Are Pure Copper Tubes the Key to Ensuring Sterility and Reliability in Medical Applications?

In the medical industry, the safety and reliability of materials used in equipment and systems are paramount. One such material that has garnered attention in recent years is pure copper. Known for its exceptional properties, including antimicrobial effects, corrosion resistance, and high thermal and electrical conductivity, pure copper is increasingly being utilized in a variety of medical applications. Among these applications, pure copper tubes stand out as a critical component in many healthcare systems, from medical gas delivery systems to diagnostic equipment. The role of copper tube manufacturers and copper tube factories in providing these specialized products is becoming more critical as the demand for high-quality copper tubes in healthcare rises.

The Significance of Sterility in Medical Environments

Sterility is one of the most important factors when choosing materials for medical applications. In hospitals, clinics, and laboratories, the risk of contamination must be minimized to ensure the safety of both patients and medical professionals. Contaminated surfaces or materials can introduce harmful pathogens into sterile environments, leading to infections or compromising the performance of critical systems.

Pure copper, particularly in the form of copper tubes, plays a unique role in ensuring sterility. Copper is inherently antimicrobial, which means it can kill or inhibit the growth of a wide range of bacteria, viruses, and fungi. This is a significant advantage over other metals and materials traditionally used in medical settings. Studies have shown that copper surfaces can kill more than 99.9% of certain bacteria within just two hours of contact, making it an ideal choice for high-touch surfaces or environments requiring high standards of cleanliness.

This antimicrobial property is a major reason why copper tube manufacturers are increasingly integrating copper into medical products. Copper tube factories are expanding their production capabilities to meet the growing demand for antimicrobial copper tubes used in a variety of healthcare applications.

