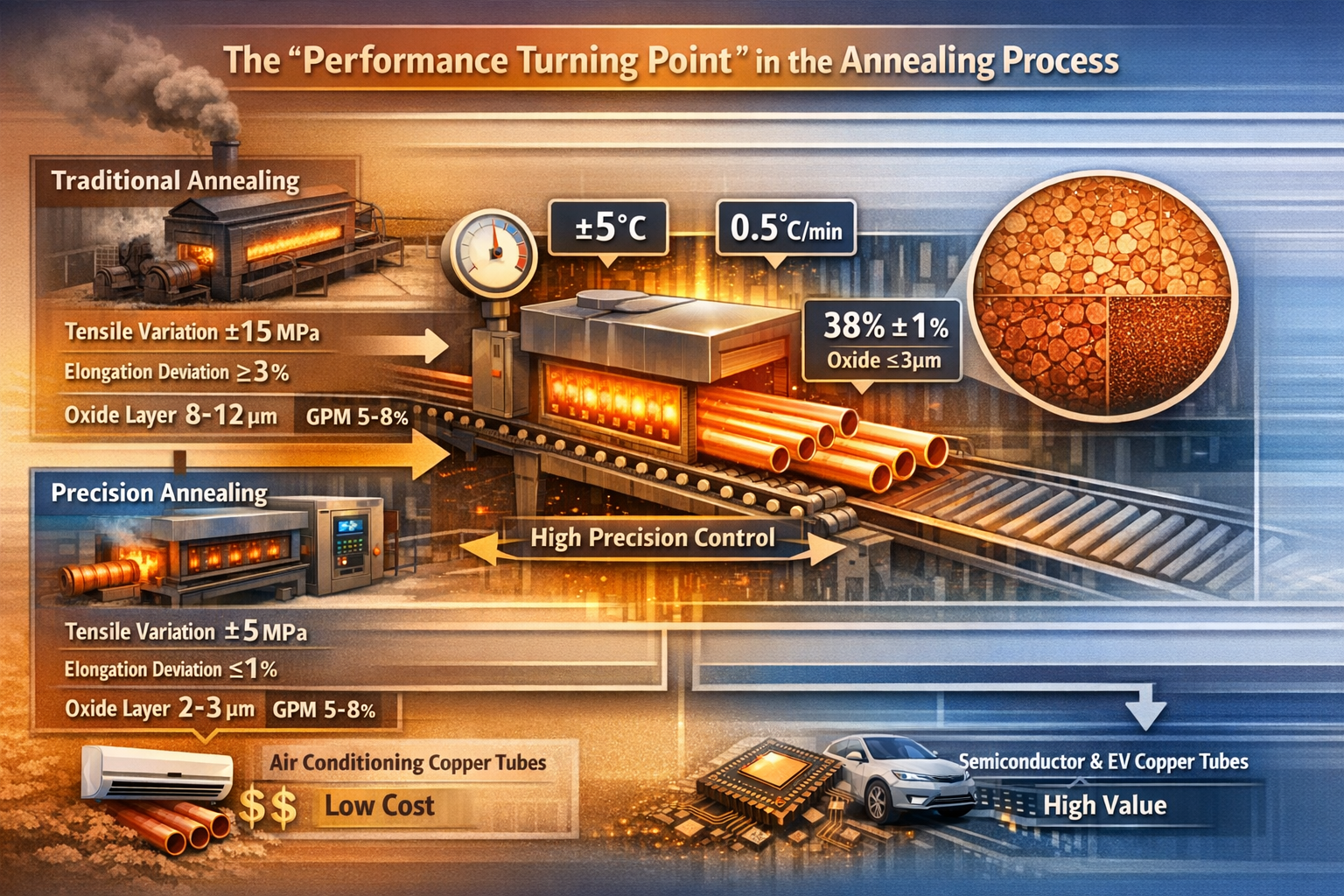

Detailed Analysis: The "Performance Turning Point" in the Annealing Process

The core of the annealing process lies in precisely controlling the heating temperature, holding time, and cooling rate to eliminate internal stresses generated during the rolling and drawing of copper tubes, and to adjust the metal's microstructure, thereby optimizing the product's mechanical properties and processing performance. While the process logic seems simple, it demands extremely high precision in parameter control—a temperature deviation exceeding ±5℃ or a cooling rate fluctuation of 0.5℃/min can lead to significant differences in the performance of the copper tubes. According to testing data from the China Nonferrous Metals Processing Industry Association, copper tubes produced using traditional annealing processes exhibit tensile strength variations of up to ±15MPa, elongation deviations exceeding 3%, and surface oxide layer thicknesses generally ranging from 8-12μm; whereas copper tubes produced using precision annealing processes have tensile strength variations controlled within ±5MPa, elongation deviations of ≤1%, and surface oxide layer thicknesses of only 2-3μm, fully meeting the stringent requirements for performance stability in high-end applications.

(This image was generated by AI.)

From the perspective of application scenarios, the differences in annealing process details directly determine the market segment of the product. Conventional copper tubes for air conditioners have lower requirements for annealing precision, and traditional processes can meet the demand; these products have a gross profit margin of only 5%-8%. However, ultra-fine copper tubes for semiconductors and thin-walled copper tubes for thermal management in new energy vehicles require not only that the annealed products meet standards for toughness and thermal conductivity, but also demand extremely high consistency in performance. Only precision annealing processes can achieve mass production, and these products can have a gross profit margin of 25%-40%. The procurement standards of a semiconductor equipment manufacturer show that the elongation of their matching copper tubes after annealing needs to be stable at 38%±1%, and the oxide layer thickness should not exceed 3μm. Only a few domestic companies using imported annealing equipment can meet this standard, while most companies relying on traditional processes miss out on high-end orders.

From a practical business perspective, the differences in annealing processes are also reflected in production costs and efficiency. Traditional annealing furnaces often use coal or oil heating, with temperature control primarily relying on manual adjustment. This not only results in high energy consumption (approximately 1200 kWh per ton of copper tube) but also leads to uneven heating and severe oxidation. Subsequent acid pickling and polishing processes are required, increasing processing costs and environmental burden. Precision annealing furnaces, on the other hand, utilize electric heating and intelligent temperature control systems, enabling precise digital control of temperature, holding time, and cooling rate. Energy consumption per ton of copper tube is reduced to below 600 kWh, and the oxide layer is thin, eliminating the need for additional processing. Although the initial equipment investment is higher, the long-term overall cost is lower, and production efficiency is increased by more than 30%.

