Why Copper Capillary Tubes Are Crucial for Microfluidic Devices

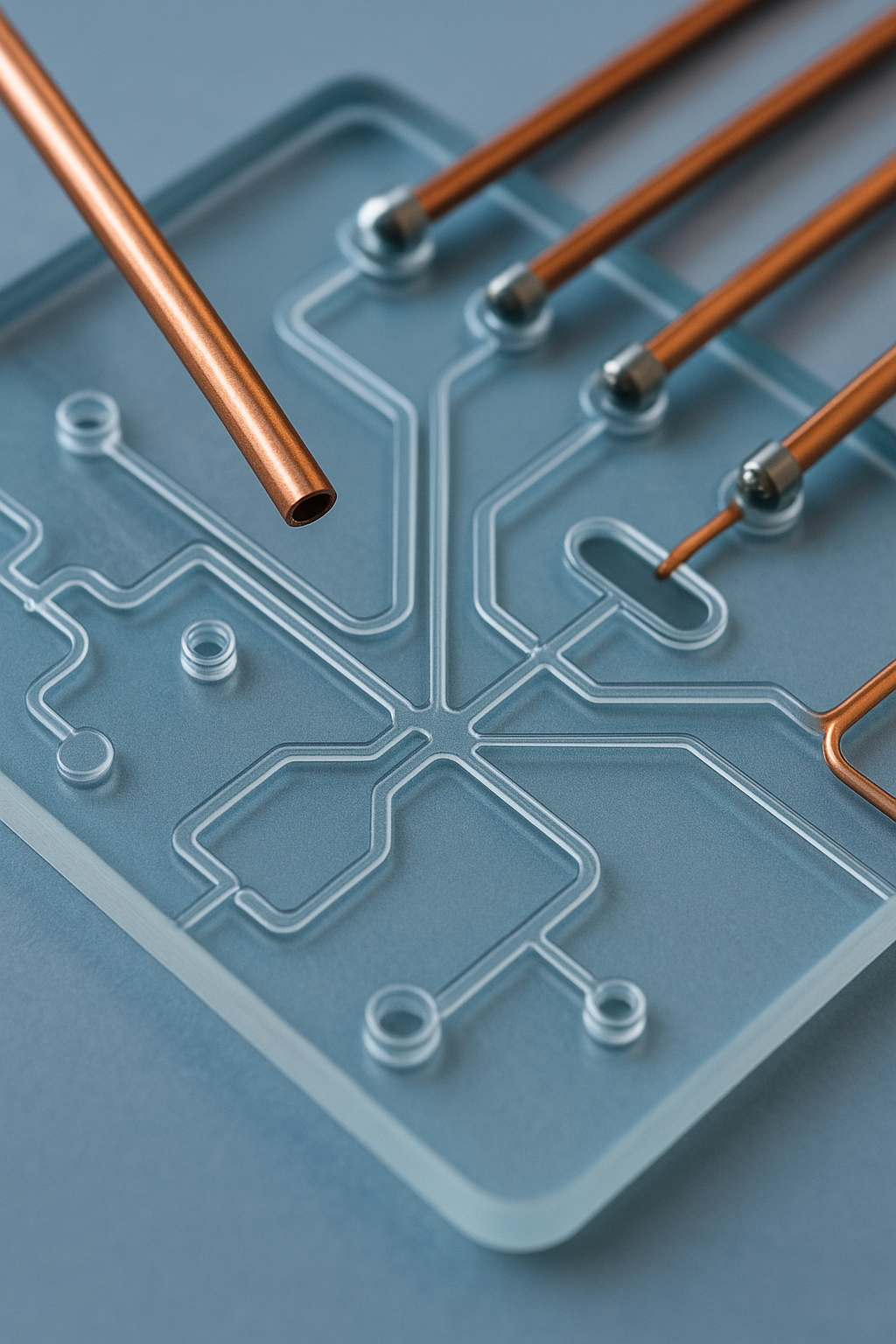

In the rapidly advancing field of microfluidics, small-scale fluid manipulation is at the core of many groundbreaking technologies. Microfluidic devices, which control the movement of liquids in channels measuring micrometers in diameter, have found applications in fields such as healthcare, diagnostics, and environmental monitoring. Among the key components driving this revolution are copper capillary tubes. These tubes, manufactured in specialized copper tube factories by copper tube manufacturers, offer a blend of thermal conductivity, durability, and biocompatibility that make them indispensable in microfluidic systems.

