From Plumber's Staple to Tech Core: Is This the Great Transformation of the Copper Tube?

The story is no longer about selling copper tubes; it's about selling thermal efficiency, energy sustainability, and digital reliability. The copper tube industry is quietly engineering a revolution from within, redefining its role in the technologies of tomorrow.

The Silent Reinvention

For centuries, the copper tube has been a fundamental commodity, valued for its simplicity and consistency. Historically, its worth was measured by length and weight. Today, this traditional product is undergoing a remarkable transformation. The most innovative copper tube manufacturers are no longer merely metal fabricators—they have evolved into essential partners for the world's leading industries. This evolution goes beyond fluctuations in the market; it represents a significant shift from being a copper tube supplier to becoming a technology enabler in sectors such as construction, HVAC, and electronics. As the demand for precision copper tubing continues to grow, copper tube factories are at the forefront of this exciting change, developing advanced solutions that drive industry progress.

The Catalyst – Demands from the Frontiers of Technology

The transformation of the copper tube industry is being driven by unprecedented performance requirements from three technological frontiers.

The Electric Vehicle Mandate: Beyond Cooling, Towards Range Optimization

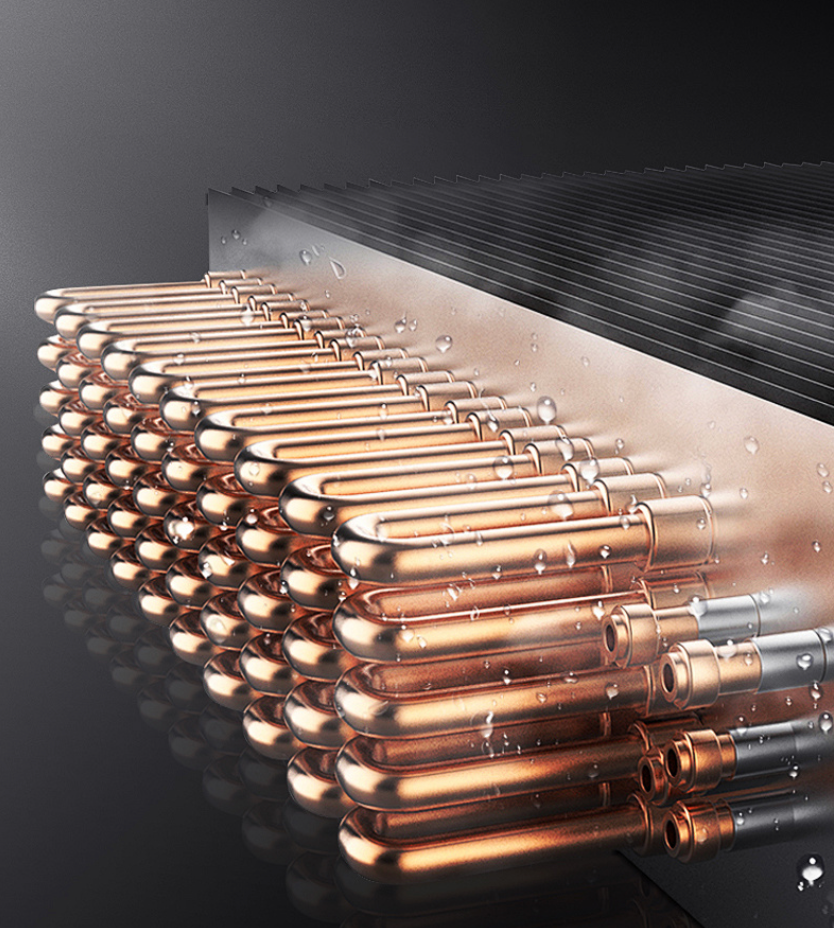

For electric vehicle (EV) manufacturers, the copper tube inside a battery thermal management system plays a crucial role beyond simple cooling. Its thermal conductivity directly affects charging speed, battery lifespan, and the vehicle's overall range. This has led to innovations in copper tube design, including the adoption of micro-channel tubes that maximize surface area within minimal space. To meet these demands, the copper tube manufacturer must now master precision forming techniques and work with advanced alloys to prevent corrosion caused by new coolant types. The copper tube is no longer just a component—it has become an integral thermal management solution.

