Copper Tube Industry Enters the "Intelligent Manufacturing" Era: How Digitalization and New Materials are Reshaping a Century-Old Traditional Industry?

Smart Factories: Disruptive Shift from "Experience-Based Production" to "Data-Driven"

In 2025, the intelligent transformation of China's copper tube industry is accelerating. Jiangxi Jinlong Copper Tube Group built the industry's first Excellence-level smart factory, achieving data collection from 110 connected devices, which improved order response efficiency by 40% and reduced energy consumption per unit product below the national first-level standard. At Guangdong Longfeng Precision Copper Tube's 5G digital twin factory, each production line is equipped with micro 5G base stations, reducing equipment data latency to milliseconds and enabling fully digital management from raw material feeding to finished product packaging.

The application of intelligent production scheduling systems is particularly prominent. Traditional copper tube enterprises relied on experienced masters for scheduling, requiring adjustments every 2-3 days; whereas smart factories use AI algorithms to generate optimal production plans in real-time based on order priority, equipment status, and delivery dates, reducing the adjustment cycle to 2 hours. This transformation brings significant benefits: Jiangxi Yuntai Copper improved resource utilization by 15% and saves over CNY 400,000 annually through MES system integration.

Table: Key Indicator Comparison of Intelligent Transformation in China's Copper Tube Industry (2025)