|

Process type |

Core equipment |

Temperature control accuracy |

Product performance indicators |

Applicable scenarios |

Total cost (yuan/ton) |

|

Traditional annealing process |

Domestically produced coal-fired/oil-fired annealing furnace, manually controlled temperature. |

±8-10℃ |

Tensile strength fluctuates by ±15 MPa, elongation deviation is 3%-5%, and the oxide layer is 8-12 μm thick. |

Standard air conditioning copper tubes, building copper tubes |

800-1000 |

|

Precision annealing process |

Imported electric heating annealing furnace with digital temperature control system. |

±1-3℃ |

Tensile strength fluctuates by ±5 MPa, elongation deviation is ≤1%, and the oxide layer is 2-3 μm thick. |

Semiconductor copper tube, copper tube for new energy vehicles, copper tube for medical devices |

500-600 |

Table 1: Comparison of key parameters and applications of two annealing processes

Detailed breakdown: The three core issues behind the differences in the annealing process.

What appears to be merely a subtle difference in "temperature control accuracy" actually reflects a disparity in capabilities across three core areas: equipment technology, operating procedures, and process optimization. In-depth investigations in the workshops revealed that the differences between domestic companies in annealing processes are not simply due to the quality of the equipment, but more importantly, to their ability to control and optimize process details. These three key issues collectively lead to variations in product performance.

Problem 1: Equipment and technological barriers; domestically produced equipment lacks sufficient precision.

The core technology of precision annealing furnaces has long been monopolized by German and Japanese companies. Although domestic equipment manufacturers can produce annealing furnaces, there are significant gaps in heating uniformity, temperature control system stability, and cooling rate adjustment accuracy. Imported precision annealing furnaces utilize multi-zone independent heating modules, coupled with infrared temperature measurement and AI temperature control algorithms, allowing for real-time monitoring of the temperature of various parts of the copper tube and precise adjustment of heating power, achieving a temperature control accuracy of ±1°C. In contrast, traditional domestic annealing furnaces mostly use single-zone heating, primarily relying on thermocouples for temperature measurement, which suffers from measurement lag and large errors. Their temperature control accuracy can only reach ±8°C or higher, failing to meet the requirements of high-end products.