|

Material Type |

Antimicrobial Effect |

Corrosion Resistance |

Suitable Environments |

|

Pure Copper |

Kills over 99.9% of bacteria (within 2 hours) |

High corrosion resistance |

Medical gas delivery, medical devices |

|

Stainless Steel |

Limited antimicrobial effect |

Strong corrosion resistance |

Common in medical equipment and instruments |

|

Aluminum Alloys |

Weak antimicrobial effect |

Moderate corrosion resistance |

Used in non-critical equipment |

|

Plastic Tubing |

No antimicrobial effect |

High corrosion resistance |

Used in low-risk applications |

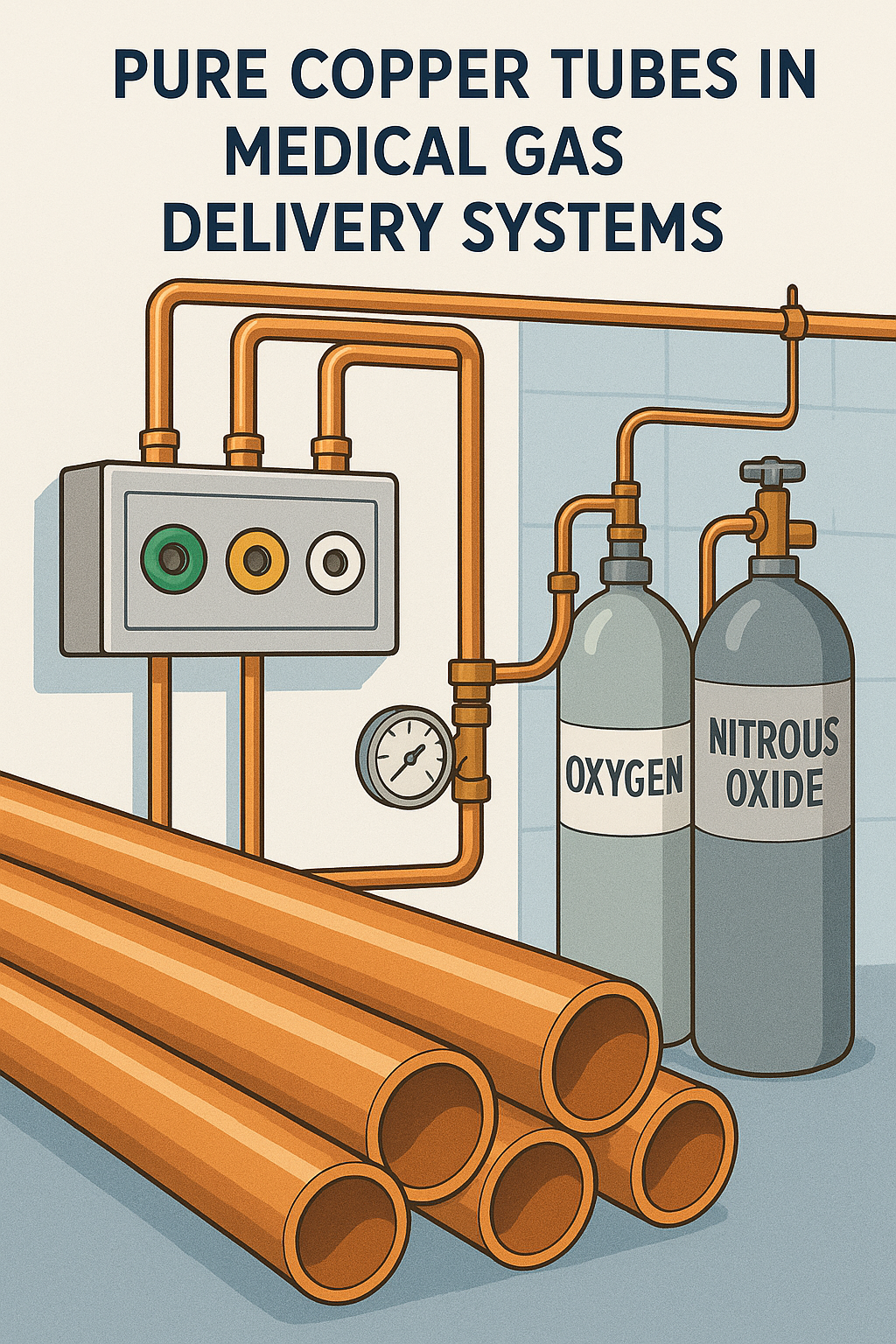

Pure Copper Tubes in Medical Gas Delivery Systems

One of the most significant uses of pure copper tubes in the medical field is in medical gas delivery systems. Hospitals and healthcare facilities rely on medical gas systems to deliver oxygen, nitrogen, nitrous oxide, and other critical gases to patients. These gases are used in a wide variety of treatments, including respiratory support, anesthesia, and in the operation of medical devices.

Copper has long been the material of choice for medical gas delivery systems due to its reliability, strength, and non-reactivity. Copper tubes are corrosion-resistant, which is critical in preventing the contamination of gases and ensuring that the gas remains pure and safe for use. In addition, the antimicrobial properties of copper help to prevent the growth of bacteria inside the tubes, which can otherwise lead to contamination of the gases being delivered to patients.

As copper tube manufacturers work to produce specialized copper tubing for medical use, they ensure that their products are manufactured to the highest standards of purity and quality. The copper tube factories that produce these tubes are equipped with advanced technologies to guarantee that the copper is free from impurities, ensuring both the safety and reliability of the tubes used in medical applications.

Copper tubes are also extremely durable, able to withstand high pressures without compromising their integrity. The flexibility and malleability of pure copper allow for easy installation and maintenance, which is essential in maintaining the functionality and safety of medical gas systems over time.

Copper’s Antimicrobial Properties: A Game-Changer in Sterility

One of the defining advantages of pure copper tubes in medical applications is their natural antimicrobial properties. The surface of copper is capable of killing a wide range of harmful microorganisms, including bacteria, fungi, and viruses. This is due to the copper ions that are released when copper comes into contact with moisture or microbial cells. These ions disrupt the cellular structure of microorganisms, leading to their death or inability to reproduce.

In medical environments, where maintaining a sterile environment is crucial, copper’s antimicrobial action can play a critical role in minimizing the risk of cross-contamination. For example, in hospital settings, where infection control is a top priority, copper tubes used in water, gas, or fluid delivery systems can significantly reduce the likelihood of microbial growth inside pipes or tubes.

The antimicrobial effects of copper are so well-documented that they have been recognized by regulatory bodies. The U.S. Environmental Protection Agency (EPA) has registered copper as an antimicrobial material, further solidifying its credibility as a safe and effective option for reducing microbial growth in healthcare settings.

