The Copper Tube Industry Embraces New Opportunities: Driven by Innovation and Sustainable Development

With the rapid development of the global manufacturing industry and increasingly stringent environmental regulations, the copper tube industry is undergoing a significant transformation. In copper tube factory in particular, continuous technological innovation and improved production processes have transformed copper tube production from a simple metalworking process into a highly intelligent, environmentally friendly, and modern manufacturing process. As an indispensable foundational material in modern industry, copper tubes are widely used in fields such as construction, automotive, air conditioning, and electronics. In these applications, copper tubes maintain a core position due to their excellent thermal conductivity, corrosion resistance, and recyclability.

Technological Innovation Drives Improved Production Efficiency

In recent years, continuous innovation in copper tube production processes has been transforming the industry landscape. In particular, in terms of production equipment and automation technology, an increasing number of copper tube factories are adopting intelligent production lines, improving production efficiency and product consistency. Through precise control and data analysis, these efficient production lines not only minimize material waste but also enhance product quality consistency, ensuring that the copper tubes meet the most stringent standards for size, thickness, and surface quality during production.

For example, some copper tube factories have begun using 3D printing technology to produce precise copper tube samples and conduct virtual simulation testing, reducing the cost and time of traditional sample production. Smart factories based on the Internet of Things (IoT) are becoming the future development direction of the copper tube industry, optimizing production processes and equipment maintenance through real-time monitoring and data analysis.

|

Category |

Innovation & Measures |

Impact & Effects |

|

Production Equipment & Automation Technology |

Adoption of intelligent production lines and automation technology to precisely control the production process. |

Increased production efficiency, reduced material waste, and improved product consistency. |

|

3D Printing Technology |

Use of 3D printing technology to produce precise copper tube samples and conduct virtual simulation testing. |

Reduced cost and time in traditional sample production. |

|

Smart Factories & IoT |

Smart factories based on IoT technology, optimizing production processes through real-time monitoring and data analysis. |

Optimized production processes and equipment maintenance, enhancing factory intelligence. |

|

Copper Recycling |

Use of recycled copper in production and promotion of closed-loop recycling systems. |

Reduced raw material costs, minimized environmental pollution, and lowered natural resource consumption. |

|

Green Manufacturing |

Adoption of environmentally friendly production processes, such as using clean energy and reducing waste emissions. |

Reduced energy consumption and waste emissions, complying with increasingly stringent environmental regulations. |

Sustainability Becomes a Core Industry Issue

Environmental protection has been a major challenge facing the copper tube industry in recent years. With increasingly stringent global environmental regulations, copper tube manufacturers need to take more measures to reduce energy consumption and waste emissions. Many copper tube factories have begun adopting more environmentally friendly production processes and equipment, such as using recycled copper in production, which not only reduces raw material costs but also significantly reduces environmental pollution.

Copper tube recycling is also highly valued within the industry. As a recyclable metal, copper recycling not only reduces production costs but also effectively reduces the consumption of natural resources. Many copper tube factories are actively promoting closed-loop recycling systems for copper tubes, forming a complete environmental chain from production to use and post-disposal recycling.

As the International Copper Association (ICA) points out in its report, "Copper Life Cycle," copper recycling and reuse are crucial components of its sustainability. Copper has a very long lifecycle and can be recycled and reused at nearly every stage of its lifecycle, which not only reduces the demand for new resources but also lowers the environmental impact of manufacturing. According to the ICA, copper recycling rates exceed 90%, and copper tube recycling is widely used worldwide, laying a solid foundation for the sustainable development of the copper tube industry (source).