The Data Center Imperative: Heat as the Enemy of Progress

As processor power densities increase exponentially, traditional air cooling methods are no longer sufficient. The shift toward liquid cooling has placed a specialized copper tube at the heart of data center infrastructure. These tubes must maintain absolute integrity, with leak-proof joints and custom shapes designed to fit densely packed server racks. Here, the value of the copper tube extends beyond the material itself, to the engineering precision and design collaboration offered by the copper tube factory. This collaboration enables the creation of highly specialized solutions that meet the unique needs of high-performance computing.

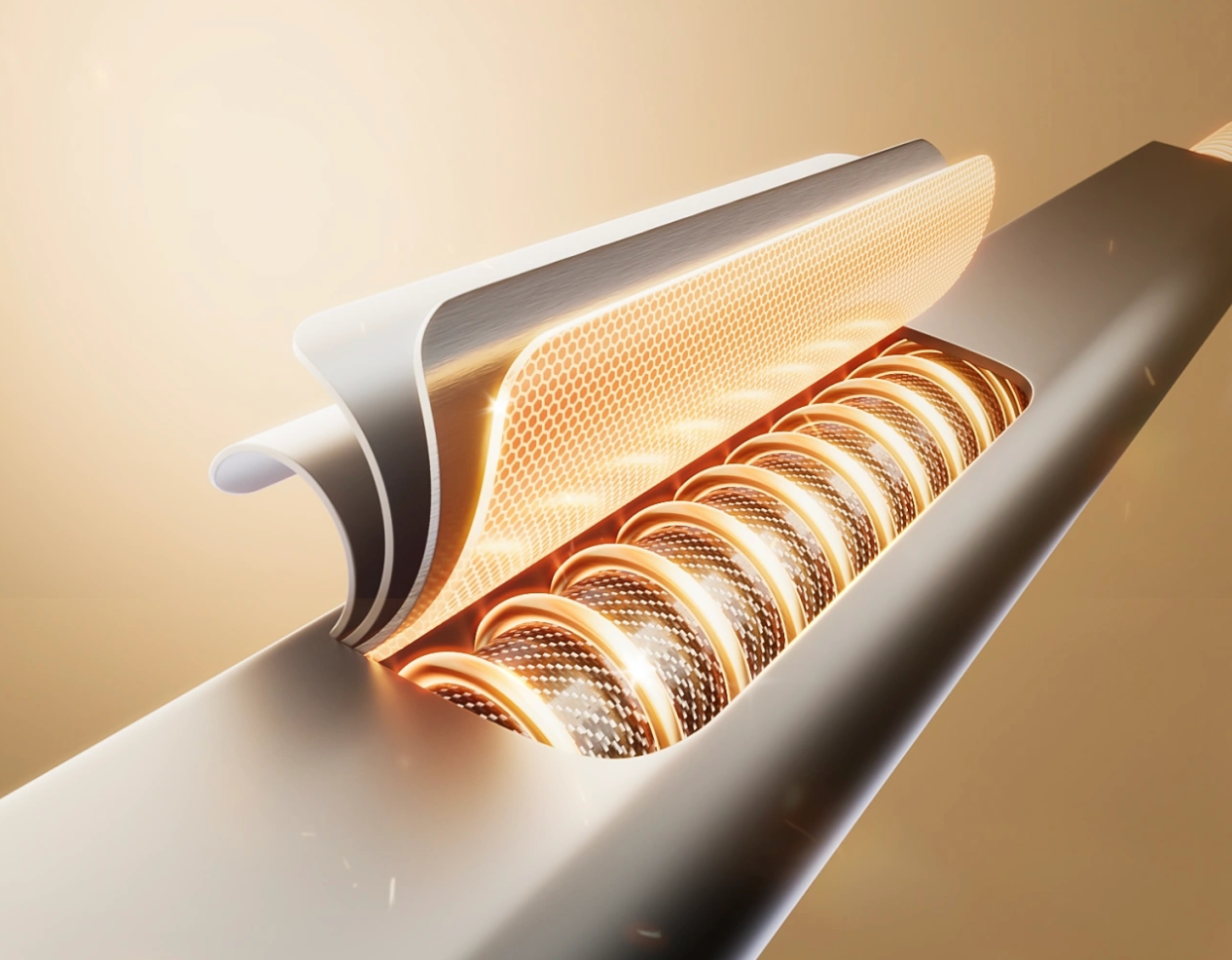

The Energy Transition: Reliability for Decades

In large-scale energy systems, such as solar thermal plants and energy storage systems, copper tubes must deliver reliable performance for 25+ years under extreme environmental conditions. Failure is not an option. This requires a copper tube manufacturer to provide not only a high-quality product but also a guarantee of performance, supported by rigorous testing and certification. The business model has shifted from simple one-time product sales to long-term partnerships based on trust and proven reliability. In the energy sector, a dependable copper tube factory is now seen as a key collaborator, providing lasting solutions that ensure the sustainability of these critical systems.