The Rise of Microfluidic Devices

Microfluidics is an emerging technology that deals with the control and manipulation of fluids at a very small scale. Devices built using microfluidic principles are crucial for applications ranging from point-of-care diagnostics and genetic testing to environmental sensing and pharmaceutical research. These systems, often referred to as “lab-on-a-chip” devices, allow for the analysis of chemical reactions, mixing of fluids, and even the simulation of biological processes in a compact, automated system.

The precise manipulation of fluids at such a small scale requires specialized components that can withstand extreme conditions, such as varying temperatures, high pressures, and exposure to chemical reagents. Copper capillary tubes, produced by copper tube manufacturers, play a vital role in ensuring the accuracy and efficiency of these devices. Their unique properties make them an essential material for regulating fluid flow, controlling temperature, and ensuring device longevity.

The Key Properties of Copper Capillary Tubes

Copper capillary tubes, which are thin, hollow copper tubes, offer several advantages in microfluidic applications. These advantages stem from the intrinsic properties of copper, a metal that is well-known for its versatility and performance in various industries. Here are the key reasons why copper capillary tubes stand out in microfluidic technology:

High Thermal Conductivity

Copper is renowned for its exceptional thermal conductivity, one of the highest among metals. This makes copper capillary tubes ideal for microfluidic applications that require precise temperature regulation. Many microfluidic devices, such as those used in PCR (Polymerase Chain Reaction) or drug delivery systems, require a consistent thermal environment to ensure the accuracy of reactions or the stability of biological samples.

Copper capillary tubes can quickly absorb and disperse heat, allowing these devices to maintain the necessary temperatures for complex chemical and biological processes. For instance, in microreactors used for chemical synthesis, copper tubes can help maintain the desired reaction temperature, ensuring that the process proceeds efficiently without overheating the fluids or samples.

Strength and Durability

Microfluidic systems often need to handle high-pressure conditions as fluids are pumped through narrow channels at precise flow rates. Copper tubes, including copper capillary tubes, are known for their strength and durability, which allows them to withstand these conditions without compromising the integrity of the system.

The manufacturing process at a copper tube factory involves creating tubes that are both lightweight and capable of withstanding substantial mechanical stress. The high strength of copper capillary tubes means they can endure the physical demands of microfluidic systems, including resistance to the pressure fluctuations that can occur in medical and industrial applications.

Additionally, copper's corrosion resistance ensures that the tubes can perform reliably over extended periods, even when exposed to harsh chemicals, biological agents, or corrosive fluids.

Biocompatibility and Antimicrobial Properties

When it comes to microfluidic devices used in healthcare and life sciences, biocompatibility is a critical consideration. Materials used in such devices must not cause unwanted reactions or contamination that could affect the integrity of biological samples. Copper is naturally biocompatible, making it an excellent material for medical applications.

Moreover, copper has intrinsic antimicrobial properties that inhibit the growth of bacteria and fungi. This feature is particularly valuable in medical diagnostics, where contamination could lead to inaccurate results. By utilizing copper capillary tubes, microfluidic devices can reduce the risk of microbial growth, ensuring the cleanliness and accuracy of the device’s functions.

Precision Fluid Control

Capillary action—the ability of a liquid to flow through a narrow tube without external forces—is a crucial principle in microfluidics. Copper capillary tubes, due to their precise inner diameters and smooth surfaces, are ideal for creating controlled fluidic environments. Copper tubes are manufactured with exceptional accuracy in copper tube factories, ensuring that the inner diameter of the capillary tubes meets the tight specifications required for microfluidic applications.

The ability of copper capillary tubes to provide precise fluid flow is particularly important in laboratory settings, where even minor fluctuations in fluid delivery can significantly impact the outcome of experiments. This is especially crucial in applications like genetic sequencing, where the controlled mixing of reagents is necessary for accurate test results.