As demand for antimicrobial copper products increases, copper tube factories are adapting their production processes to ensure that they meet stringent medical standards, producing high-quality copper tubes that can be used in hospitals, clinics, and other healthcare environments where sterility is paramount.

|

Material |

Antimicrobial Mechanism |

Antimicrobial Time |

Typical Applications |

|

Pure Copper |

Releases copper ions that disrupt microbial cells |

Kills 99.9% in 2 hours |

Medical gas delivery, equipment surfaces |

|

Stainless Steel |

No significant antimicrobial effect |

No antimicrobial effect |

General medical equipment |

|

Silver |

Silver ions bind to DNA of microbes, inhibiting growth |

4-6 hours |

Some medical devices and dressings |

|

Plastic |

No antimicrobial effect |

No antimicrobial effect |

Used in low-risk environments |

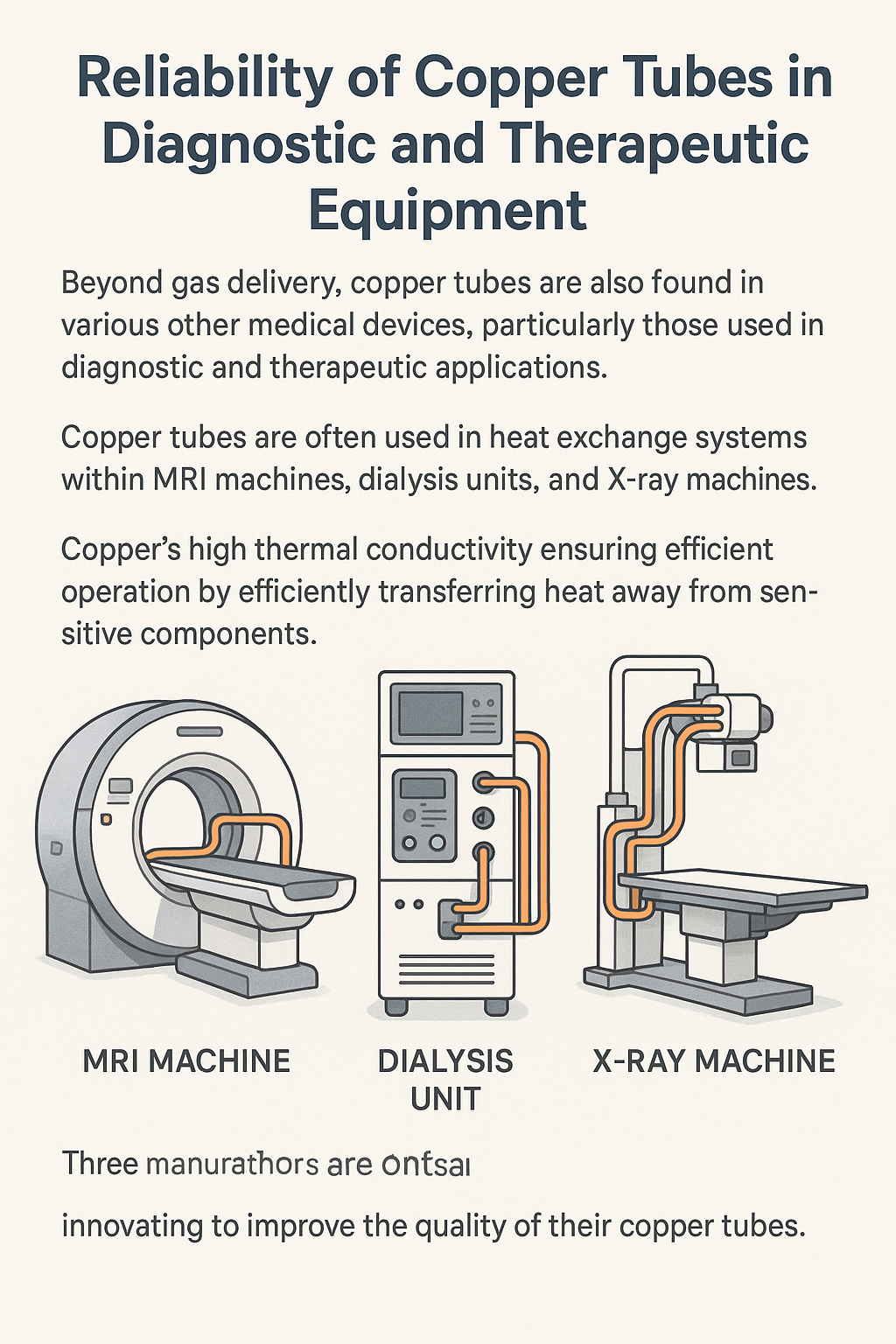

Reliability of Copper Tubes in Diagnostic and Therapeutic Equipment

Beyond gas delivery, copper tubes are also found in various other medical devices, particularly those used in diagnostic and therapeutic applications. For instance, copper tubes are often used in heat exchange systems within medical equipment like MRI machines, dialysis units, and X-ray machines. The high thermal conductivity of copper ensures that these machines operate efficiently and safely by efficiently transferring heat away from sensitive components.