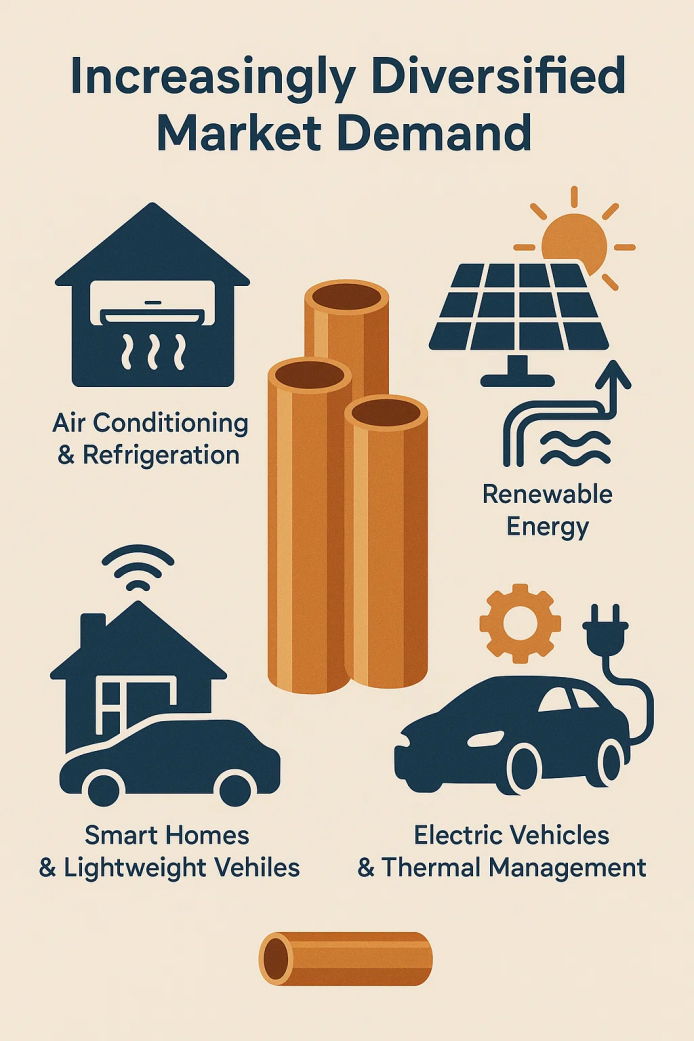

Increasingly Diversified Market Demand

Market demand in the copper tube industry is also undergoing significant changes. With global climate change and rising environmental awareness, demand for copper tubes in the air conditioning, refrigeration, and renewable energy sectors is increasing. In particular, in the new energy sector, copper tubes, due to their excellent thermal conductivity and corrosion resistance, have become a key material in energy devices such as solar and geothermal energy.

With the accelerated development of smart homes, lightweight vehicles, and electrification, the application scenarios of copper tubes are also expanding. High-performance copper tubes are not only core components for condensers and evaporators in home appliances, but also play a crucial role in the thermal management systems of new energy vehicles. This market is expected to continue to grow.

Ongoing Challenges and Future Outlook

Although the copper tube industry faces the dual challenges of technological innovation and environmental pressure, its prospects remain bright. With the global emphasis on green and intelligent manufacturing and sustainable development, the copper tube industry will continue to advance towards high efficiency, environmental protection, and intelligent manufacturing.

In the future, with further technological advancements and the promotion of environmental protection policies, the copper tube industry will play an even more important role in the global economic restructuring. Companies should closely follow industry trends and enhance their technological innovation capabilities and environmental protection standards to remain victorious in the fierce market competition.

Product Category

Related news

-

What is a thick-walled copper tube? Thick-walled copper tube, also known as seamless thick-walled copper tube, is a high-performance metal tube made o...

See Details -

Overview and Importance of Copper Capillary Tube In modern industrial equipment and precision control systems, miniaturization and high precision have...

See Details -

What is a copper tube? Analysis of material composition and basic characteristics Definition of copper tube Copper tube is a tubular object made of co...

See Details -

Understanding Copper Square Tubes: Composition, Grades, and Typical Applications Copper square tubes are specialized extrusions that combine the super...

See Details

English

English Español

Español 中文

中文