|

Transformation Dimension |

Traditional Production Mode |

Intelligent Production Mode |

Efficiency Improvement |

|

Production Plan Adjustment |

Every 2-3 days |

Every 2 hours |

36x faster |

|

Quality Inspection |

Manual sampling (3% coverage) |

AI visual full inspection (100% coverage) |

Defect miss rate reduced by 90% |

|

Energy Management |

Monthly report analysis |

Real-time monitoring and early warning |

Unit energy consumption reduced by 30% |

|

Equipment Maintenance |

Repair after failure |

Predictive maintenance |

Downtime reduced by 70% |

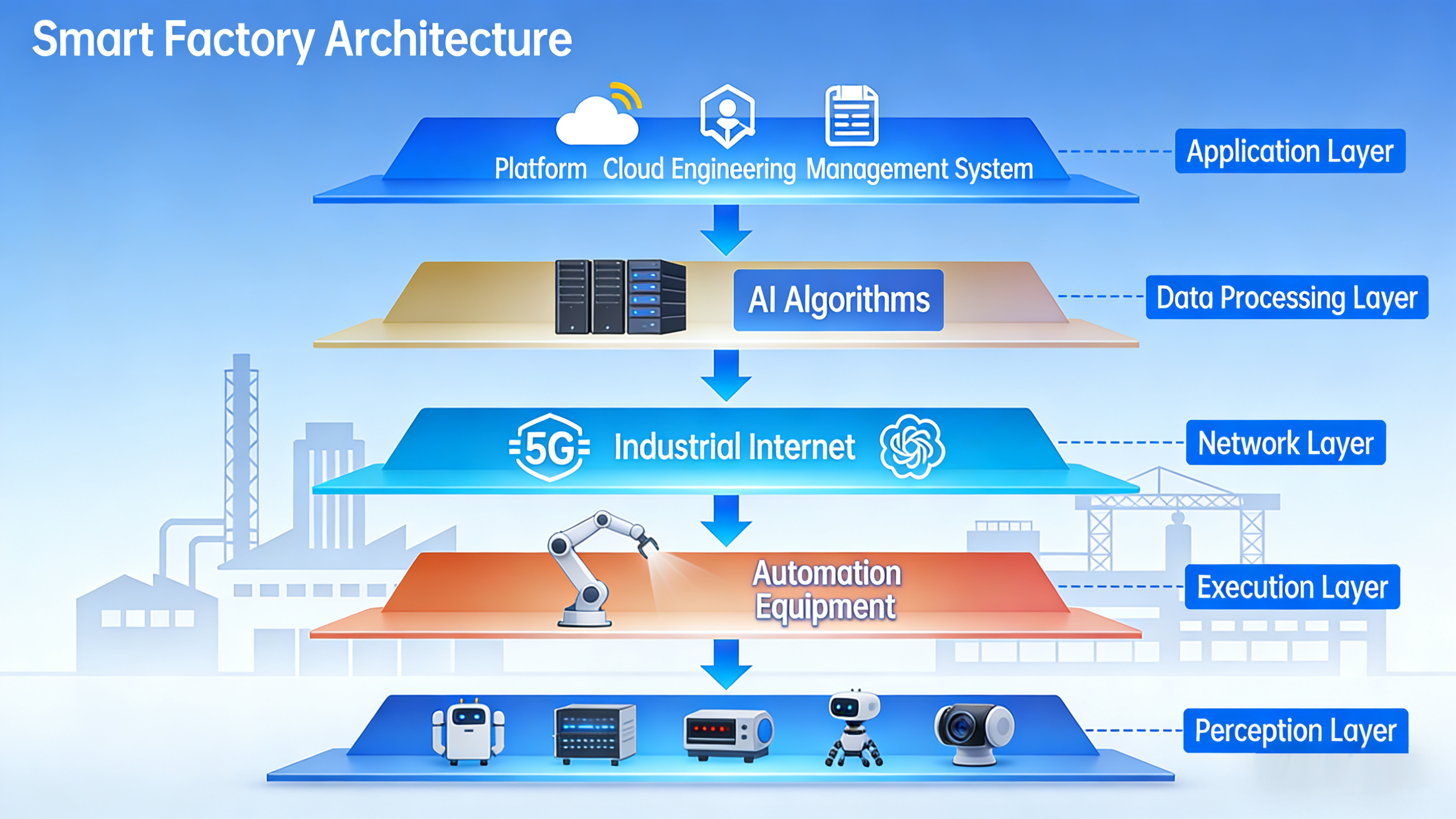

Figure: Smart factory architecture typically includes perception, network, data processing, execution, and application layers, enabling data flow from sensors to cloud platforms.

Material Revolution: Leap from "Basic Copper Tubes" to "Functional Customization"