In addition to their thermal conductivity, copper’s reliability and long lifespan make it a dependable choice for medical equipment that requires constant use. Whether in life-support machines, diagnostic tools, or therapeutic devices, copper tubes provide the necessary performance and longevity that medical equipment demands. Their ability to maintain performance under varying temperature and pressure conditions is one of the key reasons for their widespread adoption in medical technology.

The quality and precision of copper tubes used in these medical applications depend heavily on the expertise and technology of copper tube manufacturers. Leading manufacturers are constantly innovating to improve the quality of their copper tubes, ensuring that they are capable of handling the complex demands of the medical sector.

Copper Tubes in Wound Healing and Drug Delivery

In recent years, researchers have begun exploring the use of copper in drug delivery systems and wound healing technologies. Copper ions have been shown to promote tissue regeneration and accelerate the healing process, particularly in chronic wounds or burn injuries. The antimicrobial properties of copper also play a role in preventing infections in wounds, ensuring that the healing process is not compromised by bacterial growth.

Copper-infused dressings, often combined with pure copper tubes, are gaining popularity as a means of delivering localized treatment. These dressings have been found to reduce the risk of infection and promote faster healing, making them an important tool in the treatment of open wounds, diabetic ulcers, and surgical incisions.

Copper tubes in drug delivery systems are similarly beneficial, particularly in targeted drug delivery, where the metal can help ensure that therapeutic agents are delivered precisely to the right area in the right amount. The ability of copper to act as both a material for delivery and a therapeutic agent itself is an exciting development that holds promise for the future of medical treatments.

Environmental and Economic Benefits of Copper in Medical Applications

Apart from its functional and health benefits, copper’s environmental and economic advantages are also significant. Copper is a highly sustainable material. It is 100% recyclable without any loss of performance, making it an environmentally friendly choice for long-term medical use. The recycling of copper helps reduce the need for new mining, which in turn helps conserve natural resources and reduces environmental impact.

From an economic standpoint, copper’s durability and antimicrobial properties can result in cost savings for healthcare facilities over time. Although copper tubes may have a higher initial cost than some alternatives, their longevity, resistance to corrosion, and ability to reduce hospital-acquired infections can lead to long-term savings in maintenance, repairs, and healthcare-associated infection prevention.

As demand for high-quality copper products increases, copper tube manufacturers are continuously improving their production processes to ensure that the tubes meet the rigorous standards of the medical industry while also being environmentally sustainable.

|

Medical Application |

Role of Copper Tubes |

Benefits |

|

Medical Gas Delivery Systems |

Copper tubes are used to deliver oxygen, nitrous oxide, and other gases to patients. |

Corrosion resistance ensures purity of gases and antimicrobial properties reduce infection risks. |

|

Diagnostic Equipment |

Copper tubes are used in MRI, X-ray machines, and dialysis units for heat exchange. |

High thermal conductivity ensures efficient heat transfer, enhancing the performance of equipment. |

|

Wound Healing and Drug Delivery |

Copper tubes are incorporated into copper-infused dressings for chronic wound healing and localized drug delivery. |

Copper ions promote tissue regeneration and prevent infection, accelerating the healing process. |

|

Life Support Machines |

Copper tubes are used in the cooling systems of life support machines, such as ventilators. |

Ensures safe temperature regulation and prolonged machine life. |

Challenges and Considerations in Using Copper Tubes in Medical Settings

Despite the many benefits, there are some challenges and considerations in using pure copper tubes in medical applications. One of the main challenges is cost. Pure copper is more expensive than some alternative materials, such as stainless steel or plastic. However, as the benefits of copper become more widely recognized, the cost differential may become less of an issue, particularly in critical healthcare settings where patient safety and long-term reliability are the top priorities.

Another challenge is the potential for corrosion in some environments, particularly in areas with high humidity or where copper is exposed to certain chemicals. However, advances in copper alloys and protective coatings have helped mitigate this issue, ensuring that copper tubes can withstand harsh environments.

Product Category

Content

- The Significance of Sterility in Medical Environments

- Pure Copper Tubes in Medical Gas Delivery Systems

- Copper’s Antimicrobial Properties: A Game-Changer in Sterility

- Reliability of Copper Tubes in Diagnostic and Therapeutic Equipment

- Copper Tubes in Wound Healing and Drug Delivery

- Environmental and Economic Benefits of Copper in Medical Applications

- Challenges and Considerations in Using Copper Tubes in Medical Settings

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文