Why Fin Copper Tubes Are Becoming Essential in Refrigeration and Air Conditioning

As the world increasingly focuses on energy efficiency and sustainability, industries are constantly searching for better solutions to meet both their performance and environmental goals. In the refrigeration and air conditioning sectors, one material that has emerged as indispensable is the Fin Copper Tube. Known for its excellent heat transfer capabilities, durability, and eco-friendliness, the Fin Copper Tube is quickly becoming a preferred choice for many engineers and manufacturers in these industries.

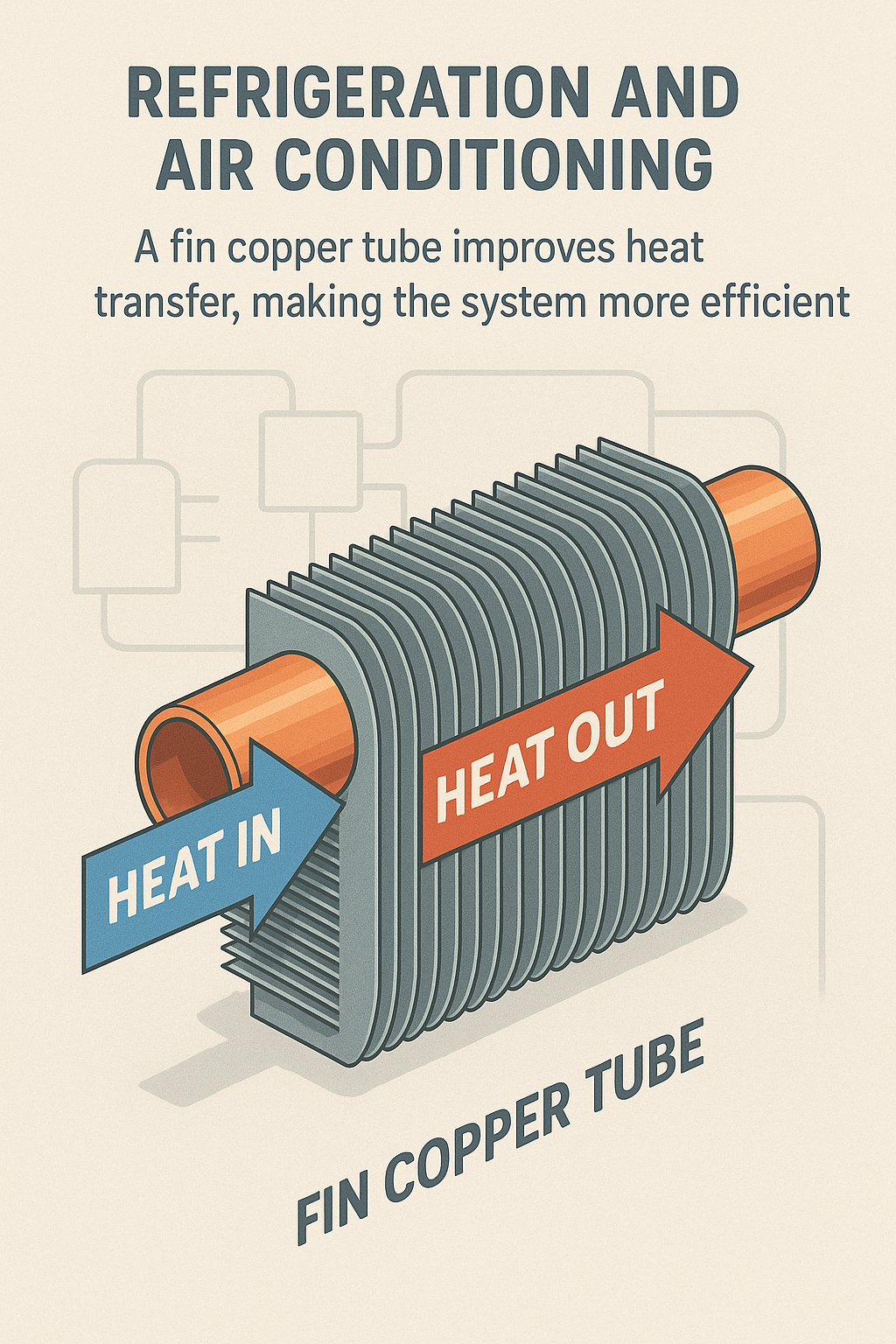

The Role of Heat Transfer Efficiency in Cooling Systems

In both refrigeration and air conditioning systems, the core task is to move heat from one location to another. A highly efficient heat exchange process is essential for the system to operate optimally. The efficiency of heat transfer plays a major role in how well these systems cool spaces or preserve perishable goods. The more effective the heat exchange, the lower the energy consumption, and the better the performance of the system.

The Fin Copper Tube is engineered to enhance this process. By adding fins to copper tubes, manufacturers increase the surface area available for heat transfer, which significantly boosts efficiency. Copper is renowned for its excellent thermal conductivity, and when combined with fins, it creates a highly effective heat exchanger. This makes Fin Copper Tubes indispensable for modern refrigeration and air conditioning applications.

Advantages of Fin Copper Tubes

Exceptional Heat Transfer Performance

One of the primary reasons for the growing popularity of Fin Copper Tubes is their remarkable heat transfer performance. Copper is one of the best conductors of heat, which means it can absorb and release heat quickly and efficiently. When copper tubes are equipped with fins, the increased surface area allows for more heat to be transferred from the refrigerant inside the tube to the surrounding environment. This enhanced heat exchange process ensures that refrigeration and air conditioning systems work more efficiently, saving energy and improving performance.

Durability and Resistance to Corrosion

