A Reliable Partner of the Copper Tube Industry

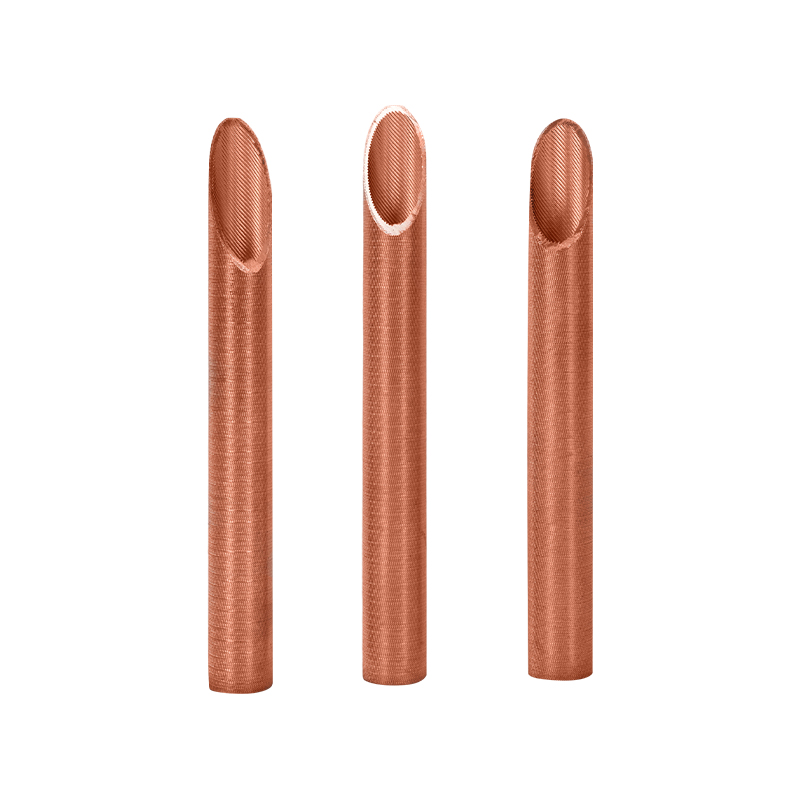

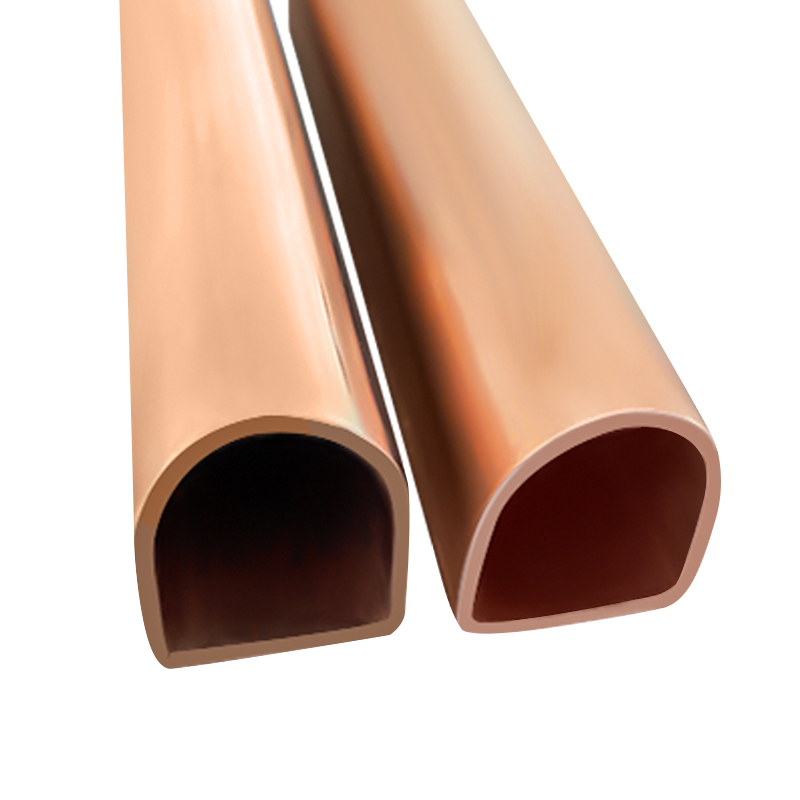

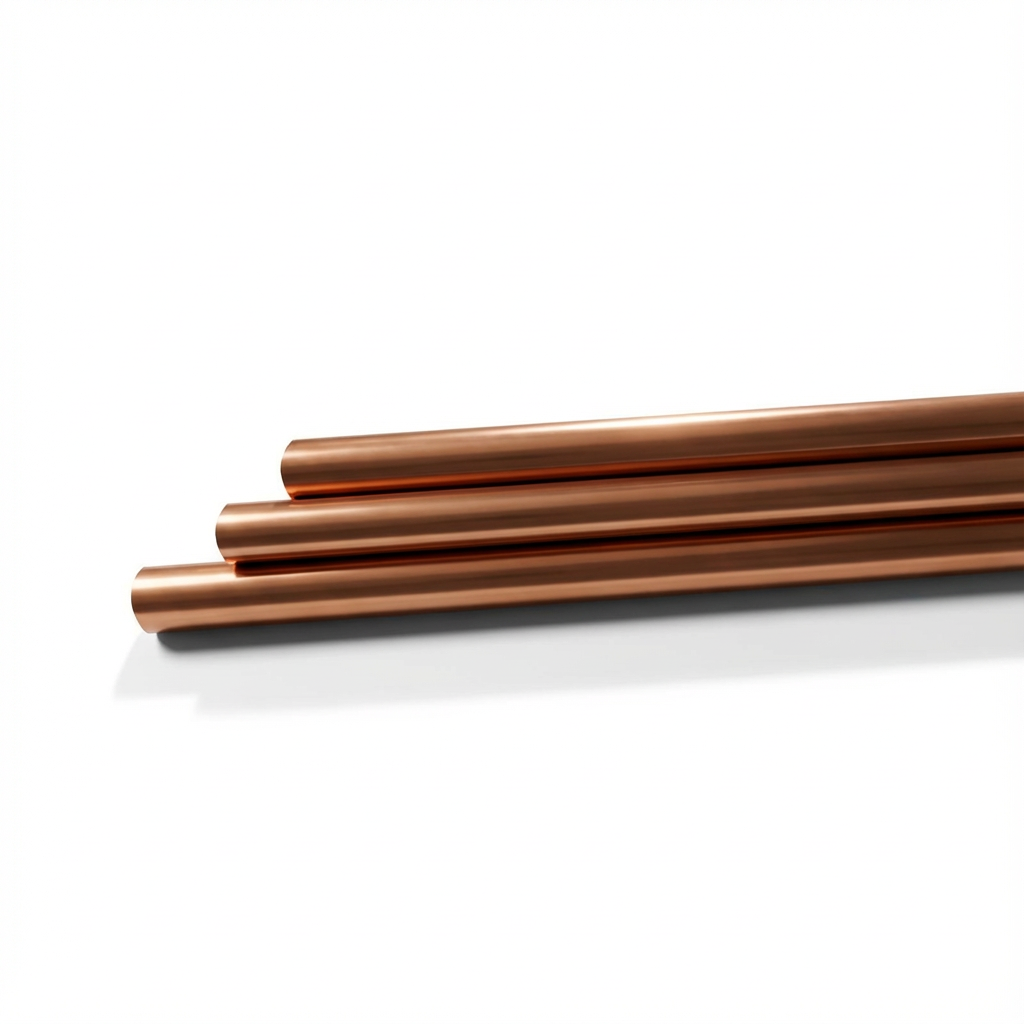

Zhejiang Jingliang Copper-Tube Products Co., Ltd is China Metric Size Copper Tubing and Metric Size Copper Tubing Factory, which established in 1994, has been deeply involved in the copper tube industry for over three decades. The company primarily produce various specifications of products such as copper tubes, brass tubes, copper square tubes, fin copper tubes, copper capillary tubes, condenser copper tubes, copper evaporator tubes, and conductive rods, which are of quality and have earned the trust and acclaim of customers both domestically and internationally.

Wide Applications:

These products are widely used in various fields including air conditioning, refrigeration, heat exchange, sanitary ware, automotive, machinery, electric furnaces, and chemical industries.

Convenient Transportation:

Strategically located in Tangpu Town, renowned as the “home of copper tubes” in East China. Our company enjoys a prime location, adjacent to the Shangsan Expressway and National Highway 104, and is conveniently situated just over 70 kilometers from Hangzhou and Ningbo, ensuring easy accessibility and a business position.

Strong Financial Resources:

With its strong financial resources and advanced copper tube processing technology, our company holds an advantageous position in market share, brand value, technological content, and product quality, becoming a preferred supplier for many listed groups.

Large Scale Production:

The company occupies an area of over 20,000 square meters, with a construction area of 12,800 square meters. In 2022, our annual production exceeded 7,500 tons, with a value output of up to 450 million yuan, demonstrating our strong production capacity and market competitiveness.

Comprehensive Industry Chain:

Jingliang has now developed into a complete industrial chain integrating smelting, extrusion, drawing, precision rolling, and annealing. It has been awarded multiple honors, including "Top Ten Copper Tube Enterprises" and "Leading Taxpayer in the Copper Tube Industry".

Smart Manufacturing:

Jingliang Copper-Tube Products will better integrate the concept of factory construction into its corporate development strategy, insist on refining technology and polishing products more finely, and the future of "intelligent manufacturing".

Genuine Cooperation:

Zhejiang Jingliang Copper-Tube Products Co.,Ltd warmly welcomes friends from all walks of life to visit and offer guidance. We look forward to joining hands with you to create a brilliant future together.

English

English Español

Español 中文

中文