Cost-Effectiveness and Availability

Another important factor that contributes to the widespread use of copper in microfluidic systems is the cost-effectiveness of copper tubes. Copper is widely available, and the processes used to manufacture copper tubes—such as extrusion and drawing—are relatively inexpensive compared to the production of more exotic materials. As a result, copper capillary tubes offer a balance between high performance and affordability.

In industries where cost is a significant consideration, such as healthcare and diagnostics, copper capillary tubes provide an ideal solution. By sourcing copper tubes from established copper tube manufacturers, companies can produce microfluidic devices at scale without sacrificing quality or performance.

Electrical Conductivity for Hybrid Applications

Microfluidic devices increasingly incorporate hybrid functionalities, where both fluid manipulation and electrical control are necessary. Copper is an excellent conductor of electricity, which makes copper tubes highly suitable for applications that require both fluid transport and electrical conductivity.

For example, in electrokinetic microfluidics, which uses electric fields to drive the movement of fluids, copper capillary tubes can be integrated with electrodes to control fluid flow in a precise and controlled manner. This capability is especially important in applications like DNA analysis or electrochemical sensing, where both electrical and fluidic parameters must be controlled simultaneously.

|

Property |

Copper Capillary Tubes |

Stainless Steel Tubes |

Other Materials (e.g., Plastics) |

|

Thermal Conductivity |

Extremely high, fast heat dissipation |

Low, slower heat transfer |

Very low, poor thermal conduction |

|

Mechanical Strength |

High strength and pressure resistance |

Strong, but not as high as copper |

Weak, prone to deformation or breakage |

|

Biocompatibility |

Excellent, with antimicrobial properties |

Moderate, can cause allergic reactions |

Depends on plastic type, generally lower |

|

Corrosion Resistance |

Good, especially in moist environments |

Good, but may be susceptible to chemical corrosion |

Susceptible to chemical corrosion |

|

Fluid Control Precision |

Very high, ideal for microfluidic control |

Medium, less precise |

Low, difficult to maintain accurate flow |

|

Electrical Conductivity |

High, suitable for electrical applications |

Moderate, not suitable for electrical applications |

Low, unsuitable for electrical use |

|

Cost |

Relatively low, easy to process |

Higher, complex manufacturing process |

Low, but performance is poor |