Another major advantage of Fin Copper Tubes is their long-lasting durability. Copper naturally resists corrosion, which makes it ideal for systems exposed to moisture, humidity, or other environmental factors. This characteristic ensures that Fin Copper Tubes can maintain their performance over time with minimal maintenance requirements. This corrosion resistance also contributes to the overall lifespan of the refrigeration or air conditioning system, reducing long-term repair costs and ensuring consistent performance.

Environmental Sustainability

Sustainability is becoming increasingly important across all industries. Copper, as a material, is highly sustainable due to its recyclability. Copper tubes can be reused, reducing the need for new materials and minimizing waste. This makes Fin Copper Tubes an eco-friendly option for systems that aim to reduce their environmental impact. Moreover, because copper is a highly efficient conductor of heat, Fin Copper Tubes can help reduce the energy consumption of cooling systems, further contributing to sustainability efforts.

Cost-Effectiveness

Although copper may have a higher initial cost compared to some other materials, the long-term cost savings associated with Fin Copper Tubes are significant. The enhanced heat transfer efficiency means that cooling systems equipped with copper tubes use less energy, reducing electricity bills. Additionally, their durability and corrosion resistance translate to lower maintenance costs and fewer replacements. Over time, these savings make Fin Copper Tubes a more cost-effective option compared to other materials that may need to be replaced more frequently.

Table 1: Cost Comparison of Materials for Cooling Systems

| Material | Initial Cost | Lifespan (Years) | Maintenance Cost | Energy Efficiency | Recyclability |

| Fin Copper Tube | High | 15-20 | Low | Very High | 100% |

| Aluminum Tubes | Moderate | 8-12 | Moderate | High | 100% |

| Steel Tubes | Low | 10-15 | High | Moderate | Moderate |

Applications of Fin Copper Tubes in Refrigeration and Air Conditioning

The unique properties of Fin Copper Tubes make them highly suitable for various applications in both the refrigeration and air conditioning industries. Here are some of the most common uses:

Air Conditioning Systems

In air conditioning systems, Fin Copper Tubes are widely used in evaporator and condenser coils. The evaporator absorbs heat from the air inside the building, while the condenser releases the heat to the outdoor environment. The use of Fin Copper Tubes in both of these components improves the overall heat transfer efficiency, leading to better cooling performance and lower energy consumption.