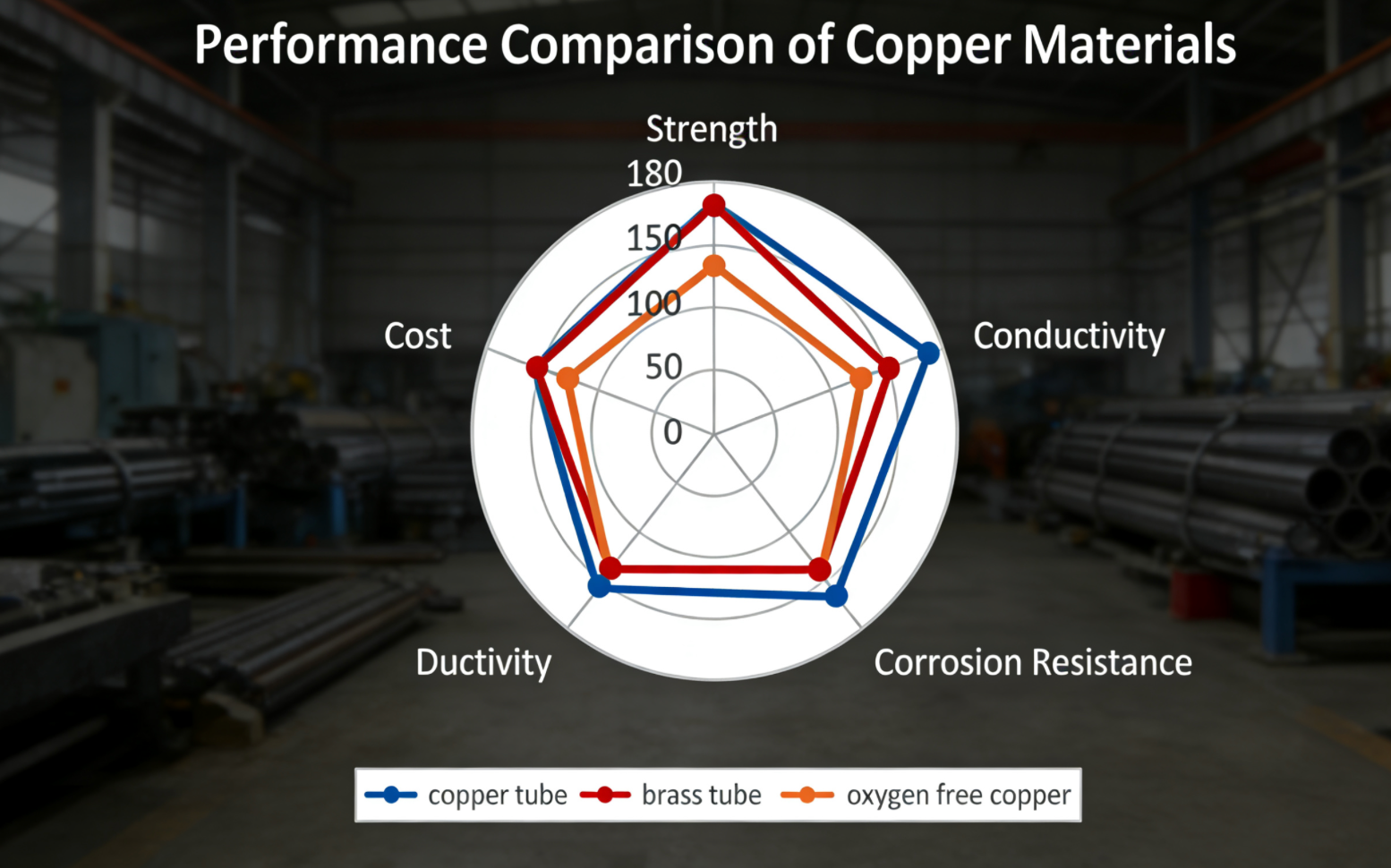

Innovation in copper tube materials is continuously expanding application boundaries. Jiangxi Nailuo Copper Industry developed high-purity, ultra-low oxygen precision copper tubes with oxygen content controlled below 5ppm, increasing processing fees to six times that of ordinary products and successfully breaking foreign technological monopolies. This material breakthrough allows copper tubes to enter high-end fields like semiconductor sputtering targets and power battery liquid cooling systems.

Thinner, stronger copper-based new materials are becoming the focus of competition. Gansu Hailiang New Energy Material Research Institute produces 3.5-micron ultra-thin lithium battery copper foil, as thin as 1/10 of a human hair, with a tensile strength exceeding 700 MPa. This ultra-thin foil can increase battery energy density by 1%-2%, directly boosting new energy vehicle range. Jiangxi Kangcheng Tedao New Material's ultra-fine copper alloy conductor wires, with diameters one-sixth of a hair, command processing fees 100 times higher than ordinary copper tubes.

Functional customization is key to differentiated competition. For different application scenarios, companies developed antibacterial, self-healing, and high thermal conductivity copper tubes. In the Yingtan High-tech Zone, companies can produce customized tubes with wall thickness tolerance controlled within ±0.003mm, meeting extreme demands in medical and aerospace fields.

Technological Breakthroughs: Path from "Introduction and Absorption" to "Independent Innovation"

The technological advancement path of China's copper tube industry has fundamentally changed. Tai Heavy Group independently developed a 6000 US ton forward double-acting copper extrusion machine, breaking foreign monopolies in large copper extrusion equipment and enabling China to produce large-diameter copper tubes for nuclear power and marine engineering independently. This equipment uses digital twin technology for virtual commissioning, achieving millimeter-level installation accuracy.