The Internal Revolution – How Copper Tube Factories are Transforming

To meet the escalating demands of industries like electric vehicles, data centers, and energy systems, the internal workings of a copper tube factory are undergoing a quiet yet profound revolution. These changes are not just incremental improvements; they are reshaping the entire approach to manufacturing copper tubes. Here’s how the transformation is taking place:

|

Aspect of Manufacturing |

Traditional Copper Tube Factory |

The Modern, Tech-Enabled Copper Tube Factory |

|

Core Focus |

Volume, Cost per Meter |

Precision, Performance, Customization |

|

R&D Spending |

Low; focused on process efficiency |

High; focused on material science and product innovation |

|

Production Lines |

High-volume, standardized batches |

Flexible, agile lines for small-batch, high-mix orders |

|

Quality Control |

Dimensional checks, pressure tests |

Advanced non-destructive testing, AI-powered defect detection |

|

Key Personnel |

Production engineers, machine operators |

Metallurgists, application engineers, data scientists |

|

Customer Interaction |

Through distributors, price-driven |

Direct collaboration with OEM R&D teams, solution-driven |

The New Business Paradigm – Selling Solutions, Not Just Copper Tubes

The transformation in the copper tube industry is reshaping business models at a fundamental level. Leading copper tube manufacturers are no longer competing purely on price—they’re driving value and innovation. This shift is giving rise to new sales strategies, pricing structures, and business practices that emphasize long-term partnerships and customized solutions.

The Rise of the Application Engineer

Gone are the days when salespeople simply quoted a price per meter of copper tube. Today, copper tube manufacturers deploy application engineers who collaborate directly with customers, often working inside customer labs to co-design thermal systems. These engineers focus on understanding the specific needs of industries such as electric vehicles (EVs), data centers, and energy storage, ensuring that the copper tube solutions are integrated seamlessly into complex systems. This customer-centric approach fosters deeper relationships and creates a more value-driven sales model.

Value-Based Pricing: Beyond the Meter

The pricing of copper tubes has evolved significantly. Instead of a simple equation of “Copper Price + Manufacturing Cost,” the cost now reflects the intellectual property (IP), customization, technical support, and the performance premium that the product enables. For instance, a copper tube used in an electric vehicle battery management system can command a price multiple times that of a standard plumbing tube, thanks to the advanced technology embedded within. This shift to value-based pricing underscores the growing importance of copper tube manufacturers offering not just a product, but an engineered solution that enhances overall system performance.

The Circular Economy as a Value Driver

Sustainability is no longer a secondary concern—it is central to the modern business model of copper tube factories. As the world moves toward a circular economy, copper tube manufacturers are increasingly adopting robust recycling programs, turning recycled copper into a competitive advantage. A copper tube factory that integrates sustainable practices can offer customers green credentials, ensuring a stable, eco-friendly material source. This sustainable approach not only benefits the environment but also enhances a company's reputation, positioning it as a responsible partner in industries where environmental responsibility is a key differentiator. The circular economy is no longer just a side project; it is a value driver that strengthens the manufacturer’s position in the market.

The Human Element: A Skillset Transformation

This industrial shift in the copper tube manufacturing sector requires a fundamental transformation in human capital. The industry now demands a new breed of skilled professionals: metallurgists to innovate and develop advanced copper alloys, data analysts to optimize production processes, and engineers who are experts in both fluid dynamics and the specialized needs of industries like electric vehicles (EVs) and data centers. As copper tube factories become more technology-driven, the role of workers on the factory floor is evolving from traditional machine operation to managing and monitoring sophisticated automated systems. This shift highlights the growing need for a highly trained workforce capable of navigating the complexities of modern copper tube production.

The Tube is Just the Beginning

The humble copper tube has evolved into a bellwether for how traditional industries can adapt and thrive in today’s high-tech era. Its transformation from a simple commodity to a customized, high-performance component is a powerful case study in industrial evolution. The companies that will succeed are those that understand they are no longer just in the copper tube business; they are now in the business of enabling the technologies of tomorrow. As industries like electric vehicles (EVs), data centers, and energy systems require increasingly sophisticated solutions, the role of copper tube manufacturers is being redefined. The great transformation is underway, and it is reshaping the industry’s place in the global value chain—one precision-engineered tube at a time.

Product Category

Content

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文