Refrigeration Systems

From food storage units to industrial refrigeration systems, Fin Copper Tubes are essential in maintaining efficient temperature control. In commercial and residential refrigerators, freezers, and even industrial cooling systems, copper tubes help maintain low temperatures while minimizing energy use. Fin Copper Tubes are also used in the heat exchangers that are vital to the refrigeration cycle, ensuring that the system operates at its best.

Automotive Cooling Systems

In the automotive industry, Fin Copper Tubes are commonly found in radiators and air conditioning units. The automotive sector is constantly striving for energy-efficient solutions that improve vehicle performance while reducing emissions. By using Fin Copper Tubes in cooling systems, manufacturers can ensure that their vehicles maintain optimal engine and cabin temperatures without excessive energy consumption.

Industrial Heat Exchangers

In large-scale industrial applications, Fin Copper Tubes are frequently used in heat exchangers. These systems are designed to transfer heat from one fluid to another, and the combination of copper’s excellent conductivity and the increased surface area from the fins makes these tubes ideal for the job. Whether used in power plants, manufacturing facilities, or chemical plants, Fin Copper Tubes help keep equipment running at optimal temperatures while improving overall system efficiency.

Table 2: Applications of Fin Copper Tubes

| Application | Description | Benefits |

| Air Conditioning | Used in evaporator and condenser coils | Improved heat transfer, lower energy use |

| Refrigeration Systems | Applied in food storage, freezers, and industrial coolers | Maintains low temperature, energy-efficient |

| Automotive Cooling | Used in radiators and air conditioning units in vehicles | Enhances vehicle cooling efficiency |

| Industrial Heat Exchangers | Used in large-scale heat exchangers | High thermal efficiency, robust performance |