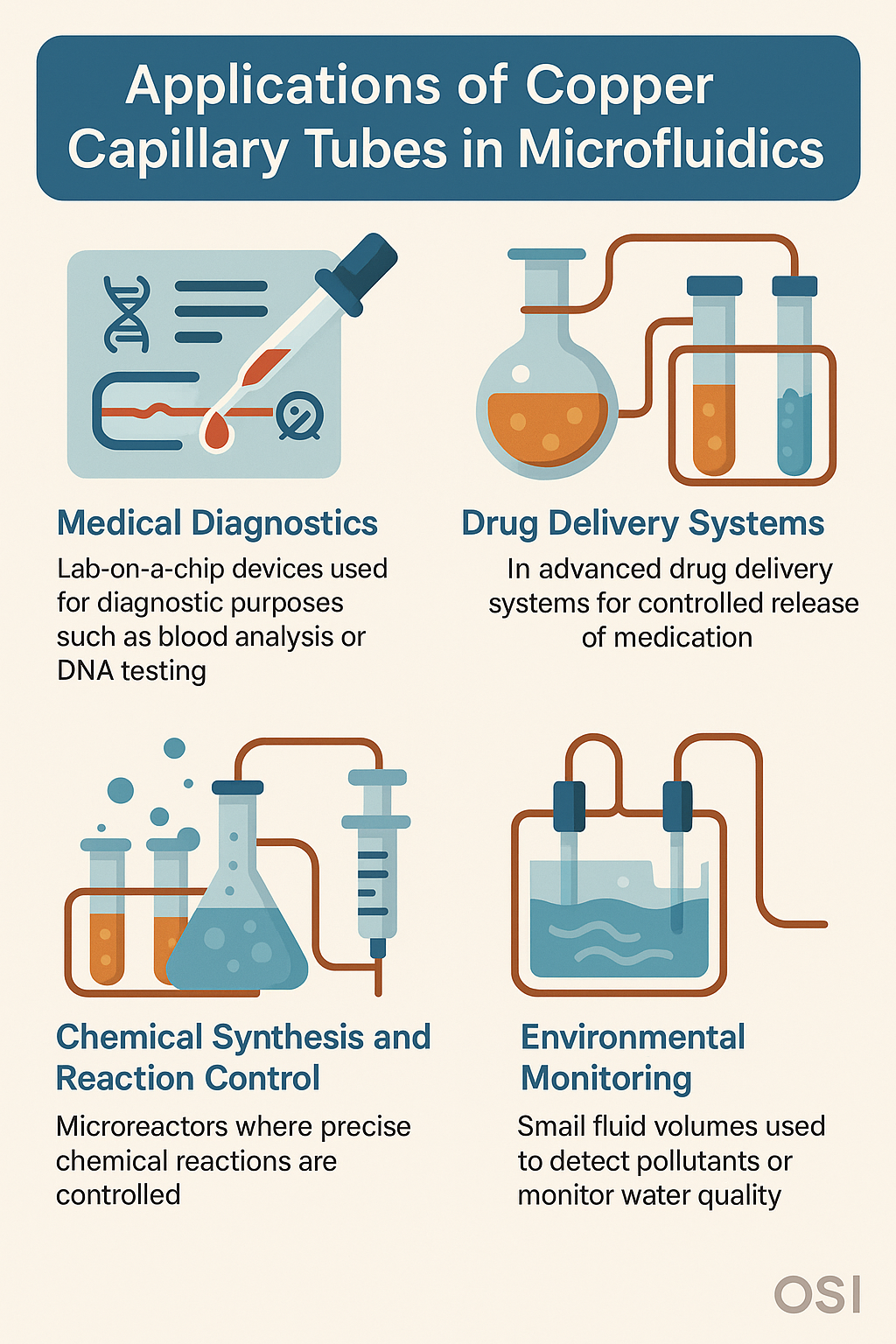

Applications of Copper Capillary Tubes in Microfluidics

The versatility of copper capillary tubes allows them to be used in a variety of microfluidic applications. Some of the most prominent fields where these tubes are employed include:

Medical Diagnostics

Lab-on-a-chip devices, used for diagnostic purposes such as blood analysis or DNA testing, require precision fluid control. Copper capillary tubes are ideal for these devices, as they help deliver fluids to reaction zones while maintaining temperature control. The antimicrobial properties of copper also ensure that the system remains sterile, preventing contamination that could affect the accuracy of the results.

Drug Delivery Systems

In advanced drug delivery systems, especially those that involve controlled release of medication or precise targeting of specific tissues, copper capillary tubes are used to regulate fluid flow and maintain steady delivery rates. The ability to finely control fluid movement and temperature is vital for ensuring the effectiveness and safety of the drug.

Chemical Synthesis and Reaction Control

Copper tubes are used in microreactors, where precise chemical reactions need to be controlled in miniaturized environments. Copper's thermal conductivity allows for the rapid adjustment of reaction temperatures, ensuring that the synthesis process occurs under the optimal conditions for maximum yield and efficiency.

Environmental Monitoring

In environmental monitoring applications, where small fluid volumes are used to detect pollutants or monitor water quality, copper capillary tubes are employed for precise fluid handling. Copper’s resistance to corrosion makes it a durable option for use in challenging outdoor environments.

The Future of Copper Capillary Tubes in Microfluidics

As microfluidic technologies continue to evolve, the role of copper capillary tubes is expected to grow even further. Advances in material science may lead to enhanced coatings or alloy compositions that improve the properties of copper, such as its resistance to specific chemicals or its biocompatibility. Copper tube manufacturers are continually innovating to meet the evolving demands of industries that rely on these devices.

With increasing demand for microfluidic solutions in healthcare, diagnostics, and industrial applications, copper capillary tubes will remain at the forefront of this technological revolution. Their unique combination of performance, cost-effectiveness, and versatility makes them an indispensable part of the future of microfluidic devices.

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文