Industry-university-research collaboration proved effective. Jiangxi Nailuo Copper and Jiangxi University of Science and Technology's "ultra-low oxygen separate horizontal continuous casting method" replaced expensive foreign "vacuum methods," reducing production costs to one-eighth and increasing output 30-fold. Through this "enterprise poses problems, universities solve them" model, experts from Nanchang University joined enterprises as "technology vice presidents" to tackle industry challenges.

Intelligent R&D tools accelerate technological iteration. Hailiang uses digital twin technology to create virtual material R&D platforms, cutting new material development from 18 months to 6 months. AI-assisted design systems simulate performance of different alloy ratios, tripling R&D success rates.

Green Manufacturing: Sustainable Development from "Energy Consumption Control" to "Zero-Carbon Factories"

Environmental standards are reshaping the industry landscape. The EU's Carbon Border Adjustment Mechanism (CBAM) imposes additional carbon costs on traditionally produced copper tubes, while low-carbon tubes with over 80% recycled copper receive tariff exemptions. This pressures Chinese companies to accelerate green transformation.

Leading companies built full lifecycle carbon management systems. Hailiang's fifth-generation intelligent production line increased annual capacity per line by 80%, reduced unit product energy consumption by 30%, uses 150,000 tons of recycled copper annually, and cuts CO2 emissions by 156,000 tons. Jinlong Copper Tube Group's energy management platform enables real-time monitoring and optimization of electricity, gas, and water consumption, saving 18,500 tons of standard coal annually.

Zero-carbon factories set new benchmarks. A Jiangsu copper tube enterprise built the industry's first integrated photovoltaic smart factory, with rooftop solar panels meeting 60% of production needs and exporting surplus power for "negative carbon" production. This model is promoted nationwide, with the industry's recycled material usage rate expected to rise from 35% to over 50% by 2028

Future Trends: How Smart Copper Tubes Empower the Era of Internet of Things

With 5G and IoT adoption, smart copper tubes are becoming key components in smart cities. Embedded sensors monitor flow, temperature, and pressure in real-time, enabling early leak warnings. In smart buildings, these tubes interconnect with building management systems to automatically adjust heating/cooling, optimizing energy use.

The Tubes-as-a-Service model emerges. Leading companies now offer integrated "copper tubes + monitoring + maintenance" services instead of just products. Customers pay based on usage effects, and manufacturers optimize pipeline performance using real-time data, creating win-win situations. This model suits large commercial complexes and data centers, potentially capturing 30% of the high-end market by 2030.

Personalized customization meets consumer demand. Using 3D printing and flexible manufacturing, companies accept small-batch, varied orders for DIY enthusiasts and professional clients. This means copper tubes could soon be sold directly to end-users via e-commerce platforms like regular goods.

New Quality Productive Forces Reshape the Copper Tube Industry's Value Logic

The copper tube industry's transformation is essentially the remodeling of traditional manufacturing by new quality productive forces. Intelligentization is no longer optional but essential for survival; material innovation is no longer confined to labs but is a competitive weapon; green transformation is not just policy-driven but a prerequisite for development.

Over the next five years, the pattern of "the strong getting stronger" will intensify: leading companies with technical advantages and scale effects will expand their lead through continuous R&D investment; while OEMs lacking innovation capability may be forced out. For Chinese companies, seizing the twin engines of intelligentization and new materials is crucial for dominating the global copper tube industry.

Product Category

Content

- Smart Factories: Disruptive Shift from "Experience-Based Production" to "Data-Driven"

- Material Revolution: Leap from "Basic Copper Tubes" to "Functional Customization"

- Technological Breakthroughs: Path from "Introduction and Absorption" to "Independent Innovation"

- Green Manufacturing: Sustainable Development from "Energy Consumption Control" to "Zero-Carbon Factories"

- Future Trends: How Smart Copper Tubes Empower the Era of Internet of Things

- New Quality Productive Forces Reshape the Copper Tube Industry's Value Logic

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文