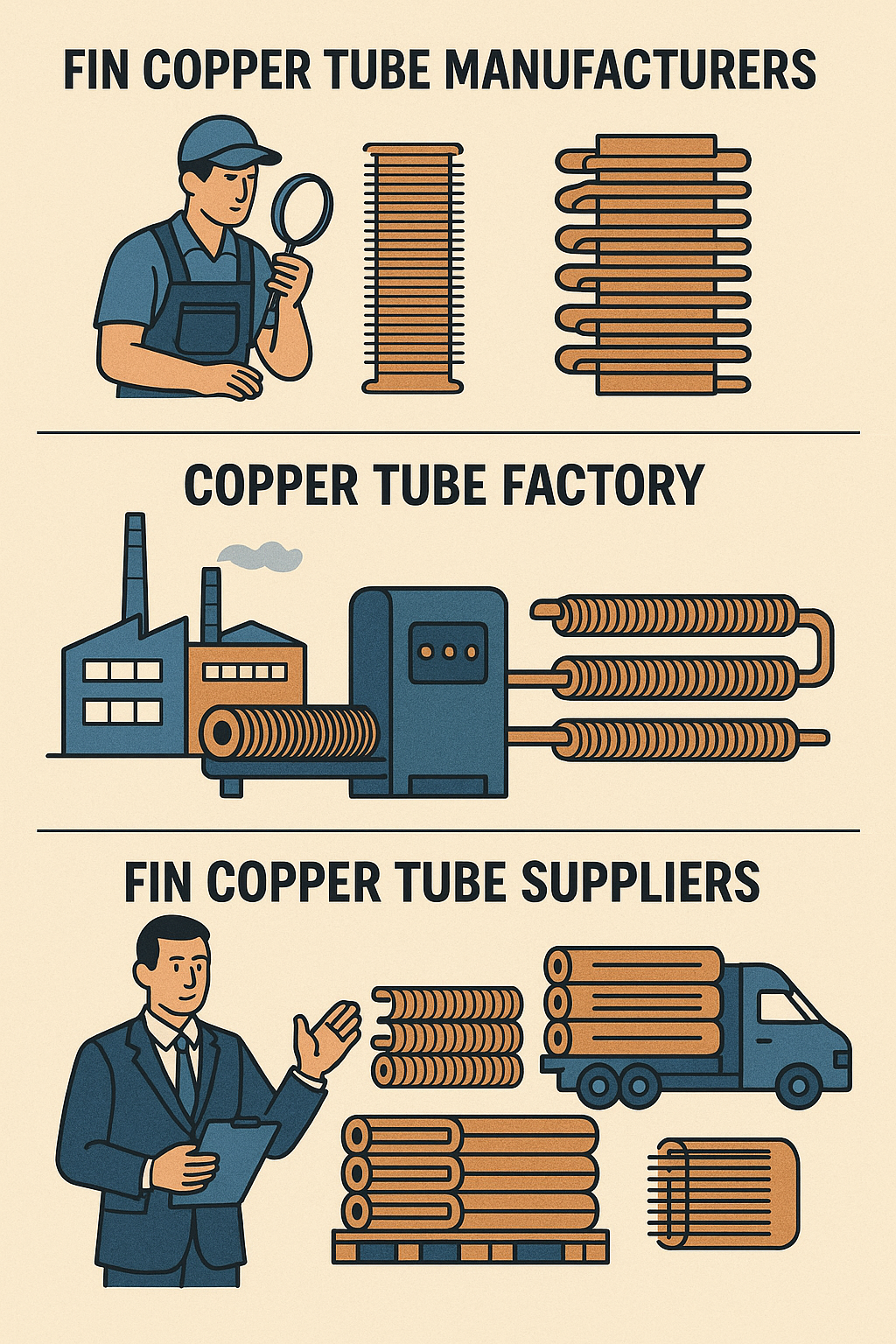

The Role of Fin Copper Tube Manufacturers and Suppliers

The growing demand for Fin Copper Tubes in the refrigeration and air conditioning industries has led to a rise in the number of Fin Copper Tube Manufacturer and Copper Tube Factory. These manufacturers and factories play a vital role in the production and distribution of Fin Copper Tubes.

Fin Copper Tube Manufacturers

Fin Copper Tube Manufacturers are responsible for producing high-quality copper tubes designed specifically for heat exchange applications. These manufacturers work with advanced production techniques to create tubes that are durable, efficient, and cost-effective. Their role in the supply chain is crucial, as they ensure that the materials meet industry standards and customer specifications.

Copper Tube Factory

Copper Tube Factory focus on mass-producing copper tubes in various sizes and configurations to meet the demands of the refrigeration and air conditioning sectors. These factories use state-of-the-art machinery to manufacture Fin Copper Tubes with precise dimensions, ensuring that each tube delivers maximum efficiency and performance. These factories also often provide custom solutions for specific applications, allowing engineers and designers to get the exact type of copper tube they need for their systems.

Fin Copper Tube Suppliers

Once the Fin Copper Tubes are manufactured, they are distributed through a network of Fin Copper Tube Suppliers. These suppliers are essential in ensuring that businesses have access to the necessary components for building or upgrading their cooling systems. Suppliers provide both small and large quantities, meeting the needs of individual consumers and large-scale industrial projects alike.

Why Choose Fin Copper Tubes from Reliable Manufacturers and Suppliers?

For businesses looking to implement Fin Copper Tubes in their refrigeration or air conditioning systems, selecting a reliable Fin Copper Tube Manufacturer and Supplier is crucial. Partnering with established manufacturers ensures that the products are of high quality, compliant with international standards, and durable enough to meet the demanding conditions of modern cooling systems.

Working with trusted Copper Tube Factory and suppliers also guarantees timely delivery, competitive pricing, and support services that can help businesses optimize their systems for energy efficiency and performance.

Product Category

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文