More importantly, the digital system accompanying the imported equipment allows for the storage, traceability, and optimization of annealing process parameters. It can automatically select the optimal process plan for copper tubes of different specifications and materials. In contrast, most domestically produced equipment lacks digital capabilities, and process parameters rely entirely on the experience of skilled workers, resulting in poor consistency in the performance of different batches of products. "For copper tubes of the same specifications, the ductility after annealing varies depending on the operator. We simply couldn't risk mass-producing high-end orders," said Engineer Zhang. He added that the company had tried to use domestically produced equipment to fine-tune the precision annealing process, but after three months, they were still unable to consistently meet customer requirements. Ultimately, they had to spend over 8 million yuan to import an annealing furnace.

Problem 2: Lack of standardized operating procedures; experience-based production makes it difficult to control details.

Precise control of the annealing process relies on standardized operating procedures, but most small and medium-sized copper tube manufacturers in China still rely on experience-based production, lacking systematic operating standards and training systems. For example, the density and placement angle of copper tubes in the furnace affect heating uniformity, but most companies lack clear loading standards, relying entirely on workers' experience for placement; the setting of the holding time is based on workers' subjective judgment of the copper tube thickness and material, rather than precise calculations and measurements, leading to inconsistent heat treatment results within the same batch of products.

In contrast, companies employing precision manufacturing processes have established standardized operating procedures for the entire process. From the spacing and angle of the copper tubes in the furnace to the heating rate, holding time, and selection of cooling medium, there are clear parameter standards, and data is recorded at every stage, enabling full traceability. At the same time, these companies provide professional training for their operators, requiring them to master skills such as temperature monitoring, parameter adjustment, and equipment maintenance, rather than simply relying on experience. Training materials from a high-end copper tube company show that its annealing process operators must undergo three months of theoretical learning and practical assessment, mastering the adjustment techniques for 12 core parameters, before they can work independently.

Problem 3: Insufficient process optimization; lack of data-driven iterative capabilities.

The annealing process is not static; it requires continuous optimization of process parameters based on changes in raw material composition, product specifications, and downstream demand. However, most domestic companies lack the data accumulation and analysis capabilities to achieve precise process iteration. For example, when there are subtle fluctuations in the purity of the raw copper, companies are unable to adjust the annealing temperature and holding time in a timely manner, leading to deviations in product performance. Similarly, for new types of thin-walled copper tubes and alloy copper tubes, they can only blindly apply traditional process parameters, making it difficult to meet the specific requirements of these products.

Companies using imported equipment leverage digital systems to accumulate a large amount of annealing process data. By analyzing the impact of different parameter combinations on product performance, they build a proprietary process database. When raw materials or specifications change, the data model can quickly optimize parameters to ensure stable product performance. For example, a semiconductor copper tube company in Suzhou, by analyzing tens of thousands of sets of annealing data, optimized a proprietary process plan for ultra-fine copper tubes of different diameters, increasing the product pass rate from 85% to 98%, and successfully entering the international semiconductor equipment supply chain.

Breaking the deadlock: The path to process upgrading from "reliance on experience" to "precise control"

While the details of the annealing process upgrade may not be as eye-catching as capacity expansion or technological research and development, they can directly enhance product competitiveness and become crucial for companies to seize high-end markets. For domestic copper tube manufacturers, there is no need to blindly pursue imported equipment; instead, they can gradually achieve precision in the annealing process through equipment upgrades, standardized operations, and data accumulation, thus breaking down the invisible barriers to high-end orders.

Path 1: Upgrade equipment gradually, balancing cost and precision requirements.

