Copper Tube Industry's Value Reconstruction: From "Volume Expansion" to "Quality Breakthrough", How are Chinese Companies Breaking Through the Profit Margin Dilemma?

Subtitle:While the operating income of listed copper tube companies continues to grow, their core profits are declining. In the face of overcapacity and homogenization competition, leading companies are seeking breakthroughs through high-end transformation and going global.

Industry Dilemma: Revenue Growth and Profit Decline, Highlighting Structural Challenges

In 2024, China's copper tube industry exhibits a paradoxical phenomenon: overall supply exceeds demand, with the capacity utilization rate of small and medium-sized enterprises dropping below 60%, yet the industry's concentration is increasing. Data reveals that the combined copper tube production capacity of three listed companies—Hailiang Co., Ltd., Jintian Co., Ltd., and Jingyi Co., Ltd.—accounts for 37% of the national total . However, despite a year-on-year revenue growth of 8.5% for Jintian Co., Ltd. in the first half of 2024, its core net profit declined by 40.3% . This indicates that the industry's growth still relies on scale expansion, while the profitability of individual products continues to weaken.

The sharp decline in processing fees is a direct reflection of homogenized competition. The processing fee for inner grooved tubes has dropped from 9,000 yuan/ton to around 5,000 yuan/ton, a decrease of about 44% . Although the "old-for-new" policy and export growth have driven demand—household air conditioner copper tube consumption increased by 11.7% year-on-year in the first half of 2024 —this demand growth is primarily concentrated in the mid-to-low end, failing to alleviate the industry's price war.

Table: Performance Comparison of Listed Copper Tube Companies (First Half of 2024)

|

Company |

Operating Revenue (Billion CNY) |

Year-on-Year Revenue Change |

Core Net Profit (Million CNY) |

Year-on-Year Profit Change |

|

Jintian Co., Ltd. |

57.81 |

+8.5% |

12 |

-40.3% |

|

Hailiang Co., Ltd. |

44.03 |

+0.6% |

62 |

-27.5% |

|

Jingyi Co., Ltd. |

1.72 |

+26.0% |

1.36 |

-34.5% |

High-end Breakthrough: From "Volume Expansion" to "High-value Transformation"

Faced with profit compression, leading companies are shifting towards high-end markets. Hailiang Co., Ltd., by acquiring Germany's KME specialty copper tube business, obtained European technical standard certifications and successfully entered Airbus's supply chain . Jintian Co., Ltd. is developing high-value-added products like copper-graphene composite materials, achieving an ultra-high conductivity of 111% IACS, breaking foreign monopolies in key areas.

The high-end market demonstrates completely different characteristics. The profit margin for precision copper tubes can reach 25%-30%, far exceeding the 3%-5% for ordinary copper tubes . This is primarily because high-end products like ultra-thin-walled copper tubes (wall thickness ≤0.25mm) and corrosion-resistant copper alloys have technical barriers, with lead times extending to 12-18 months, creating a seller's market .

Going Global: Resolving Domestic Overcapacity Through Global Layout

To cope with domestic overcapacity, Chinese copper tube companies are accelerating their global expansion. Hailiang Co., Ltd. and Jinlong Co., Ltd. have established production bases in Vietnam and Thailand, with the total output of Chinese copper companies' overseas copper tube bases increasing by 46.3% year-on-year in 2024 . This strategy not only avoids trade barriers but also leverages local cost advantages—for example, the production cost at Wieland's new plant in Poland is 18% lower than in Germany .

The European market has become a key area for breaking into high-end sectors. By adopting a localization model of "dispatching only one Chinese executive," Chinese copper tube companies have significantly enhanced their brand premium capability in the European market . In 2024, China's copper tube export volume reached 308,500 tons, a year-on-year increase of 14.6%, setting a new historical record .

Technological Innovation: R&D Investment Reshapes Core Competitiveness

Against the backdrop of overall industry profit decline, companies that maintain high R&D investment demonstrate strong risk resistance. Botong New Material's independently developed "ultra-low oxygen split horizontal continuous casting method" reduces production costs to one-eighth of the original while increasing output by 30 times . This technological breakthrough enables Chinese companies to compete with international giants in the high-end market.

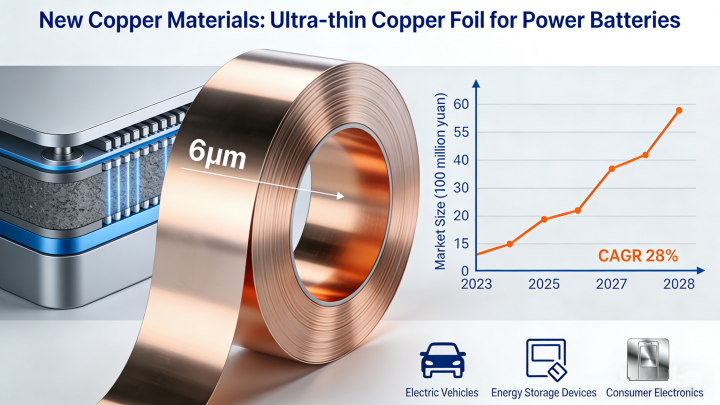

The new energy sector has become a new growth driver. The rapid development of new energy vehicles and lithium batteries has spurred demand for high-end copper materials. In 2024, the output of new energy vehicles in China increased by 37.4% year-on-year, directly driving demand for related copper materials . Companies like Botong New Material have successfully developed 4.5-micron high-strength lithium battery copper foil, entering the supply chain of leading batter.

Figure: Breakthroughs in new copper materials, such as ultra-thin copper foil for power batteries, are opening up new growth markets

Future Trends: High-end and Globalization Become Inevitable Paths

Looking ahead, the copper tube industry will present a "two-tier" development pattern. On one hand, the homogenization competition in the mid-to-low end market will intensify, processing fees may continue to decline, and companies without technological advantages will face elimination. On the other hand, the high-end market will maintain rapid growth, with the application of new materials such as nanocoated antibacterial copper tubes and self-healing copper tubes further expanding the market space .

Policy guidance will also drive industry reshuffle. The "Copper Industry High-Quality Development Implementation Plan (2025-2027)" issued by the Ministry of Industry and Information Technology explicitly controls new production capacity and lists recycled copper utilization as a strategic direction . This means that companies with green production technologies will gain more development opportunities.

Value Reconstruction is the Only Way for the Copper Tube Industry to Break Through

The copper tube industry is at a critical juncture of transformation. Companies relying solely on price competition will find it difficult to survive in the red ocean of homogenization. In the future, only by achieving breakthroughs in technology research and development, product innovation, and global layout can companies gain a place in the fiercely competitive market. The development experience of leading companies fully demonstrates that high-end and globalization are the only paths for the copper tube industry to achieve value reconstruction.

Product Category

Content

- Industry Dilemma: Revenue Growth and Profit Decline, Highlighting Structural Challenges

- High-end Breakthrough: From "Volume Expansion" to "High-value Transformation"

- Going Global: Resolving Domestic Overcapacity Through Global Layout

- Technological Innovation: R&D Investment Reshapes Core Competitiveness

- Future Trends: High-end and Globalization Become Inevitable Paths

- Value Reconstruction is the Only Way for the Copper Tube Industry to Break Through

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文