Companies can choose a tiered equipment upgrade plan based on their product positioning, avoiding blind investment. For small and medium-sized enterprises (SMEs) primarily producing conventional products and with limited capital, existing domestic annealing furnaces can be modified by adding intelligent temperature measurement modules and automatic temperature control devices, improving temperature control accuracy to ±5℃, meeting the needs of mid-to-high-end conventional products. The modification cost is only 1/10 of that of imported equipment. For companies focusing on the high-end market, they can specifically purchase imported precision annealing furnaces, combined with digital systems, to achieve ultimate precision control, while also spreading equipment costs through large-scale production.

The transformation practices of a medium-sized copper tube company in Anhui province are highly instructive. The company invested 500,000 yuan to equip its existing domestically produced annealing furnaces with infrared thermometers and PLC temperature control systems, optimizing the heating module layout. This improved temperature control accuracy from ±10℃ to ±4℃, keeping product elongation deviation within 2%. This allowed the company to successfully enter the new energy vehicle supply chain market, increasing the proportion of high-end products from 15% to 35%, and achieving a return on investment of over 200%.

Path 2: Establish a standard system to standardize operational details throughout the entire process.

Companies should abandon experience-based production and establish a standardized operating system for the annealing process. On the one hand, they should identify key control points in each stage, including loading, heating, holding, and cooling, and develop clear parameter standards and operating procedures to create standardized operating procedures (SOPs), ensuring consistent operation by every worker. On the other hand, they should strengthen worker training, combining standardized operations with process principles, so that workers not only understand how to perform the tasks but also understand the underlying reasons, enabling them to make subtle parameter adjustments based on equipment operating status and raw material variations.

At the same time, companies should establish a process quality inspection system, conducting sample testing of copper tube performance before and after annealing, recording relevant data, promptly identifying operational and parameter issues, and continuously optimizing standards. One company, by establishing an annealing process SOP and inspection system, improved product performance consistency by 40%, reduced the defect rate from 6% to 1.2%, and significantly lowered rework costs.

Path 3: Accumulate process data to achieve data-driven optimization and iteration.

Companies should prioritize the accumulation and analysis of process data, gradually building data-driven process optimization capabilities. For companies already equipped with digital equipment, systems can automatically collect data such as heating temperature, holding time, cooling rate, and product performance to establish a process database. For companies using traditional equipment, key parameters and test results can be manually recorded to gradually accumulate data resources. By analyzing the relationships between the data, the optimal combination of process parameters can be identified, and customized process solutions can be developed for different product specifications and raw material characteristics.

Furthermore, companies can strengthen cooperation with equipment manufacturers and research institutions to leverage external technological resources and optimize processes. For example, they can collaborate with universities to conduct annealing process simulation research and optimize parameters through simulation analysis; they can also work with equipment manufacturers to customize and optimize equipment functions based on the characteristics of their products, thereby improving process adaptability.

True mastery is revealed in the details; meticulous craftsmanship is what determines high-end competitiveness.

Although both processes involve annealing, they result in vastly different levels of product competitiveness. This seemingly minor detail reflects the core logic behind the transformation of China's copper tube industry from "scale expansion" to "quality improvement"—the competition in high-end manufacturing often lies in seemingly insignificant process details. Processes such as annealing, pickling, and polishing, which appear basic, are precisely the key factors limiting product performance stability and the hidden levers for companies to break through high-end barriers.

For Chinese copper tube manufacturers, there's no need to blindly pursue massive technological breakthroughs. By focusing on details such as the annealing process, and gradually improving product performance consistency through equipment upgrades, standardized operations, and data optimization, they can secure a place in the high-end market. Only when more and more companies begin to prioritize the refinement of process details can the Chinese copper tube industry truly escape the trap of low-end competition, transition from a "major producer" to a "manufacturing powerhouse," and establish a firm foothold in the global high-end supply chain.

Product Category

Content

- Detailed Analysis: The "Performance Turning Point" in the Annealing Process

- Detailed breakdown: The three core issues behind the differences in the annealing process.

- Problem 1: Equipment and technological barriers; domestically produced equipment lacks sufficient precision.

- Problem 2: Lack of standardized operating procedures; experience-based production makes it difficult to control details.

- Problem 3: Insufficient process optimization; lack of data-driven iterative capabilities.

- Breaking the deadlock: The path to process upgrading from "reliance on experience" to "precise control"

- True mastery is revealed in the details; meticulous craftsmanship is what determines high-end competitiveness.

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文